Mirafi Non Woven Geotextile Fabric Spun-Bonded PP Non Woven Mulching Mats / Weed Barrier Fabric / Mulching Rolls

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

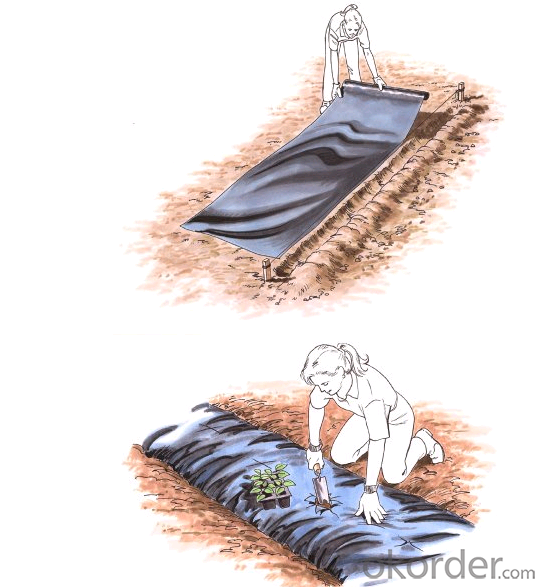

The weed control mat is made of environmentally friendly raw materials, pp woven fabric. It used to prevent the growth of weed, without the use of potentially dangerous chemical sprays or labor intensive hoeing. Once installed, weed mat will continue providing protection for years without maintenance.

They are permeable fabrics, which allow air, water and nutrients to pass through, and designed to block out the sun to reduce photosynthesis and stop weed growth.

Specification

Item No. | XG-SNN-05 | XG-SNN-06 | XH-SNN-07 | XH-SNN-08 | XH-SNN-09 |

Product specifications | 70GSM | 90GSM | 100GSM | 110GSM | 120GSM |

Material | PP/PE | ||||

model name | Plastic ground cover | ||||

width | 1m-6m | ||||

length | As your requirement | ||||

color | Green. black | ||||

type | warp knitted | ||||

useful life | 2-5 years | ||||

UV | 1%-5% | ||||

MOQ | 2Tons | ||||

packing | one roll one plastic bag | ||||

payment | T/T L/C | ||||

delivery time | 20 -30 days | ||||

package | 20ft: 8 t | ||||

Certificate | ISO9001 REACH EO | ||||

roll diameter | 15CM-38CM | ||||

market | Europe | ||||

Features

1. Weed suppressant and drainage control landscaping fabric

2. Easy to use, Environmentally friendly

3. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

4. Reduces the level of watering required due to the slower rate of water evaporation

Application

1. Excellent Weed Control

2. Moisture, fertilizers, air reach plants to allow for healthy soil

3. Good water and air permeability

4. Exceptional toughness and strength

5. Durable, tear-resistant; won't rot or mildew

6. Lightweight, easy to install, follows natural ground contours

7. Ideal for use in landscaped beds, under decks and walkways.

Packaging & Delivery

| Packaging Details: | Packed In Roll Or In Bales Or Cartons Or According To Customers Requirement |

| Delivery Detail: | 20 Days After Order Confirmed |

FAQ

1, Samples Policy

Samples are free, but the freight is on customers' charge

Samples will usually be sent out in one day.

2, Prices

As for the prices, we need you to provide us weight, color, width and usage so that

we can quote you best.

3, How to place an order?

Inquiry

Reply

Sample

Contract

Receiving deposit& production

Testing& Packing

Delivery

Receiving

- Q: What are the considerations for geotextile selection in road rehabilitation projects?

- When selecting geotextiles for road rehabilitation projects, there are several important considerations to keep in mind. Firstly, the geotextile should have sufficient strength and durability to withstand the expected loads and stresses in the road environment. It should also be resistant to degradation from environmental factors such as ultraviolet (UV) radiation and chemicals. Another consideration is the desired function of the geotextile. Different types of geotextiles offer various benefits, such as separation, filtration, drainage, or reinforcement. The specific requirements of the road project will determine which function is most important. Additionally, the properties of the soil and subgrade should be considered when selecting a geotextile. The geotextile should be compatible with the soil type and provide the necessary soil stabilization or separation capabilities. It is crucial to assess the project's soil conditions and consult with geotechnical engineers or experts to determine the appropriate geotextile specifications. Lastly, cost-effectiveness is an essential consideration. The selected geotextile should provide the desired performance while being economically viable for the project. Considering the long-term benefits and expected lifespan of the geotextile can help in making a cost-effective decision. Overall, the considerations for geotextile selection in road rehabilitation projects involve strength, durability, desired function, compatibility with soil conditions, and cost-effectiveness.

- Q: How do geotextiles contribute to soil separation?

- Geotextiles contribute to soil separation by acting as a barrier between different soil layers, preventing them from mixing or interacting. This separation helps to maintain the stability and integrity of the soil structure, prevents erosion, and enhances the overall performance of the soil in various construction and landscaping applications.

- Q: How do geotextiles aid in the reduction of settlement-induced cracking?

- Geotextiles aid in the reduction of settlement-induced cracking by providing a stable and reinforced base for construction projects. They distribute the load and enhance the soil's bearing capacity, preventing excessive settlement and subsequent cracking in the structure.

- Q: Geotextile and geogrid the same do

- Not the same, this is two kinds of products, my user name professional manufacturer phone! The The

- Q: Can geotextiles be used in geosynthetic clay liners?

- Yes, geotextiles can be used in geosynthetic clay liners. Geotextiles are often used as a protective layer or separator between the clay liner and other materials in order to enhance the performance and longevity of the geosynthetic clay liner system.

- Q: How do geotextiles help in preventing sinkhole formation?

- Geotextiles help in preventing sinkhole formation by providing reinforcement and stabilization to the soil. They act as a barrier, preventing the migration of soil particles and reducing the potential for erosion. This reinforcement helps to maintain the integrity and strength of the soil, minimizing the risk of sinkhole formation.

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing additional strength and stability to the bags. They act as a barrier between the bag material and the surrounding soil, preventing soil erosion and enhancing the bag's structural integrity. The geotextiles distribute the load evenly across the bag, reducing stress concentrations and preventing the bags from bursting or tearing under heavy loads. Additionally, they allow for effective drainage of water, maintaining the bags' stability and preventing water accumulation that could potentially weaken the bags.

- Q: Are geotextiles resistant to extreme temperatures?

- Yes, geotextiles are generally resistant to extreme temperatures. They are designed to withstand a wide range of temperatures, both hot and cold, without significant degradation or loss of performance.

- Q: You produce 700 grams of high-strength polypropylene geotextile it?

- 700 grams of high-strength polypropylene geotextile is designed for high-speed rail sliding layer of high-strength wear-resistant geotextile, our products in the West high-speed rail passenger line, OKorder and Hangzhou and other high-speed rail lines have applications.

- Q: How do geotextiles improve the performance of geogrids?

- Geotextiles improve the performance of geogrids by providing additional reinforcement and stabilization. They work in tandem with geogrids to enhance their strength, prevent soil erosion, and distribute loads more evenly. The geotextile acts as a separation layer, preventing the mixing of different soil layers and allowing water to flow freely, thereby reducing pore pressure. This combination enhances the overall stability, durability, and effectiveness of geogrids in various civil engineering applications.

Send your message to us

Mirafi Non Woven Geotextile Fabric Spun-Bonded PP Non Woven Mulching Mats / Weed Barrier Fabric / Mulching Rolls

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords