Stainless Steel Coil Price in Wuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications about stainless steel coils

Item Name | Stainless steel coils |

Grade Steel | 201/202/301/304/304L/310S/316/316L/316Ti/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Brand | TISCO,BAOSTEEL,LISCO,JISCO,ZPSS,POSCO |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush,Mirror,Polish ect |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

MOQ | 1 TON |

Delivery | 5 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

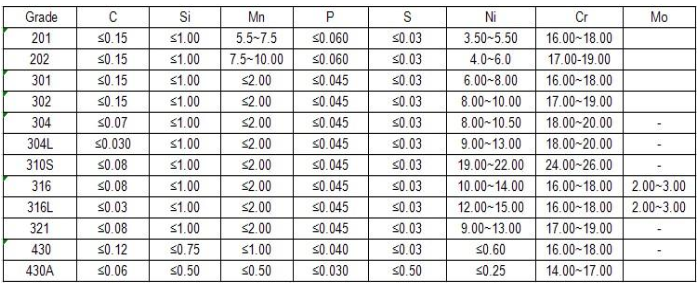

2. Chemical Composition about stainless steel coils

3. Surface--stainless steel coils

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

4.Product Photos

Packaging & Shipping

5.Packaging--stainless steel coils

Our Services

6.Manufacturing Process of Stainless Steel Sheet/Plate:

Raw materials are sending to hot rolling units for rolling into different sizes.

→Hot rolled material is annealing in cold rolled annealing furnace and pickling in acid.

→All mill rolls are grinded on precision grinding machine with proper chamfering after first shift operation.

→All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

→These sheets are again annealing and are sent to straighten machine for straightening.

→Inspections are done at various stages. Keep proper control overall internal process via rolling, annealing and pickling by our experienced staff.

8.Application--stainless steel sheet/plate

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic – cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Transport – exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3.Oil and Gas – platform accommodation, cable trays, subsea pipelines.

4.Medical – Surgical instruments, surgical implants, MRI scanners.

5.Food and Drink – Catering equipment, brewing, distilling, food processing.

6.Water – Water and sewage treatment, water tubing, hot water tanks.

7.General – springs, fasteners (bolts, nuts and washers), wire.

8.Chemical/Pharmaceutical – pressure vessels, process piping.

9.Architectural/Civil Engineering – cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports

- Q: How do stainless steel strips perform in the presence of chlorine?

- Chlorine generally does not affect the performance of stainless steel strips. Stainless steel is renowned for its ability to resist corrosion and forms a protective layer of chromium oxide on its surface. This layer acts as a barrier, preventing chlorine from corroding the steel underneath. However, under certain circumstances, stainless steel can still experience localized corrosion, such as pitting and crevice corrosion, when exposed to high levels of chlorine or other corrosive substances. Therefore, it is crucial to consider the specific grade of stainless steel used, as some grades have higher resistance to chlorine. Additionally, proper maintenance and cleaning procedures should be followed to ensure the durability and effectiveness of stainless steel strips in environments with high chlorine content.

- Q: Can stainless steel strips be used in the production of kitchen utensils?

- Yes, stainless steel strips can be used in the production of kitchen utensils. Stainless steel is a popular choice for kitchen utensils due to its durability, resistance to corrosion, and ease of cleaning. Stainless steel strips can be shaped and formed into various utensils such as spoons, forks, knives, and spatulas, making them an ideal material for kitchen utensil production.

- Q: Can stainless steel strips be used in the production of electrical connectors?

- Indeed, the utilization of stainless steel strips is feasible in the manufacturing process of electrical connectors. Notably, stainless steel is an incredibly adaptable substance that presents exceptional mechanical attributes, encompassing notable strength, durability, and resistance to corrosion. Consequently, these attributes render it appropriate for a wide range of applications, including the development of electrical connectors. The malleability of stainless steel strips allows for the creation of connectors in precise forms and dimensions, thereby facilitating the achievement of meticulous tolerances. Moreover, the capacity of stainless steel to withstand oxidation and corrosion guarantees the durability and dependability of the connectors, even when exposed to demanding surroundings. In summary, stainless steel strips represent a viable selection for the production of electrical connectors.

- Q: Are stainless steel strips resistant to erosion?

- Indeed, erosion is highly unlikely to affect stainless steel strips due to their exceptional resistance. Composed of iron, chromium, and other elements, stainless steel is an alloy that possesses remarkable properties in terms of corrosion resistance. The presence of chromium in stainless steel results in the formation of a protective passive layer on its surface, effectively preventing any interaction between the metal and its surrounding environment. As a result, the chemical reactions, moisture, and exposure to different atmospheric conditions that typically cause erosion are rendered ineffective against stainless steel strips. Consequently, these strips are perfectly suited for a wide range of applications that necessitate erosion resistance, such as marine environments, chemical processing plants, and outdoor structures that are exposed to harsh weather conditions.

- Q: Can stainless steel strips be used for kitchen appliances?

- Indeed, kitchen appliances can make use of stainless steel strips. The durability, resistance to corrosion, and sleek look of stainless steel make it a popular choice for kitchen appliances. It offers a surface that is easy to clean and maintain, ensuring hygiene. To cover and safeguard different sections of kitchen appliances like refrigerator doors, dishwasher panels, oven fronts, and range hoods, stainless steel strips can be employed. Furthermore, these strips can be tailored to specific design needs in terms of thickness, width, and finish. In conclusion, stainless steel strips are a flexible and sensible choice for improving the appearance and functionality of kitchen appliances.

- Q: Are stainless steel strips resistant to pitting and crevice corrosion?

- Yes, stainless steel strips are highly resistant to pitting and crevice corrosion due to their composition and protective oxide layer.

- Q: What are the common uses of stainless steel strips in the aerospace fastener industry?

- Stainless steel strips are commonly used in the aerospace fastener industry for various purposes such as manufacturing aircraft components, assembling structures, and securing parts together due to their high strength, corrosion resistance, and durability. These strips are utilized in fasteners like bolts, nuts, screws, and rivets, ensuring the integrity and reliability of aircraft structures even in extreme conditions.

- Q: What are the recommended machining techniques for 111 stainless steel strips?

- To achieve optimal results when machining 111 stainless steel strips, it is important to consider the following techniques: 1. Cutting: Opt for a high-speed steel (HSS) or carbide-tipped saw blade for cutting stainless steel strips. These blades offer durability and hardness, enabling precise and efficient cuts. Additionally, using a lubricant during cutting helps reduce friction and heat buildup. 2. Drilling: When drilling holes in stainless steel strips, it is advisable to utilize cobalt or carbide drill bits. These materials can withstand the high hardness of stainless steel and maintain their sharpness over extended periods. To prevent overheating and extend the drill bit's lifespan, remember to employ a cutting lubricant. 3. Grinding: Achieve the grinding of stainless steel strips by employing various abrasive wheels, such as aluminum oxide or ceramic. These wheels are specifically designed to handle the hardness of stainless steel while providing a smooth and consistent finish. Ensure the use of a coolant during grinding to avoid overheating and maintain the strip's surface integrity. 4. Bending: When bending stainless steel strips, it is crucial to utilize proper tooling to prevent deformation or cracking. Employ a press brake or roller with rounded edges to achieve precise and uniform bends without causing damage to the strip. Additionally, annealing the strip before bending enhances its pliability and reduces the risk of cracking. 5. Welding: Various welding techniques, including TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas), can be used for welding stainless steel strips. Ensure the selection of a compatible filler material based on the specific grade of stainless steel being used. Preheating the strip before welding aids in reducing distortion and improving the quality of the weld. In conclusion, selecting the appropriate tools and techniques is paramount when machining stainless steel strips for optimal results. Consulting the manufacturer's guidelines or seeking advice from a professional machinist tailored to the specific grade of stainless steel being processed is highly recommended.

- Q: What are the different types of stainless steel strip alloys?

- Stainless steel strip alloys are categorized based on their chemical composition and properties, which determine their suitability for various applications. Here are some of the different types of stainless steel strip alloys: 1. Austenitic stainless steel: This is the most common type of stainless steel strip alloy, known for its excellent corrosion resistance. It contains high levels of chromium and nickel, which provide stability and durability. Austenitic stainless steel is non-magnetic and is often used in industries such as food processing, chemical, and pharmaceutical. 2. Ferritic stainless steel: Ferritic stainless steel strip alloys have a higher chromium content than other alloys. They are magnetic and possess good resistance to corrosion, heat, and stress. These alloys are commonly used for applications that require high strength and resistance to oxidation, such as automotive exhaust systems and appliances. 3. Martensitic stainless steel: Martensitic stainless steel strip alloys are hard and strong, making them suitable for applications that require wear resistance and high mechanical properties. They have a higher carbon content, which allows them to be hardened through heat treatment. These alloys are commonly used in cutlery, surgical instruments, and turbine blades. 4. Duplex stainless steel: Duplex stainless steel strip alloys have a mixed microstructure of austenite and ferrite, offering a balanced combination of strength and corrosion resistance. They have higher levels of chromium and molybdenum, making them highly resistant to stress corrosion cracking and pitting. Duplex stainless steel is commonly used in chemical processing, oil and gas, and marine environments. 5. Precipitation-hardening stainless steel: These alloys can be heat treated to achieve high strength and hardness. They contain elements such as nickel, copper, and aluminum, which form precipitates during the heat treatment process, resulting in increased strength. Precipitation-hardening stainless steel is commonly used in aerospace applications, as well as in high-performance automotive components. It is important to note that within each type of stainless steel strip alloy, there are numerous grades and variations available, each with its own specific properties and applications. Therefore, it is crucial to carefully select the appropriate alloy based on the requirements of the intended application.

- Q: Are stainless steel strips resistant to scaling and oxidation?

- Yes, stainless steel strips are resistant to scaling and oxidation. This is due to the high levels of chromium present in stainless steel, which forms a protective layer on the surface of the material. This layer, known as a passive film, prevents the steel from reacting with oxygen in the air and helps to prevent corrosion and scaling. Additionally, stainless steel also contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to oxidation and scaling. Therefore, stainless steel strips are widely used in various industries where corrosion resistance is crucial, such as in the manufacturing of kitchen appliances, automotive parts, and chemical processing equipment.

Send your message to us

Stainless Steel Coil Price in Wuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords