Aluminum Foil Facing Single Sided Aluminium Foil Scrim Kraft Laminated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

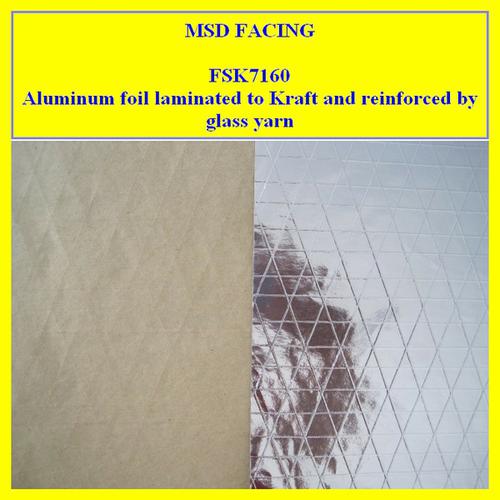

FSK7160 is the most popular laminated thermal insulation sheeting for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively, includes an reflective aluminum sheet and a fiberglass network disposed on and over a surface of the aluminum sheet

2. Construction & Benefits:

Reflective Aluminum Foil Lined With Kraft and Reinforced by fiberglass from 3 directions make this products durable.

Aluminum foil which is a good barrier to moisture, rust and the air, and friendly to environment, good conductivity from the aluminum layer eliminates the electrostatic effect easily as exposure and kraft being liner to rise the strength, they sandwiched together through polyethylene as adhesive.

l High performance cost ratio: reasonable price and professional service.

l Environment friendly: it does not contain any hazardous or harmful materials.

l Convenient to use, easy to be folded into various shapes according to actual needs.

l Better resistance and tenacity according to glass fiber within.

l Reduces heat loss in winter, heat gain in summer.

l Not effected by moisture and humidity.

l No special handling or breathing protection required.

3. Application:

It could be used as reflection, packing paper, moisture proof, radiant barrier and easy to fold as your need.

1. As a heat insulation materials in car, train, roof and wall, also been attached to glass wool blanket, rock wool board, mineral wool for get better performance.

2. A laminated thermal insulation sheeting. for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively.

3. As a sound absorber in KTV room, cinema, opera house, factory and other building.(only indicates 7160P, 7150P)

4. Package of industrial products and other place that you want to use.

4. Dimension/Size

(1) Roll width: 1000mm, 1200mm and 1250mm

(2) Roll Length: 50m, 100m, 200m, 500m, 1000m, or upon request.

(3) Core I. D.: 3"(76mm+/-1)

5. Similar products & guide

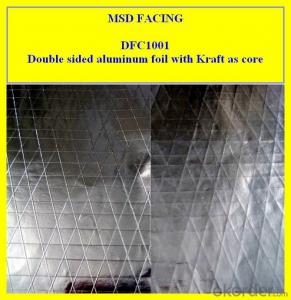

(1) DFC1001: Double sided aluminum foil supply better perfomance and function.

(2) FSK7160-P, perforate the FSK7160 as to absorb acoustic

(3) FSK7160-Tape: Applied pressure sensitive self adhesive and silicon coated paper to Kraft face, get the FSK TAPE

- Q: Is it possible to replace plastic wrap with aluminum foil for food storage or packaging purposes?

- <p>While aluminum foil facing can be used in some instances for food storage or packaging, it is not a direct substitute for plastic wrap. Aluminum foil is more durable and heat resistant, making it suitable for covering dishes or wrapping food for cooking or freezing. However, it is not as clingy or airtight as plastic wrap, which can be crucial for preserving freshness and preventing cross-contamination. Additionally, aluminum foil is not microwave-safe, unlike plastic wrap, which can limit its use in certain food storage applications. For best results, use the appropriate material based on the specific needs of food storage or packaging.</p>

- Q: What are the recommended cleaning products for aluminum foil facing after use?

- <p>For cleaning aluminum foil facing after use, it's best to use gentle, non-abrasive cleaning products. Mild dish soap and warm water are usually sufficient for most cleaning needs. Avoid using harsh chemicals or abrasive scrubbers, as they can damage the aluminum surface. If there are stubborn stains, a mixture of baking soda and water can be used as a gentle abrasive. Always rinse thoroughly and dry the surface to prevent any residue or potential damage.</p>

- Q: Is it possible to reuse the aluminum foil that was previously used on a surface?

- <p>Reusing aluminum foil facing can be tricky. If the foil is still in good condition without any tears or punctures, and it's clean, you might be able to reuse it for a similar application. However, it's important to note that the adhesive on the back of the foil can weaken over time and with use, which may affect its ability to stick properly. Additionally, if the foil has been exposed to high heat or has been used in a way that compromises its integrity, it's safer and more effective to replace it with new foil to ensure the best performance and avoid any potential hazards.</p>

- Q: What precautions should be taken when handling hot food using aluminum foil as a cooking tool?

- <p>When handling hot food using aluminum foil, first ensure the foil is thick enough to withstand high temperatures without puncturing. Always use heat-resistant gloves or a thick cloth to avoid burns. Do not wrap food directly in aluminum foil if it's very hot, as this can cause the foil to tear or the food to stick. Allow the food to cool slightly before wrapping. When removing the foil from the heat source, use tongs or a spatula to avoid direct contact with the hot foil. Be cautious of steam when opening the foil, as it can be very hot.</p>

- Q: Is it safe and practical to use recycled aluminum foil as a facing material in kitchen applications?

- <p>Yes, you can use recycled aluminum foil facing in your kitchen. Recycled aluminum is a sustainable and cost-effective material that retains the same properties as new aluminum. It is commonly used in kitchen applications such as backsplashes, countertops, and cabinetry due to its durability, low maintenance, and resistance to heat and moisture. However, ensure that the recycled aluminum foil facing is of high quality and meets safety standards to avoid any potential health or environmental concerns.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a sandwich?

- <p>Using aluminum foil facing to make a sandwich is not recommended. Aluminum foil is not designed for direct food contact, especially when heated, as it can leach aluminum into the food, which is potentially harmful. Instead, use materials specifically designed for food contact, such as wax paper, parchment paper, or plastic wrap, which are safe for contact with food and can withstand the temperatures involved in making a sandwich.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for transportation purposes?

- <p>Yes, you can use aluminum foil facing to wrap food for transporting. Aluminum foil is a common and safe material used for food packaging due to its ability to protect food from air, moisture, and bacteria. It also helps to maintain the temperature of the food, keeping it hot or cold as needed. However, ensure that the aluminum foil is food-grade and clean to prevent any contamination. Avoid using it in direct contact with acidic or salty foods as it may react and leach aluminum into the food, which is not recommended for consumption.</p>

- Q: Is it safe to use aluminum foil facing on lunch boxes for making sandwiches or wraps?

- <p>Yes, you can use aluminum foil facing to make sandwiches or wraps for lunch boxes. Aluminum foil is a common material used for food packaging due to its ability to keep food fresh and protected. It is non-toxic and does not react with most foods, making it safe for use in lunch boxes. However, it's important to ensure that the foil does not tear or come into direct contact with acidic foods, as this could potentially lead to the leaching of aluminum. Always handle food with clean hands or utensils to maintain hygiene.</p>

- Q: Is it safe to use old aluminum foil facing as a container for leftovers or dry goods?

- <p>While aluminum foil facing can be used as a temporary solution for storing leftovers or dry goods, it is not recommended for long-term storage. Aluminum foil facing may contain chemicals or coatings that are not food-safe, and it can also react with acidic or alkaline foods, potentially leaching harmful substances. For safe and long-lasting storage, it is best to use containers specifically designed for food storage, such as glass or food-grade plastic containers with airtight seals.</p>

- Q: This question asks for the optimal methods of storing food in containers not made of traditional food-safe materials.

- <p>The best ways to store food in containers made from alternative materials involve ensuring the containers are food-safe and do not impart any harmful substances to the food. For glass containers, ensure they are free of lead and are properly sealed to maintain freshness. For stainless steel containers, avoid those with non-food-grade coatings and ensure they are well-sealed to prevent spoilage. For silicone or plastic containers, look for BPA-free options and avoid high temperatures that could cause the material to leach chemicals. Always check for any odors or tastes that the container might impart to the food, and never store acidic foods in non-acid-resistant containers as this can lead to chemical reactions and contamination.</p>

Send your message to us

Aluminum Foil Facing Single Sided Aluminium Foil Scrim Kraft Laminated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords