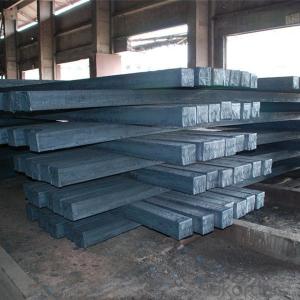

Square Steel Bar, Steel Billets Exporter (60X60-150X150)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Description:

| Product Name | Steel Billets |

| Size | 60×60mm, 100×100mm, 120×120mm, 130×130mm, 150×150mm |

| Length | 6M, 9M, 12M |

| Grade | Q195, Q235, Q275, 3SP, 5SP, 20MnSi, etc |

| Standard | ASTM, GB, JIS |

| Chemical Composition | Q235: C: 0.14-0.22% MN: 0.3-0.7% SI: 0.3% max P: 0.045%max S: 0.045%max |

| Q275 C: 0.27-0.38% MN: 0.5-0.8% SI: 0.3% max P: 0.045%max S: 0.045%max | |

| According to Customers Needs | |

| Delivery | 10-30 Days |

Detailed Image:  Production Process Image:

Production Process Image:  Shipment:

Shipment:

Logistic department established and serves for sales department. Cargo is delivered to the port by our own trucks. Both bulk and container service are available and cargo shipment is in hands of logistic staffs.

FAQ:

1: Do You Have Mills?

Yes, we have our own mills and had invested in other mills for advanced products. Besides this, we have our registered trading company for resources integration.

2: What Is Your Main Products?

We are the earliest company that researched and developed ASTM steel angles channels, and exported to USA and Canada in 2006. And we also developed JIS & En standard angles channels and I beams and exported to South Korea, South East Asia and Middle East market. Now, structural steel products, wire rod, steel plate and steel billets are all available in our company.

3: Have You Passed Global Quality System Management?

Yes, certificate was given in 2007.

4: Do You Have A Quality Check Team?

Yes, our quality check team could provide serious quality check services.

5: How About The Machine?

Continues Rolling Lines are supplied in our company. We could produce according to our guest's needs. And chemical elements and physical properties could be controlled to fit needs.

- Q: What are the applications of steel in the chemical industry?

- Steel has numerous applications in the chemical industry due to its exceptional properties. It is commonly used for constructing chemical storage tanks, pipelines, and equipment due to its high strength, durability, and resistance to corrosion. Steel is also utilized in the production of catalysts, reactors, and heat exchangers, where it can withstand high temperatures and pressure. Additionally, steel is an essential material for constructing industrial buildings, support structures, and platforms that house chemical manufacturing facilities.

- Q: How is steel used in the production of agricultural machinery and equipment?

- Steel is commonly used in the production of agricultural machinery and equipment due to its high strength and durability. It is used in various components such as frames, bodies, and blades to provide the necessary structural integrity and resistance to the demanding conditions of agricultural operations. Steel's versatility allows for the fabrication of complex shapes and designs, enabling the machinery to efficiently perform tasks such as plowing, harvesting, and transporting crops. Additionally, steel's resistance to corrosion ensures that the equipment remains operational even in harsh outdoor environments.

- Q: How are steel profiles used in the fabrication of storage racks?

- Steel profiles are commonly used in the fabrication of storage racks as they provide strength, stability, and durability to support heavy loads. These profiles are cut, shaped, and welded together to form the framework of the storage rack, creating a sturdy structure that can hold and organize various items. Additionally, steel profiles can be customized to meet specific storage requirements, allowing for the efficient utilization of space and the safe storage of goods.

- Q: How are steel products used in the construction of theme-based art and craft studios?

- Steel products are commonly used in the construction of theme-based art and craft studios for their durability, strength, and versatility. Steel beams and columns provide structural support, ensuring the stability and safety of the building. Steel panels or sheets are often used for walls, roofs, and flooring due to their resistance to fire, moisture, and pests. Additionally, steel can be easily molded and shaped, allowing for unique and artistic designs in the studio's architecture. Overall, steel products play a crucial role in creating functional and visually appealing spaces for art and craft activities.

- Q: What are the different types of steel nails and their applications?

- There are several types of steel nails, each designed for specific applications. Common types include common nails, finishing nails, roofing nails, and concrete nails. Common nails are versatile and used for general construction purposes. Finishing nails have a smaller head and are used for trim work or other finishing touches. Roofing nails are specifically designed for securing roofing materials. Concrete nails are hardened and used for fastening materials to concrete or masonry surfaces.

- Q: How are steel products different from iron products?

- Steel products are different from iron products primarily because steel is an alloy made by combining iron with carbon, while iron products are made solely from iron. This alloying process gives steel higher strength, durability, and versatility compared to iron products.

- Q: What are the different types of steel bolts and their uses in the automotive aftermarket?

- There are several types of steel bolts commonly used in the automotive aftermarket, including hex bolts, flange bolts, carriage bolts, and specialty bolts like wheel bolts and exhaust manifold bolts. Hex bolts are the most commonly used and are suitable for a wide range of applications. Flange bolts have a built-in washer-like flange that distributes the load and provides extra strength. Carriage bolts have a smooth, rounded head and are often used in applications where a smooth finish is desired. Specialty bolts like wheel bolts are specifically designed for securing wheels to the vehicle, while exhaust manifold bolts are used to connect the exhaust manifold to the engine block. Each type of steel bolt has its own specific use and is selected based on the requirements of the automotive aftermarket applications.

- Q: What are the different types of steel doors and windows?

- There are several different types of steel doors and windows, including flush doors, panel doors, sliding doors, casement windows, and fixed windows.

- Q: What are the uses of steel in the construction of hotels and resorts?

- Steel is widely used in the construction of hotels and resorts due to its exceptional strength and durability. It serves various purposes such as providing structural support, forming the framework of the building, and reinforcing concrete structures. Steel beams and columns are used to create large open spaces, allowing for flexible and efficient floor plans. Additionally, steel is utilized in the construction of staircases, elevator shafts, and roofing systems. Its fire-resistant properties and ability to withstand extreme weather conditions make it an ideal choice for ensuring the safety and longevity of hotels and resorts.

- Q: How is steel tubing used in the manufacturing of heat exchangers?

- Steel tubing is commonly used in the manufacturing of heat exchangers due to its excellent heat conductivity, durability, and corrosion resistance. The tubing is often formed into intricate coil or finned shapes, allowing for maximum surface area contact with the heat transfer fluid. This facilitates efficient heat transfer between the hot and cold fluids, enabling effective temperature regulation in various industrial processes such as power generation, HVAC systems, and chemical manufacturing.

Send your message to us

Square Steel Bar, Steel Billets Exporter (60X60-150X150)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords