Stainless Steel Coil Price in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

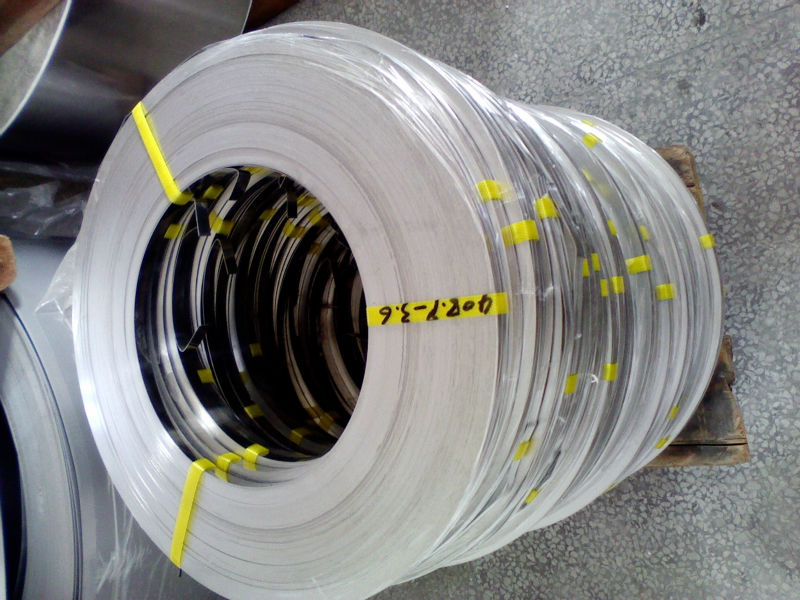

1.Product name:stainless steel Coil

2. Standard: ASTM,AISI,SUS,JIS,EN,DIN,BS,GB

3. Material:201,202,301,303,304,304L,305,316,316L,321,410,416,420,430 etc

4.Width:1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet),1800mm,2200mm or we can also help the size as you require

5.Thickness: From 0.25mm to 4mm

6. Surface:NO.1, NO.2D, NO.2B, BA,NO.3, NO.4,NO.240,NO.400,Hairline,NO.8, Brushed,

7. Application:Stainless steel sheet applies to construction field, ships building

industry, petroleum & chemical industries, war and electricity

industries, food processing and medical industry, boiler heatexchanger,

machinery and hardware fields. Stainless steel sheet can be made

accordingto the customers requirements

8.Minimum order qu antity: 10 TONS

Packaging & Shipping

Packaging Detail: Standard seaworthy package(wooden boxes package,pvc package, and other package)

- Q: Can stainless steel strips be used in kitchen appliances?

- Yes, stainless steel strips can be used in kitchen appliances. Stainless steel is a popular choice for kitchen appliances due to its durability, resistance to corrosion, and easy maintenance. Stainless steel strips can be used in a variety of kitchen appliances such as refrigerators, dishwashers, ovens, and range hoods. They provide a sleek and modern look to the appliances and are also easy to clean, making them a practical choice for the kitchen environment. Additionally, stainless steel is a hygienic material as it is non-porous and does not harbor bacteria or germs, making it suitable for use in food preparation areas. Overall, stainless steel strips are a versatile and reliable option for kitchen appliances.

- Q: Can stainless steel strips be used in the production of architectural fittings?

- Certainly, architectural fittings can indeed be produced using stainless steel strips. In the architectural industry, stainless steel is widely favored for its enduring quality, ability to resist corrosion, and captivating visual allure. With the aid of stainless steel strips, a diverse array of architectural fittings such as handrails, door handles, balustrades, and decorative elements can be effortlessly fashioned, welded, and fabricated. The flexibility of stainless steel enables the realization of both contemporary and classic architectural designs. Moreover, stainless steel's low maintenance nature renders it perfectly suited for architectural fittings that necessitate enduring durability in diverse environmental conditions.

- Q: Are stainless steel strips suitable for cryogenic storage?

- Stainless steel strips are indeed suitable for cryogenic storage due to their excellent strength, durability, and corrosion resistance. This material is highly favored for cryogenic applications due to its ability to withstand extremely low temperatures, typically below -150 degrees Celsius (-238 degrees Fahrenheit), without compromising its structural integrity. Moreover, stainless steel's low thermal conductivity aids in reducing heat transfer and maintaining the desired temperature within the cryogenic storage system. Therefore, selecting the right grade of stainless steel is crucial to ensure it meets the necessary specifications and can endure the specific conditions of the application.

- Q: Can stainless steel strips be used for structural applications?

- Yes, stainless steel strips can be used for structural applications. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for various structural projects such as building frames, bridges, and support structures.

- Q: Can stainless steel strips be used in aerospace manufacturing?

- Yes, stainless steel strips can be used in aerospace manufacturing. Stainless steel is a preferred material in the aerospace industry due to its high strength, corrosion resistance, and heat resistance properties. It is commonly used in various aircraft components such as frames, fasteners, and structural parts.

- Q: What are the standard dimensions for stainless steel strips?

- Different applications and industry requirements can cause variations in the standard dimensions of stainless steel strips. Nevertheless, typical dimensions encompass thicknesses ranging from 0.1mm to 3.0mm, widths spanning 10mm to 600mm, and lengths extending from 1000mm to 6000mm. These dimensions find frequent usage across diverse sectors including automotive, construction, and manufacturing. It is crucial to acknowledge that customization of these dimensions can occur to suit the particular demands of a project or application.

- Q: Can stainless steel strips be used in telecommunications equipment?

- Yes, stainless steel strips can be used in telecommunications equipment. Stainless steel's excellent strength, durability, and corrosion resistance make it suitable for various components and structures in telecommunications equipment, such as antenna mounts, connectors, enclosures, and cable trays. Additionally, stainless steel's electrical conductivity properties also make it suitable for certain applications in telecommunications equipment.

- Q: What are the common uses of stainless steel strips in the electronics industry?

- Due to their exceptional properties and versatility, stainless steel strips find various applications in the electronics industry. One of these is their use as shielding material to minimize electromagnetic interference. This interference can have a negative impact on the performance of electronic devices, which is why stainless steel strips are utilized for their excellent electromagnetic shielding properties. They effectively prevent the leakage or absorption of electromagnetic radiation, ensuring the smooth functioning of electronic components. In addition, stainless steel strips are commonly employed as connectors in the electronics industry. Due to their high electrical conductivity and corrosion resistance, they make reliable connector pins or terminals. This allows for efficient transmission of electrical signals and ensures a durable connection between different electronic components. Furthermore, stainless steel strips are utilized in the production of springs and contacts for various electronic devices. Their exceptional elasticity and resilience make them suitable for applications where electrical contacts need to be maintained under pressure. Stainless steel strips can withstand repeated bending and stretching without losing their shape or functionality. This makes them an ideal choice for use in switches, relays, and other electronic components. Moreover, stainless steel strips are also used in the manufacturing of battery contacts. These contacts require corrosion resistance and excellent electrical conductivity to ensure the proper functioning of the battery. Stainless steel strips fulfill these requirements, providing a reliable current flow and preventing any potential damage or degradation caused by corrosion. In summary, the wide range of uses for stainless steel strips in the electronics industry includes their use as shielding material, connectors, springs, contacts, and battery contacts. Their exceptional properties, such as corrosion resistance, electrical conductivity, and elasticity, make them an ideal choice for various electronic applications.

- Q: Can stainless steel strips be used in the automotive exhaust system?

- Indeed, the utilization of stainless steel strips is possible within the automotive exhaust system. Given its exceptional resistance to corrosion, high temperature strength, and durability, stainless steel stands as a favored material for exhaust systems. Utilizing stainless steel strips, one can fashion an array of exhaust system components, such as pipes, mufflers, and catalytic converters. These strips are capable of withstanding the harsh conditions inherent in the exhaust system, including elevated temperatures, moisture exposure, and the presence of corrosive gases. Moreover, stainless steel provides commendable aesthetics and can be effortlessly formed and welded, thus rendering it a versatile material for automotive exhaust systems.

- Q: Can 111 stainless steel strips be coated with anti-galling coatings?

- Yes, 111 stainless steel strips can be coated with anti-galling coatings.

Send your message to us

Stainless Steel Coil Price in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords