Aluzinc Galvalume Metal Coil for roofing and siding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ALUZINC Steel Sheet is carbon steel sheet coated with aluminum-zinc alloy by a continuous hot-dip

process. The nominal coating composition is 55% aluminum and 45% zinc. A small but important addition

of silicon is included in the coating alloy. It is added not to enhance the corrosion performance, but to

provide good coating adhesion to the steel substrate when the product is roll-formed, drawn, or bent during

fabrication.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

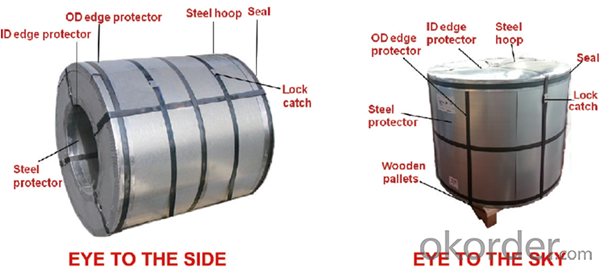

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Which steels were origianally designed to be used to cut and shape metals and other materials?- alloy steel- high carbon steel- carbide steel- tool steelthanks

- In your choices carbide steels are used for milling and drilling purposes and high speed steel are used in lathe operations. For shaping the tools, tool grinding machines are used and for initial sharing dyes are used.

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as the core component of the motor's electromagnet. The coils are wound around an iron core to create a magnetic field when electricity flows through them. This magnetic field interacts with other components in the motor to generate mechanical power, allowing the motor to function efficiently.

- Q: I want a good quality, big, strong, steel knife but I want it to be a good price, say around $30 or less, $60 at the most. please add links.

- DAGS for combat knife

- Q: i am debating weather to get the hercules rmx or the steel and from what i have read, the only differences between them is the rmx has a sound card (built in interface-to connect to the computer, correct me if im wrong) and that the steel has more effects. however, i cannot find out which effects it has so it would be a big help if someone can answer this for me.thanx

- I guess that since Steel doesn’t have headphones connection and a built-in soundcard, one won’t be able to play a track on one deck and prelisten the track on the other without using an external usb soundcard, right? I was wondering what’s the point in releasing a product like this if you also have to buy a bunch of equipment to be able to do sth “fondamental”: play while preparing your next song. However since the steel is meant for DJ’s who already have a great soundcard, but I don’t see why a Steel+sound card is ONLY for pro’s. Yes it’s designed for pro’s but you can use it as a beginner. Some consoles you also need to consider: Hercules Steel/RMX, Numark OMNI/Steath. It's all personal decision. Peace, Love Happiness

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel ___ Tompkins xavier jax stone blaise/blaze navarro dialo zorion soloman eron muron darko vincent wolf giovanni ryker/rykeir orvall oryan/orian isadore reese axel/axl xander/zander zane zeke dane xan/zan grayson griffin trayton urban sterling - probably wouldn't sound good with steel but its another choice you can have STOP HATING SHE SAID SHE DIDNT LIKE COMMON NAMES!

- Q: Which one is stronger steel or metal ( for bow and arrows) please answer I need it for a book I'm writing

- hi Asking this question in engineering category would give you the following answer steel is a subcategory of metals moreover steel is iron with some other additions( mainly carbon) strong in the engineering sense is not a specific word..i mean we , in engineering, have many scales to categorize metals ( which include steel)..like hardness,corrosion,elasticity, and even heat conductivity...every metal could be strong in some and weak in other but i can understand that you are not an engineering type :) that's why here's a special answer for you steel usually has the silver shiny color ( i am not sure all grades of steel have this color)...it would be more EPIC to use steel bow and arrows... if it's a fictitious books...you can just use Iron or any name you can made up... You can search....how did the ancients make their bows and arrows? thanks :)

- Q: How are steel coils used in the manufacturing of automotive suspension systems?

- Steel coils are used in the manufacturing of automotive suspension systems as they provide the necessary support and stability to withstand the weight and movement of the vehicle. These coils are typically shaped into springs and installed in the suspension system to absorb shocks, maintain proper ride height, and improve overall handling and comfort for the driver and passengers.

- Q: 1943 steel pennies

- if you collect coins, you need to learn that they must never be cleaned. cleaning, while it might make them look pretty, ruins their value as a collectable. ask your coin dealer.

- Q: I am making a permanent magnet, just for fun. I am trying to find the best grade of steel to do so with.

- The type of steel you require is Steel ( Iron + Carbon, mainly.),{many different types of steel } with a high Cobalt and Nickel content. These alloyed together give the best Permanent Magnets, mainly due to their own individual magnetic properties / characteristics being retained in the Alloy. All 3 metals can be magnetised by there own, but Cobalt is known to cause cancer. Nickel, is poisonous and can also cause sever Dermatitis and the destruction of skin tissue.But when alloyed together with Iron they are pretty harmless. Interesting thing is, All of these metals (in this case Elements) can share the same Mass Number ( 60 ). And yet are totally different in their other properties beside Magnetism. Cobalt - Samarium - alloys, create some of the worlds most powerful permanent magnets. And were used in medicine, But are now superseded by Neodymium magnets which are employed instead. Edit; What you could try is, mild steel which is widely available and easily found. . The steels mentioned above are pretty exclusive materials and I personally would not know how to test for their contents, of which they are made from. Soft Iron is good for making electro-magnets if you fancy a go at making one. .

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- The reason the steel wool catches fire is because the strands of steel are so fine and they have a high resistance. The thin strands get to red-hot very quickly, compared to larger gauge copper wire which has lower resistance and can dissipate the heat over its larger mass. When you connect the battery to the wire first, then touch the steel wool, you are making solid contact with the steel wool and your hand makes sure that the wire stays in contact. The current continues to flow and the wool heats up. When you connect the wire to the steel wool first, as soon as you connect the battery the current melts that tiny bit of steel wool touching the wire and electrical contact is lost. The current stops flowing. No fire. If you want to connect the wire first and not have to hold it, you have to make sure that the current keeps flowing, perhaps by using a braided copper wire and spreading out the individual strands to make multiple contacts. Either that, or remove the insulation from a longer section of the wire and make sure that the entire un-insulated part of the wire is in contact with the steel wool. Maybe even weigh it down. Remember that any strands of steel wool touching that wire will melt as soon as the current starts, so you have to make sure that the wire will maintain contact somehow, the same way that your hand pushes the wire against it.

Send your message to us

Aluzinc Galvalume Metal Coil for roofing and siding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords