Soil Stabilisation Geogrids - Polyester Geogrid with PVC Coated Warp Knitted for Roadbed/Airport/Railway/Slope/Retaining

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Coated Warp Knitted Polyester Geogrid for Roadbed/Airport/Railway/Slope/Retaining Wall Reinforcement

1. Introduction of PVC Coated WarpKnitted Polyester Geogrid for Roadbed/Airport/Railway/Slope/Retaining Wall Reinforcement

1). Made of PET (Polyester)--- synthetic fiber;

2). Technics: Warp-knitted oriented structure; Knit the filament into met, and then coated PVC;

3). Applied widely in soft groundsill and roadbed reinforcement;

2. Features of PVC Coated Warp Knitted Polyester Geogrid for Roadbed/Airport/Railway/Slope/Retaining Wall Reinforcement

1). High tensile strength, high-volume, low creep;

2). Anti-aging and anti-brittle fracture;

3). Good and easy combination with gravel of a variety of design;

4). Easy construction: low weight, easy operation, simple construction

3. Application of PVC Coated Warp Knitted Polyester Geogrid for Roadbed/Airport/Railway/Slope/Retaining Wall Reinforcement

1). Enhancement soft roadbed and isolation from other base earth material of all kinds of high-grade road, railroad;

2). Strengthen the river bank and the slope of embankment;

3). Strengthen the bridge connection surface.

4. Specification of PVC Coated Warp Knitted Polyester Geogrid for Roadbed/Airport/Railway/Slope/Retaining Wall Reinforcement

1) standard type:

performance/specification | PET-20-20 | PET-30-30 | PET-40-40 | PET-50-50 | PET-80-80 | PET100-100 | |

Stretching ratio % | 13% | ||||||

Center distance of the network mm | 12.7X12.7 25.4X25.4 40X40 | ||||||

Breadth m | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | |

PET120-120 | PET140-140 | PET180-180 | PET200-200 | PET300-300 | PET400-400 | PET500-500 | PET600-600 |

13% | |||||||

120 | 140 | 180 | 200 | 300 | 400 | 500 | 600 |

120 | 140 | 180 | 200 | 300 | 400 | 500 | 600 |

12.7X12.7 25.4X25.4 40X40 | |||||||

1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 |

2)heterogeneous type:

performance/specification | PET-50-30 | PET-60-35 | PET-80-30 | PET-80-50 | PET100-50 | PET100-85 | |

Stretching ratio % | 13% | ||||||

intensity KN/m | Vertical | 50 | 60 | 80 | 80 | 100 | 100 |

Horizontal | 30 | 35 | 30 | 50 | 50 | 85 | |

Center distance of the network mm | 12.7X12.7 25.4X25.4 40X40 | ||||||

Breadth m | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | |

PET120-50 | PET140-60 | PET160-80 | PET180-100 | PET200-100 | PET300-200 | PET400-300 | PET600-400 |

13% | |||||||

120 | 140 | 160 | 180 | 200 | 300 | 400 | 600 |

50 | 60 | 80 | 100 | 100 | 200 | 300 | 400 |

12.7X12.7 25.4X25.4 40X40 | |||||||

1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 |

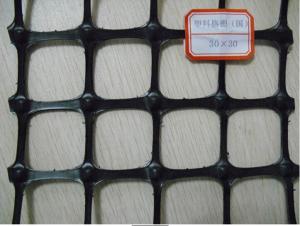

5. Photos of PVC Coated Warp Knitted Polyester Geogrid for Roadbed/Airport/Railway/Slope/Retaining Wall Reinforcement

6.RFQ

1. What's your payment terms?

T/T, L/C at sight

2. What's your delivery time?

Within 15days against prepayment received or original L/C

3. What's your pacakge?

Woven bag

- Q: Are geogrids suitable for use in slope stabilization for mining haul roads?

- Yes, geogrids are suitable for use in slope stabilization for mining haul roads. Geogrids are engineered materials that provide reinforcement and stability to soil, improving its load-bearing capacity. They are commonly used in various applications, including slope stabilization, to prevent soil erosion and maintain the integrity of the road. By distributing the load more evenly and reducing the potential for soil movement, geogrids enhance the safety and durability of mining haul roads.

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that a smaller aperture size typically leads to better performance. A smaller aperture size allows for better soil confinement and interlock, resulting in improved load distribution and higher tensile strength. This enhanced performance helps to prevent soil erosion, increase stability, and enhance the overall durability of geogrid structures.

- Q: How do geogrids help in soil reinforcement?

- Geogrids help in soil reinforcement by distributing the load applied to the soil over a wider area, thereby reducing the pressure on the soil and improving its stability. They act as a reinforcement material, providing tensile strength to the soil and preventing it from sliding or shifting. Additionally, geogrids enhance the cohesion between soil particles, increasing the overall strength and preventing the formation of cracks or failures.

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving polyester or polypropylene yarns together, creating a strong and stable grid structure. On the other hand, a non-woven geogrid is made by bonding polyester or polypropylene fibers together, forming a random network of filaments. This results in different characteristics and performance. Woven geogrids typically have higher tensile strength and are more rigid, making them suitable for applications requiring load distribution and soil reinforcement. Non-woven geogrids, while generally having lower tensile strength, offer excellent filtration and separation capabilities, making them ideal for erosion control, drainage, and subgrade stabilization.

- Q: What are the design considerations for geogrid-reinforced structures?

- Some design considerations for geogrid-reinforced structures include the type and strength of the geogrid material, the soil characteristics and conditions, the required structural integrity and stability, the anticipated loads and stresses, the desired lifespan of the structure, and the overall cost-effectiveness of the design. Additionally, factors such as installation and construction techniques, environmental impacts, and local regulations may also need to be taken into account during the design process.

- Q: What are the design considerations for geogrids in reinforced soil slopes prone to seismic activity?

- Design considerations for geogrids in reinforced soil slopes prone to seismic activity include: 1. Geogrid selection: Choosing a geogrid with sufficient strength, stiffness, and durability to withstand the dynamic forces generated during seismic events is crucial. The geogrid should have high tensile strength and low elongation properties to effectively restrain the soil mass. 2. Connection details: Ensuring proper connection between the geogrid and the facing system is essential. The connection should be able to accommodate the movement and deformation of the soil during seismic events without compromising the stability of the reinforced slope. 3. Slope geometry: The slope geometry should be carefully designed to minimize the risk of failure. Factors such as slope angle, height, and overall stability need to be considered to prevent excessive stress on the geogrid and ensure it can effectively reinforce the soil. 4. Soil properties: Understanding the behavior of the soil under seismic loading is crucial for designing the geogrid reinforcement. The soil properties, such as shear strength, liquefaction potential, and settlement characteristics, should be evaluated to determine the appropriate geogrid type, spacing, and embedment depth. 5. Dynamic analysis: Conducting dynamic analysis to assess the potential response of the reinforced slope to seismic forces is important. This analysis helps in determining the required strength and stiffness of the geogrid and ensures that the slope remains stable during seismic events. 6. Construction quality control: Implementing proper construction techniques and quality control measures during geogrid installation is vital. Ensuring adequate compaction of the reinforced soil, proper connection of the geogrid to the facing system, and accurate placement of the geogrid layers are important considerations for the long-term stability of the reinforced slope in seismic-prone areas.

- Q: How are geogrids used in road construction?

- Geogrids are used in road construction to improve the stability and strength of the road. They are placed between different layers of the road, such as the subgrade and the base course, to distribute the load and prevent the movement of soil particles. This helps to increase the road's durability, reduce deformation, and enhance its overall performance.

- Q: I am a site using two-way 80 plastic geogrid, the need to use U type nails specifications and prices? Consultation with the construction process, thank you.Correction: two-way 80 steel plastic geogrid.

- First, the construction steps1, the basement cleaning and compactionClear the surface of the original surface and exclude surface water, clear surface thickness of 30cm, clear the table after the impact roller compaction base, the compaction degree of not less than 93%.

- Q: Do geogrids provide long-term stability to slopes?

- Yes, geogrids provide long-term stability to slopes. Geogrids are highly effective in reinforcing slopes by providing additional strength and preventing soil movement. They improve soil stability, prevent erosion, and enhance the overall longevity of slopes.

- Q: Can geogrids be used in reinforcement of underground tunnels and caverns?

- Yes, geogrids can be used in the reinforcement of underground tunnels and caverns. Geogrids are commonly used in geotechnical engineering applications to improve soil stability and provide reinforcement. They can be installed as a reinforcement layer within the tunnel or cavern walls to enhance their structural integrity and prevent potential collapses or deformations. The geogrids act as a reinforcement material, distributing the loads and increasing the overall strength of the underground structures.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Soil Stabilisation Geogrids - Polyester Geogrid with PVC Coated Warp Knitted for Roadbed/Airport/Railway/Slope/Retaining

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords