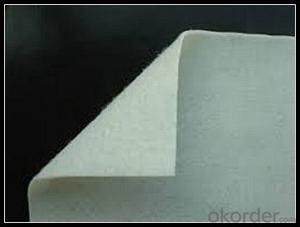

Agrafe Stabilization Non-Woven Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

NONWOVEN GEOTEXTILES

1 Civil

2 Environmental

3 Paving

Description

CMAX's civil nonwoven fabrics are produced using the latest technology in geotextile

manufacturing. Comprised of high strength polypropylene fiber, CMAX's complete line of

needle punched nonwovens provides superior performance in applications of filtration,

separation, drainage and erosion protection.

Benefits

Durable, chemical resistant UV stabilized polypropylene fibers

High tensile strength, with excellent puncture and tear resistance

NW structure provides excellent surface friction and built in elongation

Chemically stable for use in aggressive environments

Fine pore structure and high permittivity

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is geomembrane geomembrane, composite geomembrane

- What is geomembrane geomembrane, composite geomembrane

- Q: What are the specifications for geotextiles in railway projects?

- The specifications for geotextiles in railway projects typically include factors such as material type, weight, strength, permeability, and durability. These geotextiles are required to have high tensile strength and puncture resistance to withstand the heavy loads and dynamic forces exerted by train traffic. They should also possess appropriate permeability to allow for effective drainage and prevent water accumulation. Additionally, geotextiles used in railway projects should be chemically stable, resistant to degradation from UV exposure, and capable of withstanding various environmental conditions.

- Q: Are high geotextiles harmful to people?

- High-tech geotextile is not harmful to people. High-iron geotextile for strong, tensile, anti-friction coefficient, anti-oxidation time and other indicators are very strict, it can be said that geotextile applications so far the highest requirements. The raw materials for the production of geotextile are polypropylene fiber, polypropylene fiber civilian use: can be pure or wool, cotton or viscose blended mixed woven to produce a variety of clothing. Can be used for weaving all kinds of knitwear such as socks, gloves, sweaters, knitted pants, dish cloth, mosquito cloth, was expo, warm filler, diaper wet. Industrial use: geotextile, industrial filter cloth, carpet, fishing nets, canvas, hose, concrete reinforced materials, industrial fabrics, nonwovens and so on. So do not worry, high-speed rail geotextile with environmental requirements, no harm to the human body.

- Q: Do you need to cover the geotextile?

- Do not need, bathroom waterproof can choose a professional kitchen and toilet waterproof paste, or K11 waterproof slurry, water and electricity transformation, as long as the direct brushing on the base surface can be done until the waterproof layer can do 48 to 72 hours Of the closed water experiment, no problems can be posted after the brick.

- Q: Geotextile manufacturers are what industry

- Petrochemical! Raw materials are all extracted from the oil out of the glial particles!

- Q: Is there a coinage between the embedded pipeline and the gravel blind ditch? Also on the backfill plant how to set the quota? Also ask the master advise! More

- You can go to the civil online forum to ask questions, there are a little more professional.

- Q: Measured geotextile vertical permeability, "highway engineering geosynthetics test procedures" T1141-2006 6.3 balanced head difference is not necessary to balance the 50mm? Can not balance ah more

- So deep, although we produce geotextile, but geotextile detection really is not proficient in it

- Q: Where to find the right geotextile

- Geotextile types are many, according to the manufacturing process of spinning, woven, woven, according to the material is divided into filaments, short wire and so on, if the most suitable geotextile should be the project requirements are not very strict , Generally like building coverage, road maintenance, etc., like this price is generally around 0.5 angle

- Q: Are geotextiles suitable for use in geogrid reinforced soil slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced soil slopes. Geotextiles provide additional reinforcement and stability to the soil, enhancing the performance of geogrids in slope stabilization. They help in preventing soil erosion, reducing water infiltration, and improving overall slope stability.

- Q: Are geotextiles resistant to puncture?

- Yes, geotextiles are generally resistant to puncture due to their strong and durable construction.

Send your message to us

Agrafe Stabilization Non-Woven Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords