Countersunk Cap Routel for Spider AT44

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

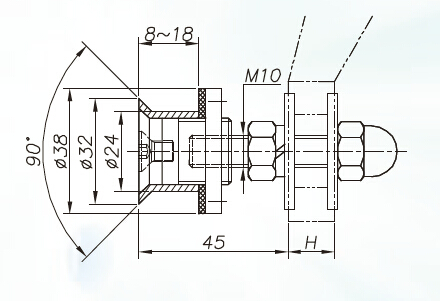

Product Name | Countersunk Cap Routel for Spider AT44 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 8~18mm |

Bolt Size | M10 |

Max. axial bearing capacity | 2500N |

Max. Radial Bearing capacity | 1200N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

Countersunk Cap Routel for Spider AT44

- Q: There are several types of modular glass curtain wall installation

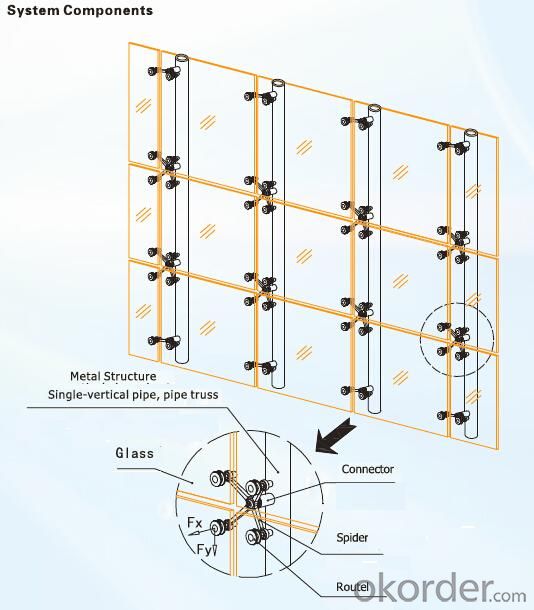

- Glass rib structure point of the glass curtain wall system Detailed description of the scope of application: glass rib structure for open, large span of the building. Tips: 1. Glass panel through the glass rib structure fixed on the support structure. The load of the panel is transmitted through the glass rib structure to the support structure and the main structure. 2. Splicing claws are divided into X-shaped, H-shaped, mountain-shaped, etc .; according to the surface treatment is divided into mirror light, matte, fluorocarbon spray; by material is divided into stainless steel, aluminum and so on. Recommendation: steel gluing to be used to split the glass ribs, at a certain height, should increase the pull knot measures. Drawstring, cable structure point of the glass curtain wall system specific scope of application: This system is suitable for large and wide layers of the gap between.

- Q: What is the difference between the price of the pick up claw?

- Material 201,304,316, from time to good, the most commonly used is 304. The larger the size, of course, the price is smaller than the size of the expensive

- Q: What is the meaning of the radial curtain of the glass curtain wall?

- Stainless steel splicing claw glass curtain wall is composed of splicing joints, splicing claws, adapters and other components, the main part of the hook as a support link joints, and transfer load to the fixed support structure system, is connected to the glass curtain wall is an important Accessories.

- Q: Viagra Tile 8h005 price

- The point-type glass curtain wall is composed of splice joints, splicing jaws, adapters and other components, the main claw claw as a support link joints, and transfer load to a fixed support structure on the system

- Q: What is the difference between a curtain wall countersunk connector and a floating head connector?

- First of all, I think you are referring to the point of the glass curtain wall, split the claw kit in the split connector. There is a sort of splashing and splashing.

- Q: Glass curtain wall glass installation process requirements which out

- The first is the preparation before the installation. Stainless steel splicing jaws Before installing, check whether the mounting position of the splicing jaws is accurate. Proof of the steel structure of the main support of the vertical, elevation, beam height and level of compliance with the design requirements, with particular attention to the installation of holes in the review. And then clean the stainless steel and sucker, according to the weight of stainless steel and sucker to determine the number of suction cups. And use the steel brush to clean the surface of the steel tank and the bottom of the groove, the bottom of the stainless steel stainless steel U-shaped steel groove should be added chloroprene rubber pad from the edge of the stainless steel 1/4 width. Field installation of stainless steel splicing claws need to pay attention to the point is due to the specific size of the splicing system size can not be wrong, you must use the torque wrench to determine the torque, the purpose of doing so is to ensure that the joints at the air tightness and watertight Sex. Then install the splice and stainless steel on the mounting platform and install it with the splicing jaws. After the installation of the scene, to ensure that the level of stainless steel deviation within the allowable range, should pay attention to adjust the position up and down about. After all the adjustments are completed, the overall flatness of the facade should be checked to ensure correctness.

- Q: What are the specifications of the curtain wall

- 220 series, 250 series, generally use these two series more.

- Q: What are the specifications of the stainless steel jaws?

- 150 type splicing claws (size 150MM) Features: relatively small, commonly used in canopy, double glass area is not large. Small size is cheap,

- Q: What is the use of borehole during the production of tempered glass?

- Drilling is the need for glass mounting - fixing the glass through the holes.

- Q: Can the splicing jaw be welded to the stainless steel tube?

- Split claws support structure and diverse, to meet the needs of different building structures and decorative effects. Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, in the security also has a great protection.

Send your message to us

Countersunk Cap Routel for Spider AT44

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords