SS 904L Seamless Stainless Steel Pipe in Wuxi ,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

316 stainless steel pipe

Product Description

Name | Stainless Steel Seamless & Welded Tube &Pipe | |||||

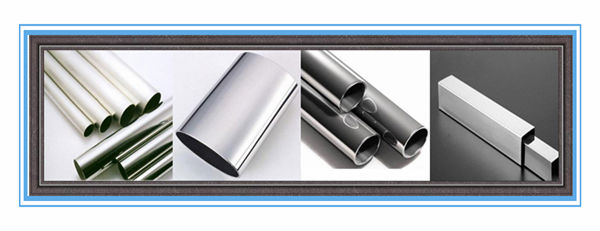

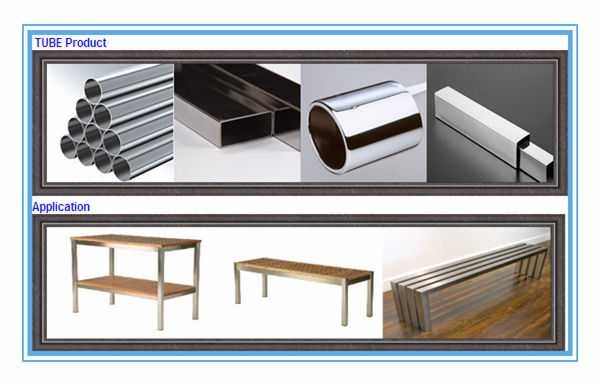

Items | Square tubes, round tubes, oval pipes, special shaped pipes, empaistic pipes, fittings | |||||

Standard | ASTM A554, A249, A269 and A270 | |||||

Material Grade | 201: Ni 0.8%~1% | |||||

202: Ni 3.5%~4.5% | ||||||

304: Ni 8%, Cr 18% | ||||||

316: Ni 10%, Cr 18% | ||||||

316L: Ni10%~14% | ||||||

430: Cr16%~18% | ||||||

Outer Diameter | 9.53mm--159mm | |||||

Thickness | 0.3mm - 3.0mm | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Outer Diameter: +/- 0.2mm | |||||

b) Thickness: +/- 0.02mm | ||||||

c) Length: +/- 5mm | ||||||

Surface | 180G, 240G, 320G Satin / Hairline 400G, 600G Mirror finish | |||||

Application | handrail,railing, staircase, weldmesh screen,door,window, balcony,fence,bench,furniture,etc | |||||

Test | Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT | |||||

Chemical Composition of Material | Material

Composition | 201 | 202 | 304 | 316L | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.035 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 13-15 | 14-17 | 18-20 | 16-18 | 16-18 | |

Ni | 0.7-1.1 | 3.5-4.5 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <105< span=""> | <100< span=""> | <90< span=""> | <90< span=""> | ||

Our Work shop

Our products:

Definition of stainless steel(Adopted form Wikipedia)

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable",

is defined as a steelalloy with a minimum of 10.5% to 11% chromium content by mass.

Stainless steel does not readily corrode, rust or stain with water as ordinary steel does,

but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity,

or poor circulation environments. It is also called corrosion-resistant steel or CRES

when the alloy type and grade are not detailed, particularly in the aviation industry.

There are different grades and surface finishes of stainless steel to suit the environment

the alloy must endure. Stainless steel is used where both the properties of steel

and resistance to corrosion are required.

- Q: What is the difference between hot rolled and cold drawn stainless steel pipes?

- The production of hot rolled stainless steel pipes involves heating a solid steel billet or ingot to a high temperature and then rolling it into the desired shape and size. This process yields a rougher surface finish and a larger grain structure, increasing the pipe's susceptibility to corrosion. Nevertheless, hot rolled pipes are generally more cost-effective and convenient for large-scale production. In contrast, cold drawn stainless steel pipes are crafted by pulling a solid steel billet or bar through a die at room temperature. This method results in a smoother surface finish and a smaller grain structure, enhancing the pipe's ability to resist corrosion. Cold drawn pipes are typically pricier and require more time and effort to manufacture, but they offer superior quality and performance for various applications. To summarize, the primary distinction between hot rolled and cold drawn stainless steel pipes lies in the manufacturing process and the resulting surface finish and grain structure. Hot rolled pipes are less expensive and easier to produce but may be more vulnerable to corrosion, whereas cold drawn pipes are more costly and time-consuming to manufacture but provide better corrosion resistance and overall quality.

- Q: Are stainless steel pipes suitable for high-pressure applications?

- Indeed, high-pressure applications find stainless steel pipes to be fitting. Recognized for their remarkable durability and ability to resist corrosion, stainless steel emerges as a material ideally suited for managing fluids or gases under high pressure. It maintains its shape and integrity even when subjected to high pressures, guaranteeing system safety and reliability by averting deformities or leaks. Furthermore, the smooth internal surface of stainless steel pipes reduces flow resistance and impedes the accumulation of debris or contaminants, thereby heightening their suitability for high-pressure applications.

- Q: What are the different types of stainless steel pipe hangers?

- There is a variety of stainless steel pipe hangers available, each designed for specific applications and needs. Some commonly used types include: 1. Split ring hangers: These hangers consist of a split ring that wraps around the pipe to provide support and stability. They are easy to install and adjust, making them suitable for pipes of different sizes. 2. Clevis hangers: Clevis hangers feature a U-shaped bracket that attaches to the pipe using a clevis pin. They have a high load-bearing capacity and are commonly used for vertical pipe installations. 3. Swivel ring hangers: Swivel ring hangers are designed to allow the pipe to move freely, accommodating thermal expansion and contraction. They have a circular ring that can rotate, reducing stress on the pipe. 4. Riser clamps: Riser clamps are used to support vertical pipes that run along walls or beams. They come in various designs and can be adjusted to fit different pipe sizes and configurations. 5. Beam clamps: Beam clamps are used to secure pipes to overhead beams or structures. They typically have a bolt or threaded rod that attaches the clamp to the beam, providing a secure mounting point. 6. Pipe rollers: Pipe rollers support pipes that need horizontal movement, such as sliding or rolling applications. They consist of rollers or wheels that allow the pipe to move smoothly. 7. Pipe straps: Pipe straps are simple and cost-effective hangers that wrap around the pipe and attach to a surface using screws or bolts. They are commonly used for light-duty applications or in limited space conditions. 8. Pipe saddles: Pipe saddles are used to support pipes that need to be raised or protected from direct contact with a surface. They usually have a curved or U-shaped design that cradles the pipe. It is important to choose the appropriate stainless steel pipe hanger based on specific installation requirements, including pipe size, load capacity, movement, and environmental factors. Seeking advice from a knowledgeable supplier or engineer can assist in choosing the right hanger for the job.

- Q: Can stainless steel pipes be magnetized?

- Yes, stainless steel pipes can be magnetized to some extent. However, unlike ferromagnetic materials such as iron or nickel, stainless steel is generally considered non-magnetic. This is because it contains a high level of chromium, which forms a protective oxide layer on the surface of the steel, preventing it from being easily magnetized. However, stainless steel can still be weakly attracted to a magnet, especially if it has undergone certain processes such as cold working or welding. In these cases, the crystalline structure of the steel may change, allowing it to become slightly magnetic. It's important to note that the magnetism in stainless steel pipes is relatively weak and will not hold or attract other magnetic objects as strongly as ferromagnetic materials would.

- Q: Can stainless steel pipes be used in the construction industry?

- Yes, stainless steel pipes can be used in the construction industry. They are highly durable, corrosion-resistant, and can withstand extreme temperatures, making them suitable for a wide range of applications such as plumbing, heating, ventilation, and structural support.

- Q: What are the limitations of using stainless steel pipes?

- The utilization of stainless steel pipes is associated with several limitations. To begin with, stainless steel pipes are inclined to be pricier in comparison to materials like PVC or copper. This aspect can render them less viable for projects with financial constraints. Moreover, the installation of stainless steel pipes can be more challenging and necessitate the use of specialized tools and equipment. Consequently, this can lead to an increase in both the overall installation time and cost. Another constraint is that stainless steel pipes are unsuitable for the transportation of certain corrosive chemicals or gases. There is a possibility of a chemical reaction occurring with certain substances, resulting in corrosion and potential harm to the pipes. In such scenarios, alternative materials such as plastic or lined pipes may be more suitable. Additionally, stainless steel pipes may possess limitations in terms of their resistance to temperature and pressure. Although they can withstand relatively high temperatures and pressures, extreme conditions may require the utilization of more robust materials. Furthermore, stainless steel pipes exhibit lower thermal conductivity compared to other materials, implying that they are not as efficient in transferring heat. This can be a limitation in certain heating or cooling applications that require rapid heat transfer. Lastly, stainless steel pipes are susceptible to expansion and contraction with changes in temperature. Consequently, the use of expansion joints or other measures may be necessary to accommodate these movements and avoid potential damage. In conclusion, although stainless steel pipes offer numerous advantages such as durability and resistance to corrosion, it is crucial to carefully consider their limitations before selecting them for a specific project.

- Q: Can stainless steel pipes be used for air pollution control systems?

- Yes, stainless steel pipes can be used for air pollution control systems. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for handling harsh environments and corrosive gases that are commonly found in air pollution control systems. Stainless steel pipes also have the advantage of being able to withstand high temperatures, allowing them to be used in applications where thermal resistance is required. Additionally, stainless steel is known for its hygiene properties, making it an ideal choice for industries that require clean and sterile air handling. Overall, stainless steel pipes are a popular and reliable choice for air pollution control systems due to their strength, durability, corrosion resistance, and ability to handle high temperatures.

- Q: What is the maximum diameter for a stainless steel pipe?

- The maximum diameter of a stainless steel pipe can differ based on different factors including the manufacturing process, grade of stainless steel, and intended use. Nevertheless, in general, stainless steel pipes can be produced in a diverse range of diameters to accommodate various industrial and commercial requirements. The maximum diameter can span from a few millimeters for precise, small pipes utilized in industries like medical and instrumentation, to several meters for extensive pipes used in applications like oil and gas pipelines or industrial infrastructure. It is advisable to seek guidance from a reliable manufacturer or supplier to ascertain the particular maximum diameter offered for the desired stainless steel pipe.

- Q: Are stainless steel pipes suitable for abrasive media?

- Indeed, abrasive media finds stainless steel pipes to be a fitting option. Renowned for its impressive strength and resistance to corrosion, stainless steel proves to be an ideal material for managing abrasive substances. The sleek surface of stainless steel pipes aids in diminishing friction and lessening the damage caused by abrasive particles. Moreover, stainless steel pipes exhibit the ability to endure elevated pressures and temperatures, rendering them suitable for diverse industrial functions encompassing abrasive media, such as mining, chemical processing, and wastewater treatment. In summary, stainless steel pipes stand as a dependable and enduring selection for the transportation of abrasive media.

- Q: How do you prevent pitting corrosion in stainless steel pipes?

- To prevent pitting corrosion in stainless steel pipes, several measures can be taken: 1. Choose the right grade of stainless steel: Not all stainless steels are created equal. Opt for grades with a higher resistance to corrosion, such as 316 or 904L, which contain molybdenum and have better resistance to pitting corrosion. 2. Adequate alloying elements: Ensure that the stainless steel pipe contains the proper amount of alloying elements, such as chromium and molybdenum. These elements form a protective layer on the surface of the steel, making it more resistant to corrosion. 3. Regular cleaning and maintenance: Regularly clean the stainless steel pipes to remove any contaminants or deposits that could lead to pitting corrosion. Avoid using abrasive materials or cleaners that may damage the protective layer of the steel. 4. Avoid exposure to aggressive environments: Limit the exposure of stainless steel pipes to aggressive substances like chloride ions, acidic solutions, or high temperatures, as these can accelerate pitting corrosion. If exposure is unavoidable, consider using protective coatings or linings to create a barrier between the steel and the corrosive environment. 5. Cathodic protection: Implement cathodic protection techniques, such as sacrificial anode systems or impressed current systems, to protect stainless steel pipes. These methods create a potential difference between the stainless steel and a more easily corroded metal, redirecting corrosion away from the stainless steel. 6. Control water chemistry: In applications involving water, monitor and control the water chemistry parameters such as pH, temperature, and chloride levels. Adjusting these factors within acceptable limits can help prevent pitting corrosion in stainless steel pipes. 7. Implement proper design and installation practices: Ensure that stainless steel pipes are designed and installed correctly, considering factors such as avoiding crevices, proper drainage, and avoiding stagnant areas where corrosion can occur. Proper insulation and the use of gaskets or flanges made from compatible materials can also prevent pitting corrosion. By following these preventive measures, you can significantly reduce the risk of pitting corrosion in stainless steel pipes, extending their lifespan and maintaining their structural integrity.

Send your message to us

SS 904L Seamless Stainless Steel Pipe in Wuxi ,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords