Splice Routel AJ25

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

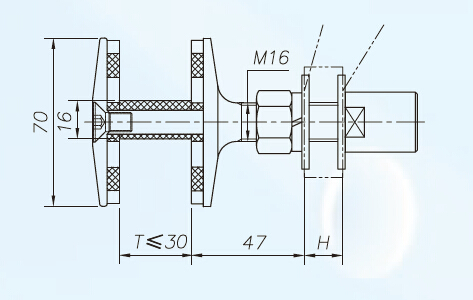

Product Name | Splice Routel AJ25 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 0~30mm |

Bolt Size | M16 |

Max. axial bearing capacity | 6000N |

Max. Radial Bearing capacity | 2000N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

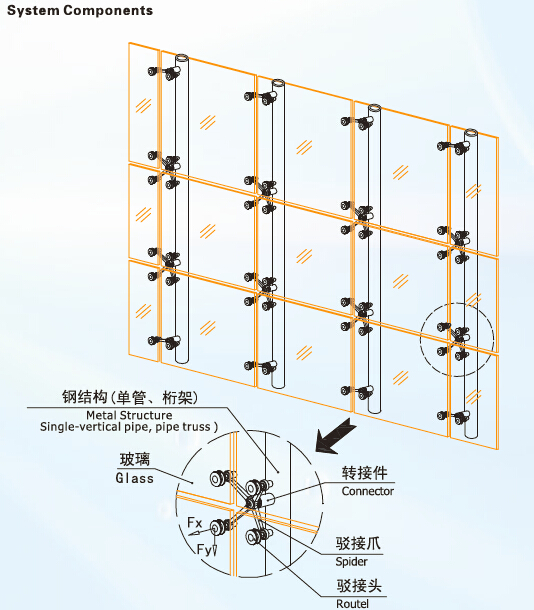

- Q: The purpose and advantages of splicing claws

- The dotted glass curtain wall is made up of other components such as splicing claws and spliced joints, which are used as an important tool for connecting the glass curtain wall.

- Q: Diamond knife can pierce twelve PCT tempered glass?

- Diamond knife is not the glass pierced, but the glass a long mouth, and then stress the broken line above the broken, it is easy to board off. It is very difficult to cut the twelve-piece tempered glass directly.

- Q: Curtain wall claw claw how much appropriate? How much is a square? Please professional answer, plus points plus points

- See you how thick the glass!

- Q: Tempered glass shed with 22o of the split jaws, how to calculate the location of the glass hole ah

- Usually between the glass to stay 10mm glue, two pieces of glass split hole center spacing 220mm, hole to the glass edge of the distance: (220-10) / 2 = 105 mm

- Q: Steel glass canopy glass is tiled or split jaws good

- Light steel glass canopy focus on just the material for the light steel, tempered glass canopy focus on the glass material for the tempered glass, are glass canopy, but the name of the focus is not the same

- Q: What is the splice

- The spliced connector is a fitting for a glass curtain.

- Q: Will the glass curtain wall, 1600 * 2500 glass, 8 +8 glued rubber, with more of the appropriate claw claw, more than 60 meters of the building, so much glass stress enough?

- I do curtain wall accessories manufacturers, I suggest you use 304 # 250 heavier, do not use light, to ensure the safety of the project Oh! Need to see my information

- Q: Is there a stainless steel splicing claw with the same price but cheaper manufacturers?

- Some, a lot of It's harder to find than it is.

- Q: Split jaw type 3O0 type open large holes, the glass on the opening of the hole

- The general use of the 120 150 180 220 model is the point of grasping the relative 2 grasp the distance between the center of the nest

- Q: I do not understand the hope that my friends guide the guidance teach me, the general is divided into 150 160 type 200 type 220 type 250 type (4 claw) a set of refers to the splicing claws +4 turn joints +1 turn Parts There is the corresponding model with the corresponding splicing? Or with the model has nothing to do with the folder of the glass? Such as 150 can be used to replace the type of 200 can not use? Who explained the next

- The concept of a set of pieces is not necessarily a claw 4 head, corner parts useful a claw a head, there are two jaws both head. (You can look at the point of the glass curtain wall, the streets can be seen everywhere, the corner is a claw or head of a head) as to what time is what model is to look at the curtain wall design force and then select the model calculation After the final model) specific to which manufacturers of materials is generally there are three possible (Party designated, the curtain wall company designated, design specified).

Send your message to us

Splice Routel AJ25

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords