304 321 316 316l Stainless Steel Seamless Pipe in Wuxi ,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

C | Si | Mn | P | S | Ni | Cr | |

| SS304 | 0.046 | 0.316 | 1.481 | 0.0424 | 0.0028 | 8.001 | 18.019 |

| SS201 | 0.111 | 0.31 | 9.45 | 0.029 | 0.006 | 0.871 | 14.110 |

| SS316 | ≤0.08 | ≤1 | ≤2 | 0.035 | 0.03 | 1.0~14.0 | 16.0~18.5 |

Shape | Round / Square Etc. |

Brand | PEMCO/OEM/ODM |

Material | SS Stainless Steel 201, 304 , 316 |

Quality | First Grade |

Finish | Satin/Mirror |

Technology | Casting |

Certificate | ISO 9001-2000 |

Application | *Construction And Stair , Handrail , Railing Use |

*Shopping Mall,House,Outdoor | |

Feature | Beautiful Outlook, Easy To Clean, Low Maintenance Cost |

Usage | Widely Used On Stainless Steel Balustrade & Handrails, Indoor Or Outdoor Decorations,Etc. |

MOQ | 10 Pieces |

Delivery Time | 15-20 Days |

hot sale

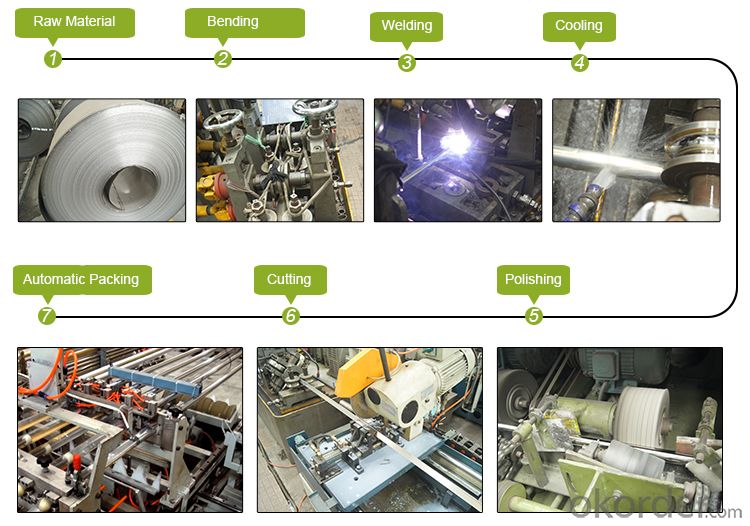

Production Process

Definition of stainless steel(Adopted form Wikipedia)

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable",

is defined as a steelalloy with a minimum of 10.5% to 11% chromium content by mass.

Stainless steel does not readily corrode, rust or stain with water as ordinary steel does,

but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity,

or poor circulation environments. It is also called corrosion-resistant steel or CRES

when the alloy type and grade are not detailed, particularly in the aviation industry.

There are different grades and surface finishes of stainless steel to suit the environment

the alloy must endure. Stainless steel is used where both the properties of steel

and resistance to corrosion are required.

Surface Finish :

Surface finish | Characteristics and application |

No.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties, No2B could nearly satisfy comprehensive uses. |

No.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

- Q: What is the difference between Schedule 20 and Schedule 40 stainless steel pipes?

- The main difference between Schedule 20 and Schedule 40 stainless steel pipes is their wall thickness. Schedule 20 pipes have a thinner wall compared to Schedule 40 pipes, making them lighter and more suitable for low-pressure applications. On the other hand, Schedule 40 pipes have a thicker wall, making them stronger and more suitable for high-pressure applications.

- Q: Can stainless steel pipes spray black paint?

- Can. The surface roughening with a thick gauze, do not use ordinary paint intensity difference. With resin paint, paint can be

- Q: Can stainless steel pipes be hydrotested?

- Yes, stainless steel pipes can be hydrotested. Hydrostatic testing is a common method used to check the integrity and strength of pipes. It involves filling the pipes with water or another suitable liquid and applying pressure to the pipes to check for leaks or failures. Stainless steel pipes are often used in various industries due to their corrosion resistance and durability. Therefore, they can undergo hydrotesting to ensure their reliability and performance. However, it is important to follow the appropriate safety guidelines and procedures while conducting hydrotesting on stainless steel pipes to prevent any potential damage or accidents.

- Q: How do you calculate the pipe length required for a specific application?

- To calculate the pipe length required for a specific application, you need to consider factors such as the flow rate, pressure drop, pipe material, and the type of fluid being transported. By using equations and formulas specific to fluid dynamics, you can determine the appropriate pipe length needed to achieve the desired flow and pressure conditions. Additionally, factors like pipe fittings, bends, and elbows also need to be taken into account when calculating the overall pipe length required.

- Q: Are stainless steel pipes suitable for geothermal applications?

- Indeed, geothermal applications can benefit greatly from the use of stainless steel pipes. Geothermal systems rely on harnessing the earth's natural geothermal energy, which often necessitates the conveyance of hot fluids like water or steam. When it comes to this purpose, stainless steel pipes are an ideal selection due to their exceptional strength, resistance to corrosion, and ability to endure high temperatures. They possess the capability to withstand the demanding conditions typically found in geothermal environments, including the presence of acidic or corrosive fluids, while exhibiting a lower likelihood of degradation over time compared to other materials. Furthermore, stainless steel pipes boast excellent thermal conductivity, thereby ensuring the efficient transfer of heat in geothermal applications. All in all, one can confidently consider stainless steel pipes as a dependable and long-lasting choice for geothermal systems.

- Q: What is the difference between double random length and single random length stainless steel pipes?

- The difference between double random length and single random length stainless steel pipes lies in their respective dimensions and lengths. Double random length stainless steel pipes refer to pipes that are cut in random lengths twice the size of single random length pipes. Single random length stainless steel pipes, on the other hand, are cut in random lengths without any specific multiple. The purpose of using double random length pipes is to accommodate longer sections of piping in industries where longer lengths are required. These pipes are typically used in applications that involve high pressure or temperature, such as oil and gas pipelines or petrochemical plants. Single random length pipes, on the other hand, are more commonly used for general-purpose applications where shorter lengths are sufficient. They are often used in plumbing, HVAC systems, or in smaller industrial settings. In summary, the main difference between double random length and single random length stainless steel pipes is the length of the pipes. Double random length pipes are twice as long as single random length pipes and are used in industries that require longer sections of piping, while single random length pipes are more commonly used for general-purpose applications.

- Q: What are the different sizes available for stainless steel pipes?

- Stainless steel pipes are available in a wide range of sizes to cater to various industrial and residential applications. The sizes of stainless steel pipes typically depend on their nominal pipe size (NPS) or outside diameter (OD). The most common sizes for stainless steel pipes range from 1/8 inch to 48 inches in diameter. For smaller applications or plumbing systems, stainless steel pipes with NPS 1/8, 1/4, 3/8, and 1/2 are commonly used. These sizes are ideal for household plumbing, water supply lines, and low-pressure applications. As the requirements increase, larger stainless steel pipe sizes are available. Sizes such as NPS 3/4, 1, 1 1/4, 1 1/2, and 2 inches are commonly used in various industries and commercial applications. These sizes are suitable for higher-pressure applications like hydraulic systems, oil and gas pipelines, and chemical processing plants. For industrial applications that require even larger pipes, stainless steel pipes with sizes ranging from 2 1/2 inches to 48 inches in diameter are available. These large pipes are often used in heavy-duty applications such as petrochemical plants, power generation facilities, and large-scale construction projects. It's important to note that stainless steel pipes are also available in different wall thicknesses, commonly referred to as schedules. The schedule number determines the wall thickness, with higher numbers indicating thicker walls. The most common schedules for stainless steel pipes are Schedule 5, Schedule 10, Schedule 40, and Schedule 80. In summary, stainless steel pipes come in a wide range of sizes, starting from 1/8 inch and going up to 48 inches in diameter. The selection of the appropriate size depends on the specific application and the required pressure and flow requirements.

- Q: Are stainless steel pipes suitable for wastewater treatment ponds?

- Yes, stainless steel pipes are suitable for wastewater treatment ponds. Stainless steel is highly resistant to corrosion, which is essential for withstanding the harsh and corrosive environment of wastewater treatment ponds. Additionally, stainless steel pipes are durable, have a long lifespan, and can handle high-pressure systems, making them a reliable choice for wastewater treatment applications.

- Q: What are the different end connections available for stainless steel pipes?

- There are several different end connections available for stainless steel pipes, depending on the specific application and requirements. Some of the commonly used end connections include: 1. Threaded Ends: Stainless steel pipes can have threaded ends, which allow them to be easily connected to fittings or other pipes using threaded connections. This type of end connection is commonly used in plumbing and industrial applications. 2. Socket Weld Ends: Socket weld ends are another type of end connection for stainless steel pipes. They involve inserting the pipe into a socket in a fitting and welding it in place. This type of connection provides a strong and leak-proof joint, making it suitable for high-pressure and high-temperature applications. 3. Butt Weld Ends: Butt weld ends involve welding the ends of two stainless steel pipes together. This type of connection is typically used for larger diameter pipes and provides a strong and durable joint. Butt weld ends are commonly used in industries such as oil and gas, chemical processing, and power generation. 4. Flanged Ends: Flanged ends are used when the stainless steel pipe needs to be connected to equipment or components using flanges. Flanges are flat, circular discs with raised edges that allow the pipe to be bolted to the flange. This type of connection is commonly used in industries such as petrochemical, water treatment, and HVAC. 5. Grooved Ends: Grooved ends involve cutting grooves into the ends of stainless steel pipes and using grooved couplings to connect the pipes together. This type of connection is quick and easy to install, making it popular in applications such as fire protection systems and plumbing. It's important to note that the choice of end connection depends on factors such as the pipe size, pressure rating, temperature requirements, and the specific application. Consulting with a professional or referring to industry standards and guidelines can help determine the most suitable end connection for a particular stainless steel pipe.

- Q: 304 stainless steel pipe, 20*2 pressure, how many kilograms?

- 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304 is equivalent to 0Cr19Ni9 in our country(0Cr18Ni9) stainless steel. 304 chromium 19%, containing nickel 9%. The 304 is the most widely used stainless steel, heat-resistant steel, steel, steel industry utility. For food production equipment, general chemical equipment, nuclear energy, etc..

Send your message to us

304 321 316 316l Stainless Steel Seamless Pipe in Wuxi ,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords