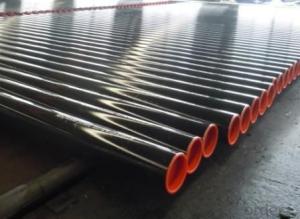

ASTM 53 ERW welded pipes--Tube and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- Based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of ASTM 53 ERW welded pipes--Tube and Pipe:

Standard:

API SPEC 5L, API SPEC 5CT, ASTM A53, GB/T9711.1

Steel Grade:

API SPEC 5L: B, X42, X46, X52, X56, X60, X65

API SPEC 5CT: J55, K55, N80, L80-1

ASTM A53: A, B, C

GB/T9711.1:L242、L290、L320、L360、L390、L415、L450

Usage/Application of ASTM 53 ERW welded pipes--Tube and Pipe:

It is widely applied to line pipe and casing and tubing in oil transportation and casing field, and it is used in low,high pressure liquid and gassy transportation and it is also good structure pipe (for furniture, window, door, building , bridge, mechanical etc).

Packaging of ASTM 53 ERW welded pipes--Tube and Pipe:

Bundles with anti-rust painting and with plastic caps

- Q: What are the different types of supports used for aboveground steel pipes?

- There are several types of supports commonly used for aboveground steel pipes, including pipe hangers, pipe clamps, pipe saddles, and pipe shoes. These supports are designed to provide stability and prevent excessive movement or vibration of the pipes, ensuring their proper alignment and preventing damage.

- Q: How are steel pipes tested for quality?

- Steel pipes are tested for quality through various methods, including visual inspection, non-destructive testing (NDT) techniques such as ultrasonic testing, magnetic particle testing, and radiographic testing. Additionally, mechanical properties like tensile strength, hardness, and toughness are evaluated to ensure the pipes meet the required specifications. Various standards and guidelines are followed to ensure the quality and safety of steel pipes.

- Q: What is the difference between steel pipe and ductile iron pipe?

- Steel pipe and ductile iron pipe are commonly utilized in various industries to transport fluids and gases. Nevertheless, there exist notable distinctions between the two materials. One primary difference lies in their composition. Steel pipe primarily consists of iron and carbon, with additional alloying elements to enhance strength and corrosion resistance. Conversely, ductile iron pipe is a form of cast iron that has undergone treatment to improve ductility and toughness. It contains higher levels of carbon and silicon, along with small amounts of other elements like magnesium and copper. Another difference is their strength and durability. Steel pipe is renowned for its high strength, enabling it to endure greater pressures and stresses compared to ductile iron pipe. It also exhibits superior resistance to impact and bending, making it suitable for applications requiring robustness. Ductile iron pipe, although not as strong as steel, still offers good strength and durability, particularly in scenarios involving external damage or heavy loads. Corrosion resistance is another crucial factor. Steel pipe typically exhibits greater resistance to corrosion due to the inclusion of alloying elements such as chromium and nickel. This renders it well-suited for applications prone to high corrosion risks, like pipelines carrying corrosive fluids. Ductile iron pipe, while possessing some corrosion resistance, may necessitate additional protective coatings to enhance its durability in corrosive environments. Installation and maintenance also differ between these two pipe types. Steel pipe is generally lighter and more manageable, facilitating easier installation. It also allows for welding, thereby providing greater construction flexibility. Ductile iron pipe, being a cast iron material, requires more specialized installation techniques such as mechanical joints or flanges. If mishandled, it is also more prone to cracking during installation. In terms of cost, steel pipe typically incurs higher expenses compared to ductile iron pipe. This stems from the higher cost of raw materials and the additional processing involved in steel pipe production. However, it is crucial to consider the overall lifecycle cost, as steel pipe's increased strength and corrosion resistance may result in lower maintenance and replacement expenses in the long run. In conclusion, while both steel pipe and ductile iron pipe have their respective advantages and applications, the choice between the two depends on factors such as strength requirements, corrosion resistance, installation methods, and budget considerations. Careful assessment of these factors will aid in determining the most suitable pipe material for a specific application.

- Q: How are steel pipes connected or joined together?

- Steel pipes are typically connected or joined together using various methods such as welding, threading, or using mechanical fittings.

- Q: How are steel pipes protected from corrosion?

- Steel pipes are protected from corrosion through various methods such as applying protective coatings, using sacrificial anodes, or employing cathodic protection systems.

- Q: What are the main aspects of precision steel tubes?

- Products according to their application areas are divided into: automotive, precision machinery tubes; power plants, nuclear power tubes; titanium and titanium alloy tubes; chemical tubes; varieties include colored, black; seamless; welding; general and special-shaped

- Q: How do steel pipes differ from other types of pipes?

- Steel pipes possess several distinct characteristics that set them apart from other pipe types. Primarily, their strength and durability are well-known. They exhibit remarkable resistance to heat, pressure, and corrosion, rendering them suitable for numerous applications. Additionally, their robustness allows them to bear heavy loads and offer an extended service life. One distinguishing feature of steel pipes lies in their versatility. They can be manufactured in various shapes and sizes to fulfill specific project requirements. This adaptability has contributed to their popularity across a diverse range of industries, including construction, oil and gas, water treatment, and manufacturing. Moreover, steel pipes exhibit exceptional thermal conductivity, facilitating efficient heat transfer between different areas. Consequently, they prove suitable for applications involving heating and cooling systems, as well as the transportation of hot fluids or gases. Furthermore, steel pipes are renowned for their resistance to fire. They possess a high melting point and are not easily ignited or conducive to the spread of flames. This characteristic is particularly critical in applications where fire safety is a concern, such as buildings or industrial facilities. Lastly, although steel pipes may entail a higher initial cost compared to other pipe types, their long-term benefits, such as durability and low maintenance requirements, often outweigh the initial investment. Additionally, steel pipes are highly recyclable, making them an environmentally friendly choice. In summary, steel pipes stand out due to their strength, durability, versatility, excellent thermal conductivity, fire resistance, and recyclability. These remarkable qualities establish steel pipes as the preferred option for a wide range of applications across various industries.

- Q: What kind of argon arc welding wire is used for 16Mn steel pipe?

- JB/T4709 recommends H10MnSi, but H10MnSi allows a lower value of strength of 430MPa, which does not match the parent material. I think American Standard is selected according to the selection of welding wire ER70S-6 GB ER50-6 wire can guarantee the equivalent strength of parent materials, and Si, Mn content can also guarantee the deoxidation effect, the weld joint is not easy to produce pores.

- Q: How are steel pipes stored and transported?

- To ensure the safety and prevent damage of steel pipes, a systematic and efficient approach is employed for their storage and transportation. In terms of storage, designated areas are used to either horizontally or vertically stack the pipes. In the case of vertical stacking, custom-made racks or stands are utilized to provide support and prevent rolling or collapsing. This method not only saves space but also allows for easy accessibility when required. To safeguard steel pipes against corrosion and environmental elements, a layer of paint or other protective materials is often applied. Furthermore, pipes may be stored indoors in warehouses or storage facilities to shield them from unfavorable weather conditions. In terms of transportation, depending on the distance and destination, steel pipes are typically loaded onto trucks, railcars, or ships. Specialized equipment such as cranes or forklifts is employed to handle and load the pipes onto these vehicles. To prevent movement during transit, the pipes are tightly secured using straps, chains, or braces. This ensures stability and eliminates the risk of damage to the pipes themselves or other cargo. For long-distance transportation, steel pipes are often transported in bundles or stacks, reinforced to provide additional security. They may also be packed in protective coverings or containers to shield them from moisture, dust, or impacts. Overall, the storage and transportation of steel pipes necessitate meticulous planning, proper handling, and appropriate protective measures to uphold their integrity and quality throughout the entire process.

- Q: What are the different methods of heat treatment for steel pipes?

- Some of the different methods of heat treatment for steel pipes include annealing, normalizing, quenching, and tempering. Annealing involves heating the steel pipe to a specific temperature and then slowly cooling it to make it softer and more ductile. Normalizing is a similar process but involves air cooling instead of slow cooling. Quenching is a rapid cooling process that results in a hardened and brittle steel pipe. Tempering follows quenching and involves reheating the steel pipe to a lower temperature to reduce the brittleness and improve its toughness.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 1997 |

| Annual Output Value | Above Three Million To Five Million RMB |

| Main Markets | Main land |

| Company Certifications | ISO 9001:2010;API 5L; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 40% - 50% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ASTM 53 ERW welded pipes--Tube and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- Based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords