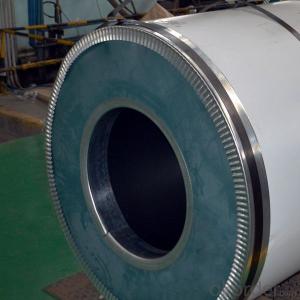

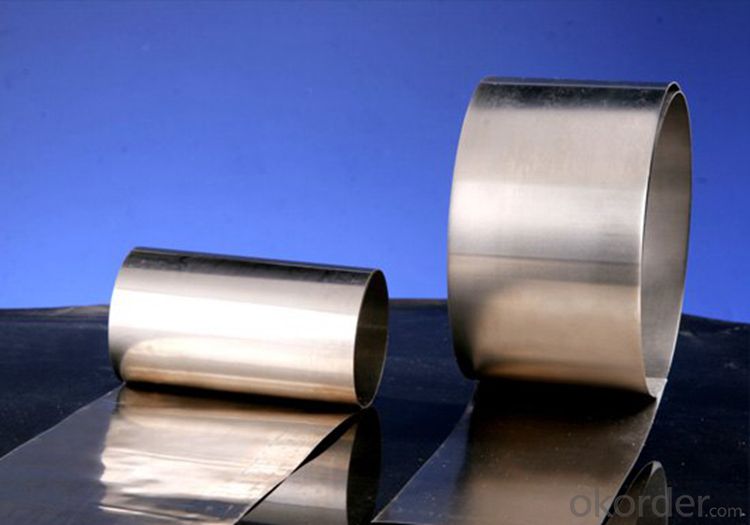

Stainless Steel Coils,Cold Rolled Stainless Cold Rolled Stainless Steel Finish Grade 304

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What does "80 wire" stainless steel plate mean? How much more expensive than the average stainless steel plate?

- Stainless steel terminology, the general thickness of C to calculate the negative difference, the 1 C is 0.01MM, so 80C is 0.8MM. 0.8MM thick stainless steel with different thickness, different prices, generally about Yuegui thin.

- Q: Can stainless steel sheets be used for outdoor sculptures?

- Indeed, outdoor sculptures can make use of stainless steel sheets. Due to its remarkable resistance to corrosion, stainless steel is exceptionally suitable for outdoor scenarios where sculptures are subjected to diverse weather conditions. It can endure rain, snow, heat, and UV radiation without compromising its strength or deteriorating. Moreover, stainless steel boasts a sleek and contemporary appearance that can augment the sculpture's visual impact. Its robustness and ability to repel rust render it a favored selection for outdoor sculptures found in parks, gardens, and public areas.

- Q: Are stainless steel sheets suitable for storage tanks?

- Indeed, storage tanks find stainless steel sheets to be a suitable choice. Due to its remarkable durability and resistance to corrosion, stainless steel emerges as an optimal selection for housing a range of substances. Its ability to ward off rust and corrosion ensures that the tank remains intact and devoid of any leaks. Furthermore, stainless steel boasts a high strength-to-weight ratio, thereby allowing for the construction of sizable storage tanks without compromising structural integrity. Moreover, stainless steel proves to be easily maintainable and cleanable, rendering it a hygienic option for storing food-grade or pharmaceutical substances. All in all, stainless steel sheets present themselves as a dependable and enduring alternative for storage tanks across various industries.

- Q: Stainless steel plate how to distinguish between good and bad, there are several thick?

- 1. identification of imported or steel ordered stainless steel materials, usually only in accordance with the import or steel quality certificate, check the steel or packaging on the mark can be.The certificate of quality is the confirmation and guarantee of the inspection result of the product by the supplier. Therefore, the certificate of quality not only indicates the name, specifications, delivery number, weight and delivery status of the materials, but also the entire inspection results of the required guarantee items.

- Q: What is the modulus of elasticity of stainless steel sheets?

- The stiffness or rigidity of a material can be determined by its modulus of elasticity, which is commonly referred to as Young's modulus. In the case of stainless steel sheets, the modulus of elasticity usually falls within the range of 190 to 200 gigapascals (GPa). Nevertheless, it is crucial to acknowledge that the modulus of elasticity is subject to variation based on factors like the precise type and grade of stainless steel, as well as temperature and strain rate.

- Q: Inspection method for stainless steel welding

- 1) measurement, in strict accordance with the requirements of the drawings, and to ensure that within tolerance. Along the column, a top cover, and frame, beam should be straight, without distortion, the straightness (nonstraightness) should meet the requirements on the table diagonal method.2) no distortion, swing, rotation or displacement are allowed in the structures which are completely fixed

- Q: How do I prevent finger marks on stainless steel sheets?

- To prevent finger marks on stainless steel sheets, you can try a few simple steps. Firstly, make sure to clean the sheets regularly using a mild detergent or stainless steel cleaner to remove any existing fingerprints. Next, consider applying a protective coating or film specifically designed for stainless steel surfaces, which can provide a barrier against smudges and fingerprints. Additionally, try to handle the sheets with clean and dry hands to minimize the transfer of oils and dirt. Finally, consider using microfiber or lint-free cloths for cleaning instead of rough materials that can leave scratches or streaks.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness range available for stainless steel sheets typically varies from 0.4mm to 6mm, depending on the specific requirements and applications.

- Q: How do you calculate the bending radius for stainless steel sheets?

- To calculate the bending radius for stainless steel sheets, you need to consider several factors. Firstly, determine the thickness of the stainless steel sheet. Thinner sheets require smaller bending radii, while thicker sheets can handle larger radii. Next, identify the type of stainless steel being used. Different grades of stainless steel have varying levels of ductility, which affects their ability to be bent. Higher ductility allows for smaller bending radii. Additionally, consider the desired angle of the bend. The sharper the angle, the smaller the bending radius needed. To calculate the bending radius, you can use the following formula: Bending Radius = (2 x Sheet Thickness) + (Bend Angle x Sheet Thickness) For example, if you have a stainless steel sheet with a thickness of 0.5mm and you want to achieve a 90-degree bend, the bending radius would be: Bending Radius = (2 x 0.5mm) + (90 x 0.5mm) = 1mm + 45mm = 46mm It is important to note that this formula provides a general guideline and may vary depending on the specific properties of the stainless steel being used. It is always recommended to consult technical specifications or manufacturers' guidelines for accurate bending radius calculations.

- Q: What is stainless steel plate wire?

- But in the stainless steel industry said decimillimeter, such as stainless steel plate with the thickness of 1mm, the tolerance of 0.91 plus or minus 1 wire, a tolerance of plus or minus 0.01mm 0.91mm. That is to say here is actually in mathematics centimillimeter decimillimeter.1 wire =0.01 mm

Send your message to us

Stainless Steel Coils,Cold Rolled Stainless Cold Rolled Stainless Steel Finish Grade 304

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords