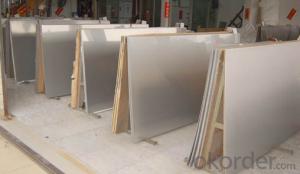

Stainless Steel 304 sheet from China top manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: How do you prevent clogging in stainless steel pipes?

- To prevent clogging in stainless steel pipes, there are several measures that can be taken: 1. Regular maintenance: It is important to perform regular maintenance on stainless steel pipes to prevent clogging. This includes periodic inspection and cleaning to remove any build-up or debris that may lead to blockages. 2. Proper disposal of waste: Ensure that only appropriate materials are disposed of in the pipes. Avoid flushing or introducing items such as paper towels, sanitary products, or grease down the drain, as these can accumulate and cause clogs. 3. Use drain filters: Install drain filters or strainers at the openings of the pipes to catch any large particles or debris that could potentially cause clogs. These filters can be cleaned regularly or replaced as needed. 4. Avoid corrosive materials: Some chemicals or substances can corrode stainless steel pipes, leading to damage and potential clogs. It is important to avoid using corrosive materials in or near the pipes and to follow manufacturer guidelines for chemical usage. 5. Proper water flow: Ensure that there is adequate water flow through the pipes to prevent clogging. This can be achieved by running water regularly, especially for pipes that are not frequently used. 6. Consider water softeners: If the water supply is particularly hard, it may contain minerals that can build up and eventually clog the pipes. Installing a water softener can help reduce mineral deposits and prevent clogs. 7. Seek professional help: If you experience persistent clogging or are unsure of how to prevent it, it is recommended to consult with a professional plumber. They can assess the situation, provide guidance on preventive measures, and address any existing clogs effectively. By following these preventive measures, you can minimize the risk of clogs in stainless steel pipes and ensure the smooth operation of your plumbing system.

- Q: What is the difference between 904L and 316 stainless steel pipes?

- 904L and 316 stainless steel are both commonly used materials for pipes in various industries. The main difference between these two grades lies in their composition, properties, and applications. 1. Composition: - 904L stainless steel contains high levels of chromium, nickel, and molybdenum, along with copper. It has a higher alloy content compared to 316 stainless steel. - 316 stainless steel, also known as marine grade stainless steel, contains significant amounts of chromium, nickel, and molybdenum. However, it lacks copper in its composition. 2. Corrosion Resistance: - 904L stainless steel is highly resistant to corrosion, especially in aggressive environments such as seawater and acidic conditions. Its high chromium, nickel, and molybdenum content provide superior protection against pitting and crevice corrosion. - 316 stainless steel also offers excellent corrosion resistance, particularly in marine and chloride-rich environments. However, it is not as resistant to corrosion as 904L stainless steel. 3. Strength and Durability: - 904L stainless steel exhibits higher strength and durability compared to 316 stainless steel due to its higher nickel and molybdenum content. It can withstand higher pressures and temperatures, making it suitable for applications in extreme conditions. - 316 stainless steel possesses good strength and durability but is slightly lower in comparison to 904L stainless steel. 4. Applications: - 904L stainless steel pipes are commonly used in industries such as petrochemical, chemical processing, oil and gas, and marine applications. They are ideal for environments with high chloride levels and acidic conditions. - 316 stainless steel pipes are widely used in various industries, including food processing, pharmaceuticals, architecture, and marine applications. They are suitable for general-purpose applications where corrosion resistance is required but not as critical as in aggressive environments. In summary, while both 904L and 316 stainless steel pipes offer corrosion resistance, 904L stainless steel provides superior performance in aggressive environments due to its higher alloy content. However, 316 stainless steel is more commonly used in general-purpose applications where a high level of corrosion resistance is not essential.

- Q: Can stainless steel pipes be passivated?

- Yes, stainless steel pipes can be passivated. Passivation is a process that removes contaminants from the surface of stainless steel and forms a protective oxide layer, enhancing its corrosion resistance. This process is commonly used in various industries to ensure the long-term durability and performance of stainless steel pipes.

- Q: What are the different types of stainless steel pipe fittings?

- Various piping systems commonly use several different types of stainless steel pipe fittings. Some of the most frequently used ones are: 1. Stainless Steel Elbows: These fittings alter the pipe's direction by either 90 degrees or 45 degrees. They come in various angles and sizes to accommodate the specific requirements of the piping system. 2. Stainless Steel Tees: Tees create a branch in the pipeline, enabling the fluid flow in multiple directions. They possess three openings, with one inlet and two outlets. 3. Stainless Steel Couplings: Couplings connect two pipes of the same diameter. They come in different variants, including full coupling (both ends are threaded), half coupling (only one end is threaded), and reducing coupling (for connecting pipes of different diameters). 4. Stainless Steel Reducers: Reducers join pipes of varying diameters. They are available in two types: concentric reducers (tapered on both ends) and eccentric reducers (tapered on one end only). 5. Stainless Steel Caps: Caps seal the end of a pipe and are commonly used when further extension of the pipe is unnecessary. 6. Stainless Steel Crosses: Crosses resemble tees but have four openings instead of three. They create a branch in the pipeline with multiple outlets. 7. Stainless Steel Unions: Unions connect two pipes without the need for threading. They offer a convenient way to disassemble and reassemble the pipes for maintenance or repairs. 8. Stainless Steel Nipples: Nipples are short pipe sections with male threaded ends. They extend a pipe or facilitate a connection between two female threaded fittings. It is important to note that these examples represent only a fraction of the diverse range of stainless steel pipe fittings available. The specific fitting required depends on factors such as the application, pipe size, and other considerations.

- Q: Can stainless steel pipes be used in nuclear power plants?

- Yes, stainless steel pipes can be used in nuclear power plants. Stainless steel is a commonly used material in the construction of nuclear power plants due to its high strength, corrosion resistance, and ability to withstand high temperatures. Stainless steel pipes are particularly suitable for carrying coolant, gases, and other fluids within the power plant. These pipes are able to handle the demanding conditions and requirements of a nuclear power plant, including the high pressure and high temperatures that are present in certain parts of the plant. Additionally, stainless steel is resistant to the corrosive effects of radiation, making it a reliable choice for use in nuclear power plants.

- Q: What is the difference between electropolished and bright annealed stainless steel pipes?

- Electropolished stainless steel pipes undergo a process called electropolishing, which involves the removal of surface impurities and oxidation through an electrochemical process. This results in a smooth, shiny, and corrosion-resistant surface finish. On the other hand, bright annealed stainless steel pipes are heat-treated to achieve a bright, reflective surface finish. While both processes enhance the aesthetics of the pipes, electropolishing provides additional benefits such as improved cleanability and increased resistance to corrosion.

- Q: Are stainless steel pipes resistant to UV radiation?

- UV radiation does not affect stainless steel pipes as they are resistant to it. Stainless steel is renowned for its exceptional ability to resist corrosion, including the harmful impacts of UV radiation. When exposed to UV radiation, stainless steel develops a passive oxide layer on its surface, which acts as a shield to prevent further harm. This oxide layer effectively prevents degradation, discoloration, and loss of mechanical properties that can arise from exposure to UV radiation. Consequently, stainless steel pipes are an ideal option for outdoor or exposed uses where UV radiation is a concern.

- Q: Can stainless steel pipes be used for chemical processing plants?

- Yes, stainless steel pipes can be used for chemical processing plants. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals and high temperatures often found in chemical processing plants. It also maintains its strength and durability over time, making it a suitable choice for transporting and storing various chemicals in such facilities.

- Q: How do stainless steel pipes compare to copper nickel pipes?

- Stainless steel pipes and copper nickel pipes have different properties and are suitable for different applications. Stainless steel pipes are highly resistant to corrosion, making them ideal for applications where exposure to moisture or chemicals is a concern. Copper nickel pipes, on the other hand, offer excellent resistance to seawater corrosion, making them commonly used in marine environments. Additionally, copper nickel pipes have superior thermal conductivity compared to stainless steel pipes. Ultimately, the choice between stainless steel and copper nickel pipes depends on the specific requirements and conditions of the intended application.

- Q: What kind of stainless steel square tube is used in ordinary square tubes?

- In the industry of stainless steel tube is mainly used to do some pipelines, of course in the construction industry and its use is more widely used, such as shutters, staircase handrails, railings, road partition and so on, at present, many products are used in stainless steel pipe, such as bicycles, medical equipment, automobile and so on.

Send your message to us

Stainless Steel 304 sheet from China top manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords