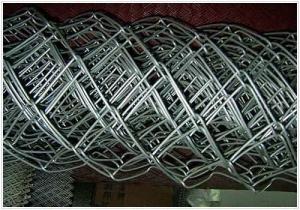

High Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q: Can steel wire mesh be used for screen printing?

- Indeed, screen printing can utilize steel wire mesh effectively. The prevalence of steel wire mesh as a screen printing medium stems from its robustness and potency. It furnishes a firm and steady platform for the ink to permeate, guaranteeing precise and uniform prints. Diverse mesh counts are accessible, permitting varying degrees of intricacy in the print. Moreover, steel wire mesh exhibits resistance to deterioration, rendering it an enduring choice for screen printing endeavors.

- Q: What are the different weaving patterns available in steel wire mesh?

- Steel wire mesh offers a variety of weaving patterns, each with its own distinct characteristics and uses. Some commonly used patterns include the following: 1. Plain Weave: The most basic and widely used pattern, plain weave involves interlacing wires in a simple crisscross manner. It is known for its strength, durability, and versatility. 2. Twilled Weave: In this pattern, each wire passes over two adjacent wires and under two others in a diagonal arrangement. Twilled weave offers a tight structure and high strength, making it ideal for applications requiring extra durability and resistance to wear and tear. 3. Dutch Weave: Dutch weave combines elements of plain and twilled weaves. It typically utilizes thicker warp wires and thinner weft wires, resulting in a tighter weave and smaller openings. Dutch weave is often used when precise filtration and separation are necessary. 4. Welded Wire Mesh: Unlike the previous patterns, welded wire mesh is not woven but rather created by welding individual wires at their intersections. This produces a strong, rigid mesh with consistent openings. Welded wire mesh finds common use in construction, fencing, and industrial settings. 5. Expanded Metal Mesh: Instead of weaving wires, expanded metal mesh is formed by cutting and stretching a metal sheet. This process creates interconnected diamond-shaped openings. Expanded metal mesh is lightweight yet sturdy, making it popular for architectural applications, filtration, and security purposes. These examples represent only a fraction of the weaving patterns available for steel wire mesh. The choice of pattern depends on specific requirements such as strength, filtration capabilities, and visual aesthetics.

- Q: Can steel wire mesh be used for filtration?

- Yes, steel wire mesh can be used for filtration. It is commonly used in various industries for filtering liquids and gases by trapping solid particles and allowing only the desired substances to pass through. The mesh size and wire diameter can be adjusted to achieve different filtration levels based on the specific application requirements.

- Q: What's the price of a low carbon steel wire mesh?

- Product development to the field of stainless steel wire mesh, I-Net, stainless steel mesh screens, finishing products and filter elements such as five series, mainly used in chemical, petroleum, textile, medicine, aviation, aerospace, construction of highway, railway, landscape protection, aquaculture, metallurgical machinery fields.

- Q: External wall plaster use steel wire mesh specification requirements?

- Wall light weight, energy saving effect is obvious, can reduce energy consumption, protect the main structure, but also extend the life of the building.

- Q: Can steel wire mesh be used for DIY projects?

- Yes, steel wire mesh can certainly be used for DIY projects. It is a versatile material that can be easily manipulated and cut to desired sizes. Steel wire mesh is commonly used for applications such as fencing, garden trellises, animal enclosures, and even as a support structure for concrete projects. Its strength and durability make it suitable for various DIY projects, providing stability and reliability in construction.

- Q: What are the cost considerations for steel wire mesh?

- There are several factors to take into account when considering the costs of steel wire mesh. The cost of the mesh will be significantly influenced by its size and dimensions. Larger and more intricate designs will generally be more expensive than smaller and simpler ones. The thickness and grade of the steel used in the mesh will also impact the cost. Thicker and higher-grade steel will typically be more expensive due to the increased material cost and potential for higher manufacturing expenses. Another crucial consideration is the quantity of steel wire mesh required for a project. Purchasing in bulk or larger quantities may often result in volume discounts and lower unit costs. Conversely, smaller quantities may lead to higher prices due to increased handling and packaging costs. Moreover, the cost of steel wire mesh can be affected by the complexity of the manufacturing process. Certain designs may require more intricate weaving or welding techniques, which can increase labor and production expenses. Additionally, the need for specialized equipment or tools during manufacturing can contribute to higher costs. Transportation and delivery costs should also be taken into account. The weight and size of the steel wire mesh can impact shipping expenses, particularly for long-distance transportation. Lastly, the cost of steel wire mesh can be influenced by market conditions and fluctuations in the price of steel. As steel is a commodity, its price can vary based on supply and demand factors, as well as global economic conditions. Therefore, it is crucial to monitor market trends and consider potential price changes when evaluating the overall cost of steel wire mesh.

- Q: What are the different wire mesh opening shapes available for steel wire mesh?

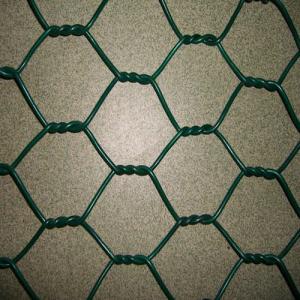

- There are several different wire mesh opening shapes available for steel wire mesh, each with its own unique characteristics and applications. 1. Square: This is the most common and basic opening shape for steel wire mesh. It features evenly spaced wires intersecting at right angles, creating square openings. Square wire mesh is versatile and widely used in various industries such as construction, filtration, and mining. 2. Rectangular: Similar to square wire mesh, rectangular openings have longer sides and are commonly used when a higher aspect ratio is required. This shape is often used in applications where a greater amount of material needs to be filtered or screened. 3. Hexagonal: Also known as hex wire mesh, this shape features hexagonal openings formed by interlocking wires. Hexagonal mesh is commonly used for lightweight fencing, poultry enclosures, and gabion walls due to its flexibility and strength. 4. Diamond: Diamond-shaped openings are created by intersecting wires at acute angles. This shape provides excellent strength and is commonly used for security fencing, machine guards, and architectural applications. 5. Round: Round wire mesh features circular openings and is typically used for filtration applications, such as separating solids from liquids or gases. This shape is also commonly used in decorative applications due to its aesthetically pleasing appearance. 6. Slotted: Slotted wire mesh has elongated openings that are typically rectangular or oblong in shape. This type of mesh is often used for architectural purposes, such as building facades or decorative panels, as well as for sorting or sifting materials. These are just a few of the most common wire mesh opening shapes available for steel wire mesh. The choice of opening shape depends on the specific application requirements, including desired strength, filtration capabilities, and aesthetics.

- Q: Is steel wire mesh corrosion-resistant?

- Steel wire mesh is resistant to corrosion, particularly when it is constructed from stainless steel. Stainless steel comprises chromium, which generates a safeguarding oxide layer on the metal's surface. This oxide layer functions as a shield against corrosive substances, preventing the steel wire mesh from rusting or corroding. Nevertheless, it is crucial to acknowledge that the extent of corrosion resistance may vary depending on the precise grade of stainless steel employed. Furthermore, environmental conditions and exposure to specific chemicals can also impact the corrosion resistance of the steel wire mesh.

- Q: Is steel wire mesh suitable for pet enclosures?

- Yes, steel wire mesh is suitable for pet enclosures. Steel wire mesh is a durable and sturdy material that provides excellent security and containment for pets. It is resistant to chewing and scratching, making it ideal for containing animals such as dogs, cats, or rabbits. Additionally, steel wire mesh allows for good ventilation and visibility, ensuring that pets have adequate air circulation and owners can easily keep an eye on them. It is also easy to clean and maintain, making it a practical choice for pet enclosures. However, it is important to ensure that the mesh is properly installed and there are no gaps or loose ends that pets could potentially escape through or get injured on. Overall, steel wire mesh is a reliable and suitable option for pet enclosures.

Send your message to us

High Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords