Steel Strip Coils in Various Materials from China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 1222665 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

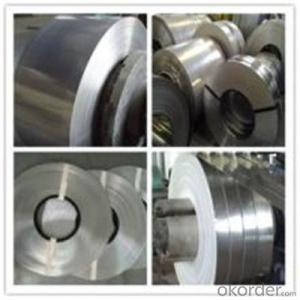

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1.Thickness: 0.14-3.0mm

2.width:30-600mm

3.zinc coating: 30-275g

4.material:Q195, Q235,SGCC, A653 CS-B, DX51D,SGCD,SGHC,S350GD,S450GD,S550GD

5.spangle: zero spangle, regular spangle, small spangle

Specifications of Steel Strip Coils:

1)Material:SPCC,SPHC,Q195,Q235,Q345,Q345B

2)Thick:0.15-3.0mm

3)Width:30-700mm

4)Zinc coating:Z6 to Z27(60g/m2 to 275g/m2, double sides)

5)Surface condition:Regular spangle

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips welded together to form larger structures?

- Steel strips are welded together to form larger structures using various welding techniques such as arc welding, MIG welding, or TIG welding. These techniques involve melting the edges of the steel strips and fusing them together using heat and pressure. The welds create a strong and durable bond, allowing the steel strips to be assembled into larger structures such as beams, frames, or even entire buildings.

- Q: Can steel strips be coated with protective coatings?

- Yes, steel strips can be coated with protective coatings. Coating steel strips with protective coatings is a common practice in various industries to enhance their durability, resistance to corrosion, and overall performance. There are several types of protective coatings available for steel, including but not limited to, galvanized coatings, powder coatings, epoxy coatings, and paint coatings. Galvanized coatings, for example, involve applying a layer of zinc to the steel strip through a process known as hot-dip galvanizing. This coating provides excellent corrosion resistance and protects the steel from environmental factors such as moisture and chemicals. Powder coatings are another popular option for protecting steel strips. In this process, a dry powder is applied to the steel strip electrostatically, and then it is cured under heat to create a durable and tough coating. Powder coatings offer excellent adhesion and resistance to abrasion, impact, and chemicals. Epoxy coatings, on the other hand, are commonly used to protect steel strips in harsh environments. These coatings are highly resistant to chemicals, moisture, and extreme temperatures. They provide an additional layer of protection to the steel, preventing corrosion and extending its lifespan. Paint coatings are also widely used to protect steel strips. These coatings can be applied by various methods such as spraying, brushing, or dipping. Paint coatings offer flexibility in terms of color options and can provide a decorative finish in addition to protecting the steel strip from corrosion and other damaging factors. In conclusion, steel strips can indeed be coated with various protective coatings to enhance their performance and longevity. The choice of coating will depend on the specific requirements of the steel strip and the environment it will be exposed to.

- Q: What are the different methods for grinding steel strips?

- Grinding steel strips can be accomplished using various methods, depending on the desired results and project specifications. Here are some commonly employed techniques: 1. Surface grinding entails utilizing a horizontal rotary table machine with a grinding wheel to eliminate material from the steel strip's surface. This approach is ideal for achieving a smooth and flat surface finish. 2. Blanchard grinding, a variation of surface grinding, utilizes a vertical spindle machine with a rotating magnetic chuck to remove material. It is particularly effective for grinding large steel strips or parts with high stock removal rates. 3. Centerless grinding involves feeding the steel strip between two grinding wheels, one stationary and the other rotating. This method is often used for grinding cylindrical steel strips with a consistent diameter. 4. Belt grinding employs a sanding belt embedded with abrasive particles to remove material from the steel strip. It is commonly used for deburring, polishing, and shaping the edges of steel strips. 5. Precision grinding relies on specialized grinding machines and techniques to achieve extremely tight tolerances and precise dimensions. This method is preferred for high-precision applications where accuracy is of utmost importance. 6. Cylindrical grinding entails using a cylindrical grinder to grind the outer surface of the steel strip. This method is commonly used for producing cylindrical steel strips with specific diameters or achieving desired surface finishes. These examples represent a small sample of the various grinding methods available for steel strips. The selection of a suitable approach depends on factors such as desired outcomes, project specifications, and the type of steel being processed. It is crucial to carefully consider these factors and consult with professionals before choosing a grinding method.

- Q: Are steel strips resistant to fire or heat?

- Yes, steel strips are generally resistant to fire and heat. Steel has a high melting point and does not ignite or burn easily, making it a suitable material for applications that involve exposure to high temperatures. However, it is important to note that extreme heat can cause steel to weaken and lose its structural integrity over time.

- Q: Are steel strips used in the production of metal brackets and supports?

- Yes, steel strips are commonly used in the production of metal brackets and supports. Steel strips provide strength, durability, and stability to these components. They are often used in applications where high load-bearing capacity is required. Steel strips can be easily shaped, cut, and welded, making them suitable for various bracket and support designs. Additionally, steel strips have excellent resistance to corrosion, making them ideal for outdoor or harsh environment applications.

- Q: What are the safety precautions when handling steel strips?

- When handling steel strips, it is important to follow several safety precautions. Firstly, always wear appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against cuts, impacts, and flying debris. Secondly, ensure that the work area is well-lit and free from clutter or obstructions to prevent accidents. When lifting or moving steel strips, use proper lifting techniques and equipment like cranes, forklifts, or lifting straps to avoid strain or injury. Additionally, be aware of the sharp edges and weight of the steel strips and handle them with care to prevent cuts or crushing injuries. Finally, store steel strips in a secure manner to prevent them from falling or causing hazards.

- Q: What are the common standards and specifications for steel strips?

- The most common standards and specifications for steel strips include the American Society for Testing and Materials (ASTM) standards, such as ASTM A109, ASTM A568, and ASTM A1011/A1011M. Additionally, the International Organization for Standardization (ISO) sets standards like ISO 3574 and ISO 9445 for steel strip manufacturing. These standards define the dimensions, mechanical properties, chemical composition, and tolerances required for steel strips used in various industries, ensuring consistency and quality across different manufacturers.

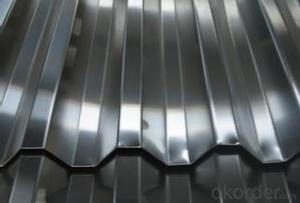

- Q: Can steel strips be used for making architectural panels?

- Yes, steel strips can definitely be used for making architectural panels. Steel is a versatile and durable material that is well-suited for architectural applications. Steel strips can be cut and shaped into various sizes and forms, making them ideal for creating architectural panels with different designs and patterns. Additionally, steel panels offer several advantages such as strength, fire resistance, and low maintenance, making them a popular choice for architectural projects. They can be used in a wide range of applications including exterior cladding, interior wall panels, roofing systems, and decorative features. The steel panels can also be treated with various finishes and coatings to enhance their aesthetic appeal and protect them from corrosion, further expanding their usability in architectural projects. Overall, steel strips provide a reliable and aesthetically pleasing option for creating architectural panels.

- Q: How do steel strips respond to different corrosion environments?

- Steel strips can respond differently to various corrosion environments depending on factors such as the type of corrosion, the composition of the steel, and the surrounding conditions. In general, steel strips are susceptible to corrosion, especially when exposed to moisture, oxygen, and aggressive chemicals. However, the response of steel strips to different corrosion environments can vary. In a dry environment with low humidity, steel strips are less likely to corrode significantly. They may develop a thin layer of surface rust, known as cosmetic or superficial corrosion, which does not affect the structural integrity of the steel. This can be easily removed through cleaning or light abrasive methods. In a humid environment, steel strips are more prone to corrosion. The presence of moisture in the air can lead to the formation of rust on the surface of the steel. This type of corrosion can progress over time, causing the steel strips to deteriorate, weaken, and eventually fail if not properly addressed. In marine or saltwater environments, steel strips are highly susceptible to corrosion due to the presence of chloride ions. Chloride ions can penetrate the protective oxide layer on the steel's surface and accelerate the corrosion process. This can lead to the formation of pitting corrosion, which can cause localized damage and weaken the steel strips. Certain chemicals and industrial atmospheres can also contribute to the corrosion of steel strips. Exposure to acids, alkaline substances, or corrosive gases can cause chemical corrosion, which can be highly destructive. The severity of the corrosion depends on factors such as concentration, temperature, and duration of exposure. To mitigate the effects of corrosion, various preventive measures can be taken. Coating the steel strips with protective layers, such as paint or galvanization, can provide a barrier against moisture and corrosive elements. Regular maintenance, including cleaning, inspection, and applying anti-corrosion treatments, can help prolong the lifespan of steel strips in different corrosion environments. Overall, the response of steel strips to different corrosion environments is influenced by multiple factors, and proper prevention and maintenance practices are essential to minimize the impact of corrosion and ensure the longevity of the steel strips.

- Q: How are steel strips used in the production of electrical conductors?

- Due to their exceptional electrical conductivity and mechanical properties, steel strips are commonly utilized in the manufacturing of electrical conductors. These strips act as the fundamental structure or core of the conductor, providing both strength and support. To enhance conductivity, steel strips are typically coated with a layer of copper or aluminum during the manufacturing process. This is accomplished using various techniques such as electroplating or hot dipping. The coating assists in reducing electrical resistance and enhancing the flow of electric current through the conductor. In the production of transformer windings, steel strips are also employed. Transformers are vital in the transmission and distribution of electricity, and the steel strip serves as the central component around which copper or aluminum wire is wound. The steel core ensures stability of the windings, preventing displacement and enabling proper insulation. Furthermore, steel strips find application in the production of overhead power lines. These power lines are responsible for carrying substantial amounts of electrical current over long distances, and steel strips are used as the core material for the conductors. By providing mechanical strength, the steel core prevents sagging of the power lines, ensuring efficient electricity transmission. In conclusion, steel strips are indispensable in the production of electrical conductors due to their electrical conductivity, mechanical strength, and ability to support and enhance conductor performance.

Send your message to us

Steel Strip Coils in Various Materials from China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 1222665 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords