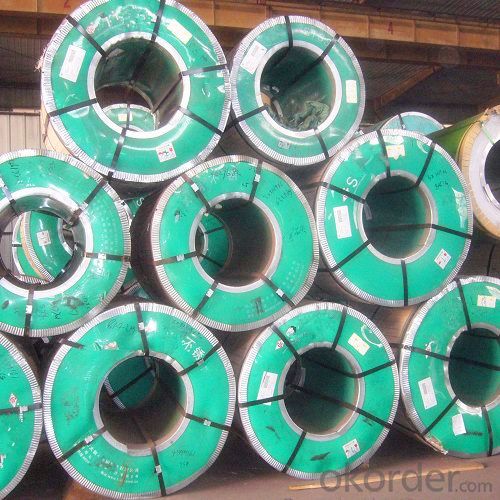

Hot Rolled Stainless Steel Coil 430 No.1 Finish

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade: | 400 Series | Standard: | JIS,AISI,ASTM,GB,DIN,EN | Length: | Coil |

Thickness: | 2.5mm,3.0mm, 4.0mm | Width: | 1000mm, 1219mm, 1240mm, 1500mm | Place of Origin: | China Mainland |

Brand Name: | CNBM | Model Number: | 430 | Type: | Coil |

Application: | Element Supports,Stove trim rings,Fasteners,Chimney Liners | Certification: | ISO | Certificate: | ISO9001:2008 |

Surface: | No.1 | Technique: | Hot Rolled | Experience: | About 20 years |

Stock Information: | In stock | Weight per coil: | 18-22 tons | Tolerance: | +/-0.1mm or less |

Model No.: | 430 |

|

|

|

|

Hot Rolled Stainless Steel Coil 430 No.1 Finish

Article | Hot Rolled Stainless Steel Coil 430R |

Grade | 400 series |

Specification | 1m, 1.2m, 1.5m |

Surface | No.1 |

Type | Sheet / Coil |

Width | 1000mm, 1219mm, 1240mm, 1500mm |

Thickness | 2.5mm,3.0mm, 4.0mm |

Brand name | CNBM |

Parking | seaworthy wooden pallets or wooden cases,in 20' or 40' container or as per customers' requirements |

Payment | 30% in advance,70% after shipping, or L/C at sight |

Delivery Time | Stock materials, within7-15 days after received the deposit of T/T or L/C |

Hot Rolled Stainless Steel Coil 430 No.1 Finish

Grade | C | Cr | Si | Mn | Mo | Ni | P | S |

| Max |

| Max | Max |

| Max | Max | Max |

430 | 0.12 | 16.0-18.0 | 0.75 | 1.00 | ----- | 0.6 | 0.04 | 0.03 |

- Q: Can stainless steel strips be bent or formed into complex shapes?

- Yes, stainless steel strips can be bent or formed into complex shapes due to their high strength and malleability. This characteristic allows for various fabrication processes, such as rolling, bending, and shaping, to achieve intricate and complex designs.

- Q: What are the common length tolerances for stainless steel strips?

- The common length tolerances for stainless steel strips can vary depending on the specific industry and application requirements. However, in general, the length tolerances for stainless steel strips typically range from +/- 0.005 inches to +/- 0.030 inches. These tolerances ensure that the stainless steel strips are cut and measured within the specified dimensions, allowing for a precise fit and optimal performance in various applications. It is essential to consult the specific industry standards and customer specifications to determine the exact length tolerances required for stainless steel strips in a particular application.

- Q: Are stainless steel strips resistant to hydrogen sulfide corrosion?

- Generally, stainless steel strips are resistant to hydrogen sulfide corrosion. They possess excellent corrosion resistance properties, especially against the corrosive effects of hydrogen sulfide gas. The presence of chromium in stainless steel creates a protective oxide layer on the surface, which acts as a barrier against corrosion. Moreover, stainless steel grades containing higher amounts of molybdenum, such as 316 and 904L, exhibit even greater resistance to hydrogen sulfide corrosion. However, it is important to acknowledge that the corrosion resistance of stainless steel strips can vary depending on the specific grade and environmental conditions. Therefore, seeking advice from a materials engineer or corrosion specialist is recommended to determine the most suitable stainless steel grade for a specific application involving exposure to hydrogen sulfide.

- Q: Are 111 stainless steel strips suitable for automotive exhaust systems?

- Automotive exhaust systems can benefit from the use of 111 stainless steel strips. This type of stainless steel, also known as AISI 111, is highly resistant to heat, corrosion, and rust, making it a popular choice for exhaust systems. Its excellent ductility, strength, and weldability make it a suitable material for this application. It can withstand extreme temperatures and harsh conditions, ensuring long-lasting performance and durability. In addition, stainless steel strips are easily shaped and formed, allowing for precise fabrication and customization according to the specific requirements of the exhaust system design. Overall, 111 stainless steel strips possess the necessary properties and characteristics to fulfill the demands of automotive exhaust systems.

- Q: How do you prevent rust on stainless steel strips?

- To prevent rust on stainless steel strips, it is essential to keep them clean and dry. Regular cleaning with mild soap and water helps remove any dirt or contaminants that may cause corrosion. Additionally, avoiding exposure to harsh chemicals, acids, or chloride-containing compounds can help protect the stainless steel from rusting. Applying a protective coating or using a rust inhibitor can also be effective in preventing rust formation on stainless steel strips.

- Q: Can 111 stainless steel strips be formed into wire for various applications?

- Absolutely! It is entirely possible to convert 111 stainless steel strips into wire, which can serve multiple purposes. Stainless steel is renowned for its remarkable ability to be molded and stretched, hence making it highly suitable for wire manufacturing. By undergoing a sequence of manufacturing methods like drawing, annealing, and cold rolling, these strips can be seamlessly transformed into wire. Consequently, the resultant stainless steel wire can be effectively utilized in an extensive array of applications encompassing electrical wiring, springs, fasteners, welding electrodes, and mesh.

- Q: Can stainless steel strips be bent or shaped?

- Stainless steel strips possess the ability to be bent or shaped. This type of material is known for its high malleability, enabling it to be effortlessly transformed into different forms and configurations. By utilizing the appropriate tools and techniques, stainless steel strips can be flexed, curved, or molded into the desired shape. The bending or shaping process typically entails the utilization of specialized machinery such as press brakes, rollers, or mandrels, which exert force on the stainless steel strip to achieve the intended configuration. Moreover, the thickness and tempering of the stainless steel strip play a role in determining its flexibility and ability to assume different shapes. All in all, stainless steel strips offer a remarkable level of versatility and can be easily manipulated to suit various applications and designs.

- Q: How do stainless steel strips perform in corrosive marine environments?

- Stainless steel strips possess a high resistance to corrosion and exhibit exceptional performance in corrosive marine settings. Their unique composition, consisting of chromium, nickel, and other alloying elements, enables the formation of a protective oxide layer on the surface. This layer acts as a barrier, effectively shielding the strips from corrosive elements like saltwater, moisture, and atmospheric conditions encountered in marine environments. The corrosion-resistant nature of stainless steel strips makes them highly suitable for various marine applications, including boat fittings, marine hardware, offshore platforms, and underwater structures. They are capable of enduring the harsh conditions of saltwater, waves, and high humidity without compromising their structural integrity or aesthetic appeal. Moreover, stainless steel strips offer excellent resistance against pitting and crevice corrosion, which are prevalent forms of corrosion in marine settings. This characteristic ensures their long-term durability and reliability, even in highly corrosive conditions. In addition, stainless steel strips are easy to clean and maintain as they do not require any additional coatings or treatments to protect against corrosion. Regular cleaning with fresh water is typically sufficient to maintain their excellent condition. In conclusion, stainless steel strips are an ideal choice for corrosive marine environments due to their exceptional resistance to corrosion, strength, and durability. They provide a cost-effective and reliable solution that can withstand the challenges posed by the marine environment, ensuring long-lasting performance.

- Q: What are the dimensions of stainless steel strips?

- The dimensions of stainless steel strips can vary depending on the specific needs and requirements of the application. However, stainless steel strips are commonly available in various thicknesses ranging from 0.1mm to 6mm and widths ranging from 10mm to 2000mm. The length of stainless steel strips can also vary, but it is typically available in coils or rolls of standard lengths, such as 1000mm or 2000mm. Additionally, stainless steel strips can be custom-cut to specific dimensions to suit individual project requirements.

- Q: Can stainless steel strips be used for electrical enclosures?

- Yes, stainless steel strips can be used for electrical enclosures. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for protecting electrical components from external elements and providing long-term reliability.

Send your message to us

Hot Rolled Stainless Steel Coil 430 No.1 Finish

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords