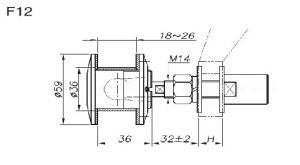

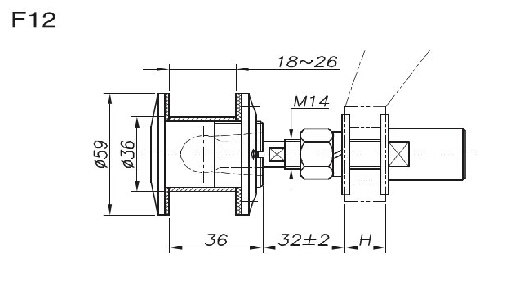

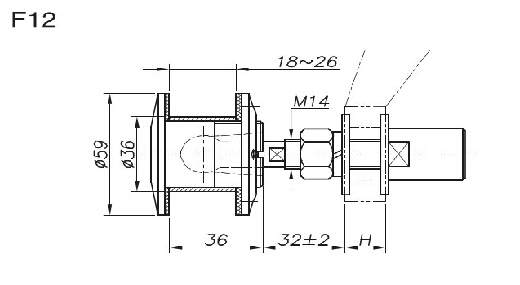

Glass spider fitting, Stainless steel Flat Cap Routel F12 (18~26mm glass)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: | Glass spider fitting, Stainless steel Flat Cap Routel F12 (18~26mm glass) |

| Item Number: | F12 |

| Material: | Stainless Steel 304&316 |

| Sizes: | used for all size glass spider, for glass thickness 8~18mm |

| Finish: | High Satin/Mirror Polished |

| Characteristic: | Flat Cap routel with rubber cover,sunk screw |

| Glass Thickness of scope: | 18-26mm Thickness |

| Weight: | 0.70kg |

| Port: | SHENZHEN Sea Port/Airport |

| Packing: | 1)Plastic Wrap is Wrapped. 2)Foam Bag.3)Small Carton Box |

| Minimum Order Quantity: | 100 PCS |

| Delivery Time: | 10~25 DAYS AFTER DEPOSIT |

| Payment Way: | T/T OR L/C |

| Supply Ability: | 5000PCS/Month |

Product Picture and Dimensions:

Other more Products used for Curta wall:

Connector Countersunk cap routel

Long single arm spider Right angle, two arms spider

Short Single arm spider Four arms spider

- Q: The purpose and advantages of splicing claws

- The appearance of the glass curtain wall with the connection of the pawl is transparent, and the interior space and the outdoor environment are fused due to the lack of wall and good lighting. Split claws support structure and diverse, to meet the needs of different building structures and decorative effects. Splicing jaw pieces with spherical hinge connection, with the ability to absorb deformation, the security is also a great protection.

- Q: Viagra Tile 8h005 price

- The point-type glass curtain wall is composed of splice joints, splicing jaws, adapters and other components, the main claw claw as a support link joints, and transfer load to a fixed support structure on the system

- Q: Glass curtain wall glass installation process requirements which out

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone.

- Q: What is the point of the ribbed curtain wall

- Point refers to the point of the type, the glass panel is fixed by the stainless steel dial system; rib dial refers to the dial system is fixed in the rear of the panel on the floor. The most common is the glass ribs point of the curtain wall.

- Q: What is the between glass and steel frame?

- There is a thing called the splicing claws, or to tough accessories to ask, they have a frameless curtain wall accessories

- Q: How is the glass curtain wall attached to the steel frame fixed on the steel frame

- Steel structure point curtain wall cylindrical adapter seat welded to the steel structure, the splicing claw screw to the adapter seat, the joint and then fixed to the splicing claw

- Q: Are there any requirements for the weld grade of the curtain wall connection? Thank you!

- This is generally described in the design of the curtain wall

- Q: Stainless steel splicing claws attached to what steel structure above

- Stainless steel splicing jaw pieces of the choice of models to see you mainly use the glass size, carrying the wind pressure, weight.

- Q: 304 stainless steel splicing claws the price is how much, what quality and cheap manufacturers

- Also depends on what size you want. Prices in the tens to hundreds of range. Last month, our company set a number of split claws, manufacturers called Jiangsu Jie Chen, dozens of dollars a set, okay, no rust.

- Q: Curtain wall panel installation control points which

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone. The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem. The first is the preparation before the installation.

Send your message to us

Glass spider fitting, Stainless steel Flat Cap Routel F12 (18~26mm glass)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords