Splice Routel AJ11

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

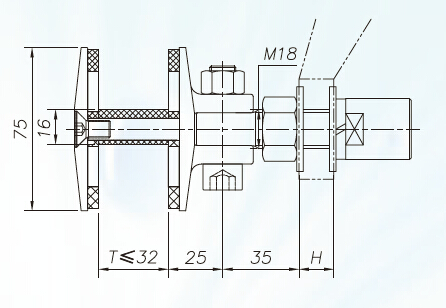

Product Name | Splice Routel AJ11 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 0~32mm |

Bolt Size | M18 |

Max. axial bearing capacity | 6000N |

Max. Radial Bearing capacity | 2500N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

- Q: There are several types of modular glass curtain wall installation

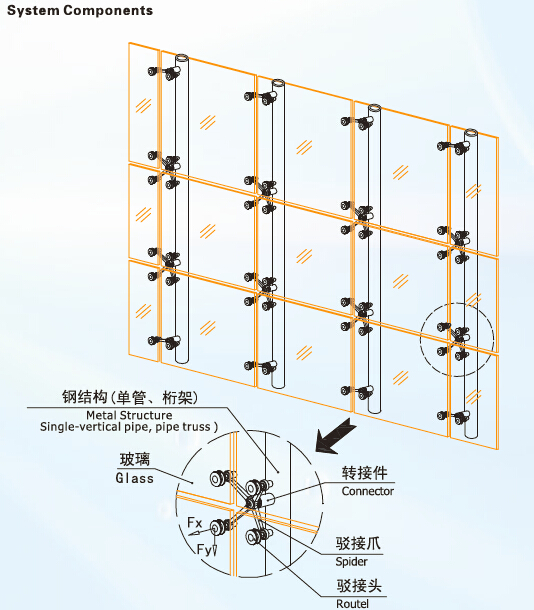

- External Circulation Double Curtain Wall System Description Tips: 1. According to the principle of hot air and chimney effect, so that fresh air into the room, the indoor dirty air out of the room, and can effectively prevent dust into the room. 2. In inconvenient weather conditions, indoor air can be achieved with the outside world to exchange fresh air. Steel structure point of the glass curtain wall of the specific description of the scope of application: the larger span but the general requirements of the building when the general use of steel structure. Tips: 1. In the steel truss, grid and other installation of steel claws, glass panel load through the steel structure of the bearing structure to the main structure. 2. This system is composed of curved steel pipe reticulated shell system and curved surface cable system. The surface steel pipe reticulated shell system is subjected to external load, and the plane is stabilized by the surface cable system. 3. In the steel pipe between the use of universal hinge-shaped embedded. Single cable structure point of the glass curtain wall system specific description of the scope of application: suitable for the entrance of the atrium and other large span openings. Tips: 1. Support structure for the prestressed single-layer cable structure, glass panel load through the high-strength steel hinge line composed of single-layer cable structure to the main structure. 2. Structure Based on the principle of tennis racket, the cable network through the applied prestress to produce resistance to the plane load stiffness. 3. Single cable structure curtain wall due to the need for large deformation of the steel hinge line to resist wind pressure, so the cable network deflection is generally controlled at L / 50, larger than the general wall.

- Q: What is the difference between the price of the pick up claw?

- With material and size.

- Q: Who knows which factory is good? Recommended!

- Budget can be considered to find a factory cooperation, our company has worked in Jiangsu Jie Chen, material quality standards, the price is cheap enough, the other do not know, you can find a few and then compare the next decision.

- Q: What is the 250 pick up claws

- 250 refers to the hole distance, split the claw is the curtain wall link. The splicing claws offer about $ 300.

- Q: What is the between glass and steel frame?

- Foam double-sided adhesive paste separated, both sides of the glass glue.

- Q: What are the accessories of the point-supported glass curtain wall?

- Point-type glass curtain wall accessories are stainless steel curtain wall adapter, split joints, split claws, glass clip, handrail pieces, rain canopy accessories, support rods, rods, cable, stainless steel mini cable and so on.

- Q: How to do the size of the glass shed with stainless steel claws

- According to the size of the selected splicing claws on the joints.

- Q: What is a round steel nail on a glass curtain wall?

- You say is the point of the glass curtain wall of the steel claws, you see the circular nails are steel claws through the glass after the floating head or countersunk head

- Q: Used in the glass canopy on the distance between the claw claw how much, generally what is required in the canopy, I consult a few, the difference is a bit big, dizzy.

- Usually stay between 10mm glass glue joints, connections are two glass center hole spacing 220mm, from the heart to the glass edge of the hole is: (220-10) / 2 = 105mm

- Q: Glass curtain wall connector (including the base, split joints, split jaws) how much money a set of prices

- Material, 201,304 or 316, the latter material is better than the former, look at the thickness of the glass, the greater the thickness of the higher the price of the joints, sub-models, different models are completely different prices, such as 200 pieces of the pieces and 4080 gap Go, sub-manufacturers, a penny of goods, some say hundred dollars of 250 pieces of pieces, it is not as good as you get four steel welding together

Send your message to us

Splice Routel AJ11

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords