316L STAINLESS STEEL COILMADE in WUXI GOOD QUALITY AND CHEAP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Description of the 316 stainless steel coil

316L stainless Steel adds Mo (2-3%), so it has excellent corrosion resistance and high temperature strength; SUS316L carbon content is lower than SUS316, therefore, the resistance to intergranular corrosion resistance is better than SUS316: high temperature creep strength is high. It can be used in harsh conditions.good strain hardening and non-magnetic.

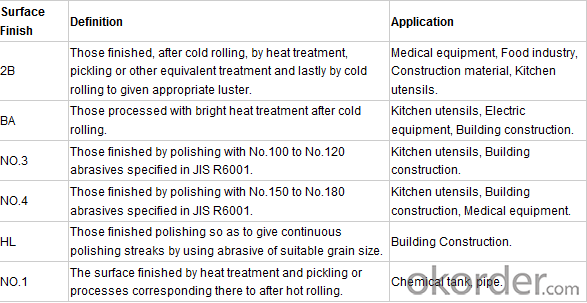

2,Applications of Stainless Steel Coils

3,related products show

4,Specification of the 316L stainless steel coil.

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

8. In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

9. We have complete after-sale service to deal with the problems in time.

5,FAQ

1,How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

2,How much is your daily output?

We can rate our daily output at about 200Ton-300Ton.

- Q: What is the composition of 111 stainless steel strips?

- The composition of 111 stainless steel strips typically refers to the specific alloy used to manufacture these strips. Stainless steel is an iron-based alloy that contains a minimum of 10.5% chromium. In addition to chromium, stainless steel may also contain other elements such as nickel, molybdenum, manganese, and carbon. The exact composition of 111 stainless steel strips can vary depending on the specific grade or specification. For example, a common grade is 304 stainless steel, which typically consists of 18% chromium and 8% nickel. Another commonly used grade is 316 stainless steel, which contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. To determine the precise composition of 111 stainless steel strips, it would be necessary to refer to the specific grade or specification provided by the manufacturer or supplier.

- Q: Can stainless steel strips be bent or formed?

- Yes, stainless steel strips can be bent or formed. Stainless steel has excellent formability and can be easily bent, shaped, or formed into various configurations without compromising its strength or structural integrity.

- Q: Are stainless steel strips suitable for elevator doors?

- Stainless steel strips, indeed, prove to be a fitting option for elevator doors. This durable and corrosion-resistant material finds extensive use in diverse applications, including elevator doors. Its robustness and ability to withstand wear make it a prime selection for elevator doors that experience frequent usage and constant interaction with passengers. Moreover, stainless steel possesses a sleek and contemporary look that elevates the overall aesthetics of the elevator, imparting a professional and sophisticated aura. All in all, stainless steel strips deliver the requisite durability, functionality, and visual allure demanded by elevator doors.

- Q: Can stainless steel strips be used in the pharmaceutical industry?

- Yes, stainless steel strips can be used in the pharmaceutical industry. Stainless steel is a popular material choice due to its high corrosion resistance, durability, and ability to withstand high temperatures and harsh chemicals. It is commonly used for manufacturing pharmaceutical equipment, storage tanks, and process piping to maintain hygienic conditions and prevent contamination in pharmaceutical processes.

- Q: How is corrosion resistance achieved in stainless steel strips?

- The ability of stainless steel strips to resist corrosion is achieved through a combination of factors inherent to their composition and structure. The main factor responsible for corrosion resistance is chromium. By adding significant amounts of chromium to the steel alloy (typically at least 10.5%), a thin oxide layer is formed on the surface of the steel. This layer acts as a barrier, preventing further corrosion and protecting the underlying steel from corrosive elements. In addition to chromium, stainless steel also contains other alloying elements like nickel, molybdenum, and nitrogen, which further enhance its corrosion resistance. These elements help stabilize the oxide layer and improve resistance to specific types of corrosion. The microstructure of stainless steel also plays a crucial role in its corrosion resistance. It can exist in different crystal structures, such as austenitic, ferritic, martensitic, and duplex. The most common type used in stainless steel strips is austenitic stainless steel, which has a face-centered cubic structure. This structure provides excellent corrosion resistance and makes stainless steel strips suitable for various applications. Moreover, stainless steel strips can undergo different surface treatments to enhance their corrosion resistance. These treatments include passivation, pickling, and electropolishing, which remove impurities, contaminants, and free iron from the surface, promoting the formation of a more robust and protective oxide layer. Overall, the combination of alloying elements, oxide layer formation, microstructure, and surface treatments contribute to the remarkable corrosion resistance of stainless steel strips. This makes them highly durable and suitable for various environments and applications where corrosion is a concern.

- Q: What is the maximum thickness available for stainless steel strips?

- The maximum thickness available for stainless steel strips can vary depending on the specific grade of stainless steel and the manufacturing capabilities of the supplier. However, in general, stainless steel strips can be produced in thicknesses ranging from 0.1 millimeters to several millimeters. Some suppliers may be able to provide even thicker strips upon request, but it is important to consult with the supplier to determine the maximum thickness available for the specific grade and requirements of the project.

- Q: How do you cut stainless steel strips?

- To cut stainless steel strips, there are a few methods you can use depending on the thickness and length of the strips. Here are a few common ways to cut stainless steel strips: 1. Manual cutting tools: For thinner stainless steel strips, you can use manual cutting tools such as tin snips or aviation snips. These tools have sharp blades that can easily cut through the stainless steel. However, keep in mind that they may not be suitable for thicker or larger strips. 2. Power shears: Power shears are handheld electric tools specifically designed for cutting metal sheets, including stainless steel. They provide a more precise and efficient cutting process compared to manual tools. Power shears are ideal for cutting stainless steel strips of various thicknesses. 3. Metal cutting bandsaw: If you are dealing with thicker or longer stainless steel strips, a metal cutting bandsaw is a great option. This machine uses a continuous loop blade with teeth designed for cutting through metal. It offers a smooth and accurate cut, making it suitable for industrial applications. 4. Plasma cutter: A plasma cutter is a high-powered tool that uses an electric arc and compressed air to cut through various metals, including stainless steel. It can handle thicker stainless steel strips and provides a clean and precise cut. However, plasma cutters are more expensive and require some level of expertise to operate safely. When cutting stainless steel strips, always ensure you are wearing appropriate protective gear, such as safety glasses and gloves. Additionally, make sure the stainless steel strip is securely clamped or held in place to prevent it from moving during the cutting process.

- Q: What are the different packaging options for stainless steel strips?

- There are several packaging options available for stainless steel strips, depending on the specific requirements and preferences of the customers. 1. Coil Packaging: Stainless steel strips can be packaged in coils, which are wound tightly and secured with straps or plastic wrap. Coils are an efficient packaging option as they allow for easy handling, transportation, and storage. They are suitable for large quantities of strips. 2. Wooden Crates: For added protection and durability, stainless steel strips can be packed in wooden crates. The strips are stacked neatly inside the crates and secured with straps or foam inserts to prevent any damage during shipping or storage. Wooden crates are commonly used for heavy-duty applications or when long-term storage is required. 3. Pallets: Stainless steel strips can also be packaged on pallets, where they are stacked and secured with bands or shrink wrap. This packaging option is convenient for easy handling using forklifts and ensures stability during transportation. Pallets are commonly used for smaller quantities of strips. 4. Bundles: Stainless steel strips can be bundled together using plastic or steel bands. This packaging option keeps the strips organized and secure, preventing any tangling or damage. Bundles are suitable for smaller quantities of strips and provide easy handling and storage. 5. Custom Packaging: Depending on the specific needs of the customer, stainless steel strips can be packaged in custom options. This may include adding protective covers, foam inserts, or custom labeling for easy identification. Custom packaging ensures that the strips are adequately protected and ready for use upon delivery. Overall, the packaging options for stainless steel strips vary based on factors such as quantity, transportation requirements, and desired level of protection. Manufacturers and suppliers work closely with customers to determine the most suitable packaging option to ensure the safe and efficient delivery of stainless steel strips.

- Q: Can stainless steel strips be used in the oil refining industry?

- Yes, stainless steel strips can be used in the oil refining industry. Stainless steel is known for its corrosion resistance, high temperature strength, and durability, making it a suitable material for various applications in this industry, including piping, storage tanks, heat exchangers, and other equipment that comes into contact with oil and its byproducts.

- Q: Can stainless steel strips be used in pulp and paper industries?

- The pulp and paper industries find stainless steel strips quite useful. Thanks to its remarkable corrosion resistance, stainless steel is an ideal material for industries that frequently encounter moisture or chemicals, like the pulp and paper industry. Multiple purposes can be served by stainless steel strips in this sector, including the production of paper machines and equipment, pulp screens, refining and washing systems, bleaching equipment, and paper handling systems. The durability and resistance to rust and corrosion of stainless steel allow the strips to endure the rigorous conditions and chemicals associated with pulp and paper processes, resulting in extended equipment lifespan and reduced maintenance expenses. Moreover, stainless steel is easy to clean and maintain, an essential aspect in preserving hygienic conditions necessary in the pulp and paper industry. Consequently, the excellent properties and suitability of stainless steel strips make them widely utilized in the pulp and paper industry.

Send your message to us

316L STAINLESS STEEL COILMADE in WUXI GOOD QUALITY AND CHEAP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords