Stainless Steel Coil Price inWuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304/310/316/430/202/201 stainless steel coil | ||

General Info | ||

Products: | Stainless Steel Coil | |

Grade: | 201/304/430/316/316L | |

Steel type: | Cold rolled or Hot rolled stainless steel | |

Thickness: | 0.3-12.0MM | |

standard size | 4'*8ft'(1219*2438mm), 4*10ft(1219*3048mm), 1000*2000mm,1500*3000 or customed size | |

Brand: | TISCO,JISCO,LISCO,BAO STEEL | |

Material Standard: | ASTM/JIS/GB/BV | |

Surface Protection: | Paper or PVC | |

Application: | Interior decoration, elveator, appliance… | |

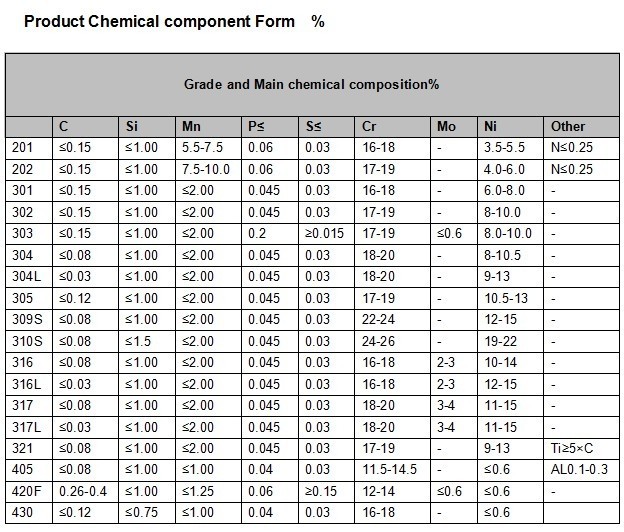

Chemical Composition

Core-competitiveness | ||

1. Leading Manufactures in the local market and exporting area | ||

2. Fast spead for the shipment with good quality and packing. | ||

3. One of the biggest stainless steel sheets stock holder in jiangsu province | ||

4.Flexible payment options such as:TT/ LC and Sale on credit for regular buyers |

Surface

| Definition | Application

|

No.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling.

| Chemical tank, pipe.

|

2B(No.2B) | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster.

| Medical equipment, Food industry, Construction material, Kitchen utensils.

|

NO.3

| Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001.

| Kitchen utensils, Building construction.

|

NO.4

| Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001.

| Kitchen utensils, Building construction, Medical equipment.

|

HL

| Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

BA(No.6) | Those processed with bright heat treatment after cold rolling.

| Kitchen utensils, Electric equipment, Building construction.

|

Mirror(No.8) | shinning like a mirror | Building construction decoration |

Packaging & Shipping

We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection.

Factory & Warehouse

- Q: Can stainless steel strips be used in chemical processing?

- Indeed, chemical processing can incorporate stainless steel strips. Renowned for its impressive resistance to corrosion, stainless steel proves to be an ideal material for a multitude of applications within the chemical industry. With its ability to withstand a wide range of aggressive chemicals, acids, and bases, as well as its capacity to endure high temperatures and pressures, stainless steel emerges as a commonly utilized component in chemical processing machinery, including reactors, heat exchangers, storage tanks, and piping systems. Offering durability, dependability, and an extensive lifespan, stainless steel strips are the favored choice for handling corrosive chemicals and upholding product purity during chemical processing operations.

- Q: What are the different types of edges available for stainless steel strips?

- The desired appearance and specific application determine the available types of edges for stainless steel strips. Examples of common edge types include: 1. Mill Edge: This straight and smooth finish is the standard produced during manufacturing, with no further processing or treatment. 2. Slit Edge: Achieved by cutting the strip to the desired width using a slitting machine, this edge may have a slight burr or roughness that can be eliminated through deburring or other finishing methods. 3. Rounded Edge: Also called a round or rolled edge, it involves rolling the strip to create a curved or rounded profile. This type of edge provides a safer and more comfortable surface, suitable for applications where sharp edges may be hazardous. 4. Deburred Edge: By removing burrs or roughness from the strip's edge, a smooth and clean finish is achieved. Deburring is typically done using specialized equipment or processes. 5. Beveled Edge: This edge is created by cutting the strip at an angle, usually 45 degrees, resulting in a sloping or chamfered edge. Beveled edges are often used for aesthetic purposes or to facilitate welding or joining of the strips. 6. Custom Edges: Custom edges can also be created to meet specific functional or aesthetic requirements of a project or application. These may include different profiles, finishes, or treatments. When selecting the appropriate edge type, it is crucial to consider the intended use and requirements of the stainless steel strips. The edge choice can impact the final product's performance, appearance, and safety.

- Q: What are the standard dimensions of stainless steel strips?

- The standard dimensions of stainless steel strips can vary depending on the manufacturer and specific application. However, common dimensions for stainless steel strips range from 0.1mm to 6mm in thickness and 10mm to 600mm in width.

- Q: Stainless steel strap easy to scrape, how to deal with?

- They use sandpaper to repair scratches watchcase watchband above, is not difficult, as long as careful steady hand could do; but for the surface polishing process, it must use the polishing machine, ordinary people can not do.

- Q: Can stainless steel strips be used in the production of oil and gas pipelines?

- Yes, stainless steel strips can be used in the production of oil and gas pipelines. Stainless steel is highly resistant to corrosion and can withstand extreme temperatures and pressures, making it a suitable material for pipelines in the oil and gas industry.

- Q: What are the advantages of using precision rolled 111 stainless steel strips?

- Precision rolled 111 stainless steel strips offer several advantages. Firstly, they provide uniform and reliable products due to the precision rolling process, which ensures consistent thickness and width. This is especially important in industries like electronics and precision instruments that require precise measurements. Secondly, 111 stainless steel is highly resistant to corrosion, making it ideal for applications exposed to harsh environments, chemicals, or moisture. The corrosion resistance extends the lifespan of the strips, reducing the need for frequent replacements and maintenance. Additionally, these strips have a high strength-to-weight ratio, offering exceptional strength despite being lightweight. This makes them suitable for industries like aerospace, automotive, and construction, where weight reduction is crucial for fuel efficiency and structural integrity. Moreover, precision rolled 111 stainless steel strips are easily shaped and molded, allowing for versatility in various applications. Whether for decorative purposes or functional components, these strips can be bent, stamped, or formed to meet specific design requirements. Lastly, these strips have an aesthetic appeal with a smooth surface finish and lustrous appearance. This makes them highly desirable for decorative applications like architectural accents, jewelry, or kitchenware. The strips can be polished or brushed to achieve different finishes, offering flexibility in design options. In conclusion, the advantages of precision rolled 111 stainless steel strips include consistent thickness and width, excellent corrosion resistance, high strength-to-weight ratio, exceptional formability, and aesthetic appeal. These qualities make them a popular choice in diverse industries, ensuring reliable performance and longevity for their intended applications.

- Q: Can stainless steel strips be used in watchmaking?

- Yes, stainless steel strips can be used in watchmaking. Stainless steel is commonly used in watchmaking due to its durability, corrosion resistance, and aesthetic appeal. It is often used for watch cases, bands, and other components.

- Q: Are stainless steel strips resistant to nitric acid corrosion?

- Yes, stainless steel strips are resistant to nitric acid corrosion.

- Q: Can stainless steel strips be used in the aerospace engine components?

- Aerospace engine components can indeed utilize stainless steel strips. Stainless steel is renowned for its impressive strength, durability, and ability to withstand corrosion, making it ideal for various applications in the aerospace sector. When it comes to engine components, specifically turbine blades, stainless steel strips are employed for their exceptional heat resistance and mechanical properties. These strips are capable of enduring high temperatures and pressures, ensuring reliable performance even in extreme conditions. Furthermore, they offer excellent fatigue resistance, which is vital for components that regularly experience stress and strain cycles within the engine. In conclusion, the incorporation of stainless steel strips in aerospace engine components can enhance the efficiency, safety, and lifespan of aircraft engines.

- Q: Are stainless steel strips suitable for kitchen appliances?

- Yes, stainless steel strips are suitable for kitchen appliances. Stainless steel is a popular choice for kitchen appliances due to its durability, resistance to corrosion, and sleek appearance. Stainless steel strips can be used for various applications in the kitchen, such as covering the front of appliances or as trim pieces. They provide a modern and polished look, while also being easy to clean and maintain. Additionally, stainless steel is resistant to stains and smudges, making it a practical choice for kitchen appliances that are exposed to constant use and handling. Overall, stainless steel strips are a great option for enhancing the aesthetics and functionality of kitchen appliances.

Send your message to us

Stainless Steel Coil Price inWuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords