STAINLESS STEEL COILS SURFACE TREATMENT NO.1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STAINLESS STEEL COILS

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

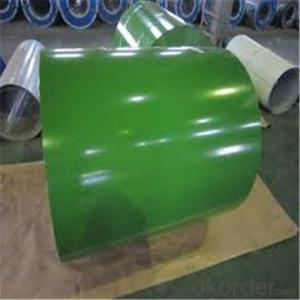

Commodity

STAINLESS STEEL COILS

Technical Standard: Steel Grade &Standard:J1

Surface Treatment:NO.1

Hot rolled Annealed and Pickled(HRAP)

Grade: J1 , Prime quality

Mill Edge. No connection point in each coil.Component: Ni:1% , Cu: 0.65-0.9%, Cr: 13%, Mn: 10–12%, C: 0.09-0.12%

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- There are more than 10,000 different steel alloys that have been specified and used for different purposes. They cover a huge range of mechanical properties. For silver, are you talking about pure silver, or a silver alloy with a additives to improve its mechanical properties? Typical values for mild steel at room temperature are E = 210 GPa, G = 80 GPa (source: 30 years working as a mech. engineer) Wikipedia gives E = 80GPa, G = 30GPa for pure silver (temperature not specified). Silver alloys may be very different from those values. The properties will also depend on the metal forming process (e.g. drawn wire, annealed, etc). NB some alloys with silver in their common name contain no silver at all.

- Q: How long can steel coils be stored before they need to be used?

- Steel coils can typically be stored for an extended period of time without any significant degradation. However, it is recommended to use them within 6 to 12 months to prevent any potential corrosion or damage.

- Q: How many pounds can steel lift?

- It depends on the type of steel and the geometry of the item.

- Q: How are steel coils used in the manufacturing of fasteners?

- Steel coils are used in the manufacturing of fasteners as they provide a continuous and reliable source of raw material. These coils are typically processed through a series of steps, including cutting, shaping, and forming, to create various types of fasteners such as bolts, screws, and nails. The high strength and durability of steel make it an ideal material for fasteners, ensuring their performance and longevity in a wide range of applications.

- Q: How are steel coils inspected for edge quality?

- Steel coils are inspected for edge quality through visual examination, measuring thickness and width, and conducting various tests such as bend tests and surface inspections.

- Q: I work at a tool store. I told my boss last week we needed more pruning shears so he did get more of all kinds. Thing is out of all of the shears he brought Two of different kinds say they are made out of Japanese steel. I have never heard of Japanese steel so now i ask you (the public) whats the difference between it and steel from the US or any other country? Those shears are worth more then the ones he gets from Mexico and China and even more than Black and Decker, Fiskars, etc but not more then Corona brand ones.

- I doubt japanese steel has any special quality in its own, but they might just be higher quality shears. For example, Chinese qualities are good depending on what they are, but are usually not professional made with the greatest equipment. Same for Mexico. The company that makes them might just put more effort into making sturdier and sharper shears and thus make them more expensive, but Corona might make them a bit better so they are priced less than Corona's.

- Q: i like stainless steel guns, especially the SW 686 .357, i plan on getting one but my question is would polishing the stainless steel make the gun more prone to corrosion over leaving it as it is? and will the polished surface appear uneven after use and sitting? obviously all metal takes some sort of upkeep but is polished more high maintenance than non-polished?

- Stainless Revolver

- Q: How are steel coils processed for slitting or edge conditioning?

- Steel coils are processed for slitting or edge conditioning through a series of steps. First, the coils are unwound and flattened using a decoiler. Then, they are fed through a slitting machine, which cuts the wide coil into smaller strips of the desired width. These strips are then recoiled to create narrower coils. For edge conditioning, the coils are passed through an edge trimmer, which removes any rough or uneven edges. Finally, the coils are recoiled again and packaged for further use or distribution.

- Q: How are steel coils coated to prevent rust and corrosion?

- Steel coils are coated to prevent rust and corrosion through a process called galvanization. This involves immersing the coils in a bath of molten zinc, which forms a protective layer on the steel surface. This zinc coating acts as a barrier, preventing oxygen and moisture from coming into contact with the steel, thus reducing the risk of rust and corrosion.

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knife

Send your message to us

STAINLESS STEEL COILS SURFACE TREATMENT NO.1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords