Stainless Steel Coil /Sheet in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

stainless steel coil

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, BS 1449, DIN17460, DIN 17441

2. Grade: 200series&300series&400series

3. Thickness: 0.23mm-0.8mm

4. Diameter: 115-560mm

5. Length: according buyer require

6. Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

7. Manufacture technology: cold drawn/cold rolled/hot rolled

1) Product feature:

| 1. Commordity: | stainless steel coil, stainless steel sheet |

| 2. Thickness: | 0.3mm~5.0mm |

| 3. Width: | 6mm~500mm, 1219mm, 1500mm |

| 4. Surface: | Shiny surface, 2B, 2R, BA |

| 5. Standard: | ASTM A240 |

| 6 Finishing: | Cold rolled + annealed |

| 7. Materials: | 301, 304, 304L, 316, 316L, 316Ti, 317L, 321, 347, S31803 (F51), S32205 (F60), 32750 (F53), S32760 (F55), 17-7PH ( 631), 904L |

| 8. Material origin: | TISCO, POSCO, LISCO, ZPSS, Bao steel, Krupp etc |

| 9. Application: | Flexible metal hose, air duct, Gasket, tower packing, power cable & oil well, washer, packing, heat exchanger, conveyor belting |

| 10. Coil ID: | 300MM, 400mm, 500mm as per customers’ request |

| 11. Coil weight: | as per client’s requirement. |

| 12. Delivery time | Be ready for shipment within 15~20 days upon receipt PO |

| 12. Package: | Plywood boxes. ( See pictures below ) |

| 13. Certificate: | ISO, BV, SGS, Mill test certificate |

| 14. Product quality: | Good & prime |

| 15. More information: | Contact Vivian (MP/WhatsApp/Viber: 0086-13921352562) skype: vivian.316L |

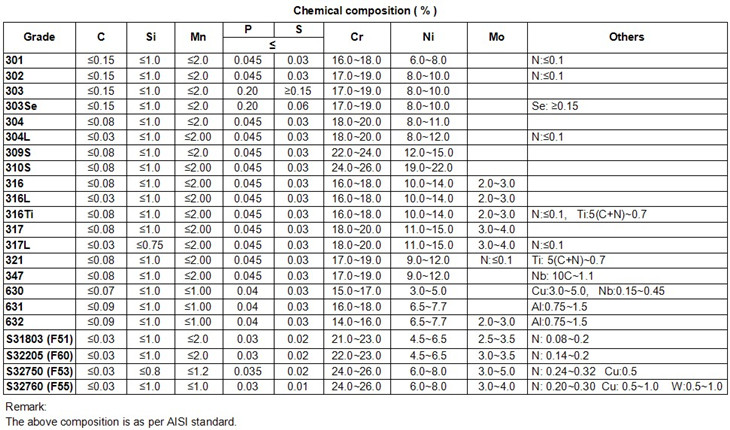

2) Chemical composition:

3) Product picture display:

- Q: What are the standard dimensions of stainless steel strips?

- The standard dimensions of stainless steel strips can vary depending on the manufacturer and specific application. However, common dimensions for stainless steel strips range from 0.1mm to 6mm in thickness and 10mm to 600mm in width.

- Q: Can stainless steel strips be used in automotive applications?

- Yes, stainless steel strips can be used in automotive applications. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various automotive components such as exhaust systems, trim, and brackets.

- Q: What is the price range for stainless steel strips?

- The price range for stainless steel strips can vary depending on various factors such as the thickness, width, and grade of the stainless steel. Generally, stainless steel strips can range in price from around $1 to $10 per square foot. However, for more specialized or high-quality stainless steel strips, the price can go higher. It is important to consider the specific requirements and specifications of the stainless steel strips needed to determine an accurate price range. It is recommended to contact suppliers or manufacturers directly to get a more precise and updated pricing information.

- Q: How does the price of stainless steel strips vary?

- The price of stainless steel strips can vary based on factors such as the grade of stainless steel, market demand and supply, production costs, and global economic conditions. Higher-grade stainless steel strips tend to have a higher price due to their superior quality and corrosion resistance. Additionally, fluctuations in raw material prices, such as nickel and chromium, can impact the overall cost of stainless steel strips. Market dynamics and competition also play a role in determining the pricing of stainless steel strips, with supply and demand imbalances affecting the prices.

- Q: What are the common surface finishes for stainless steel strips?

- Common surface finishes for stainless steel strips include: 1. Mill Finish: This is the basic finish that is achieved after the stainless steel strip has been hot or cold rolled. It has a dull, non-reflective appearance. 2. Brushed Finish: This finish is created by brushing the stainless steel strip with abrasive materials, resulting in a textured appearance. It helps to hide surface imperfections and gives the strip a satin-like finish. 3. Polished Finish: The stainless steel strip is mechanically polished to create a smooth, reflective surface. This finish is commonly used for decorative purposes and is available in various levels of polish, such as mirror polish or satin polish. 4. Embossed Finish: In this finish, the stainless steel strip is passed through embossing rollers that create raised or sunken patterns on the surface. It adds texture and visual interest to the strip. 5. Patterned Finish: Stainless steel strips can be patterned using various techniques, such as etching or laser engraving. This creates decorative patterns or designs on the surface, giving the strip a unique and distinctive look. 6. Coated Finish: Stainless steel strips can be coated with a thin layer of another material, such as a polymer or a metal, to enhance its appearance or provide additional protection against corrosion. These are some of the common surface finishes for stainless steel strips, each offering different aesthetics and functionality to suit various applications.

- Q: Can stainless steel strips be used in the automotive industry?

- Yes, stainless steel strips can be used in the automotive industry. Stainless steel is a versatile and durable material that offers several advantages for automotive applications. It has excellent corrosion resistance, which is crucial for withstanding harsh environmental conditions and exposure to road salts or chemicals. Stainless steel strips are also resistant to heat and can withstand high temperatures, making them suitable for various automotive components such as exhaust systems and engine parts. Additionally, stainless steel strips have high strength and can provide structural support and reinforcement for automotive frames and body panels. They can also be used for decorative purposes, enhancing the aesthetic appeal of vehicles. Overall, stainless steel strips are a reliable and valuable material choice for the automotive industry.

- Q: Are stainless steel strips suitable for decorative embossing?

- Yes, stainless steel strips are suitable for decorative embossing.

- Q: How do stainless steel strips perform in extreme cold temperatures?

- Stainless steel strips perform exceptionally well in extreme cold temperatures due to their inherent resistance to corrosion, durability, and ability to maintain their mechanical properties.

- Q: Are stainless steel strips resistant to acids and alkalis?

- Stainless steel strips have a general resistance to acids and alkalis. Chromium, found in stainless steel, creates a passive oxide layer on the metal's surface. This oxide layer serves as a protective barrier, safeguarding the steel from corrosion. Consequently, stainless steel exhibits strong resistance to both acids and alkalis. Nevertheless, the level of resistance may fluctuate depending on the stainless steel's specific grade and composition. Certain grades might demonstrate higher resistance to particular acids or alkalis compared to others. It is advisable to seek guidance from the manufacturer or supplier for precise information regarding the resistance of a specific stainless steel grade to acids and alkalis.

- Q: Are stainless steel strips heat resistant?

- Stainless steel strips possess the characteristic of being resistant to heat. This material is renowned for its capacity to endure elevated temperatures without undergoing any deformation or harm. Its melting point is considerably high, enabling it to uphold its strength even under extreme thermal conditions. Consequently, stainless steel strips are highly suitable for a wide range of uses that involve exposure to heat, including industrial processes, cooking utensils, and automotive components. Moreover, the heat resistance of stainless steel significantly contributes to its durability and long-lasting nature, as it can endure thermal stress and maintain its structural integrity throughout the passage of time.

Send your message to us

Stainless Steel Coil /Sheet in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords