Aluminum Foil Facing Foil Scrim Kraft Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

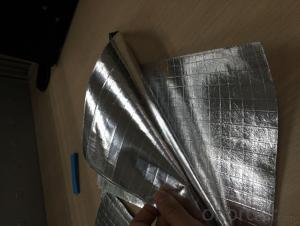

FSK7160 is the most popular laminated thermal insulation sheeting for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively, includes an reflective aluminum sheet and a fiberglass network disposed on and over a surface of the aluminum sheet

2. Construction & Benefits:

Reflective Aluminum Foil Lined With Kraft and Reinforced by fiberglass from 3 directions make this products durable.

Aluminum foil which is a good barrier to moisture, rust and the air, and friendly to environment, good conductivity from the aluminum layer eliminates the electrostatic effect easily as exposure and kraft being liner to rise the strength, they sandwiched together through polyethylene as adhesive.

l High performance cost ratio: reasonable price and professional service.

l Environment friendly: it does not contain any hazardous or harmful materials.

l Convenient to use, easy to be folded into various shapes according to actual needs.

l Better resistance and tenacity according to glass fiber within.

l Reduces heat loss in winter, heat gain in summer.

l Not effected by moisture and humidity.

l No special handling or breathing protection required.

3. Application:

It could be used as reflection, packing paper, moisture proof, radiant barrier and easy to fold as your need.

1. As a heat insulation materials in car, train, roof and wall, also been attached to glass wool blanket, rock wool board, mineral wool for get better performance.

2. A laminated thermal insulation sheeting. for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively.

3. As a sound absorber in KTV room, cinema, opera house, factory and other building.(only indicates 7160P, 7150P)

4. Package of industrial products and other place that you want to use.

4. Dimension/Size

(1) Roll width: 1000mm, 1200mm and 1250mm

(2) Roll Length: 50m, 100m, 200m, 500m, 1000m, or upon request.

(3) Core I. D.: 3"(76mm+/-1)

5. Similar products & guide

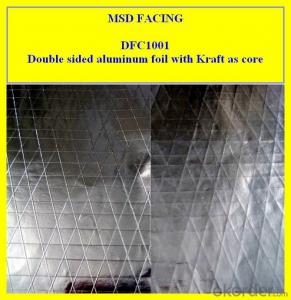

(1) DFC1001: Double sided aluminum foil supply better perfomance and function.

(2) FSK7160-P, perforate the FSK7160 as to absorb acoustic

- Q: What are the methods to prevent grease stains on aluminum foil after using it for cooking?

- <p>To avoid grease stains on your aluminum foil facing after cooking, consider the following tips: Use a double layer of foil to increase protection, ensuring the foil is large enough to fully cover the cooking surface. Preheat your foil before placing it on the cooking surface to reduce the chance of grease sticking. Clean the foil immediately after use with warm soapy water to remove any grease before it sets. Alternatively, you can use non-stick spray or a light coating of oil on the foil before using it, which can help prevent grease from adhering.</p>

- Q: What distinguishes various grades of aluminum foil sheets from one another?

- <p>Different grades of aluminum foil sheets are distinguished by their thickness, strength, and purity. Grade 1 is the purest and softest, used for food wrapping and baking. Grade 2 is harder and more tear-resistant, suitable for heavy-duty use like grilling. Grade 3 is an alloy and offers high strength and durability, often used in industrial applications. Grade 4 is a heat-treatable alloy, providing high strength and used in aerospace and automotive industries. Each grade has specific applications based on its unique properties.</p>

- Q: This question asks for instructions on how to use aluminum foil as a wrapping material for food.

- <p>To use aluminum foil facing to wrap food, first ensure the foil is clean and free of tears. Cut a piece of foil large enough to fully cover the food item. Place the food in the center of the foil. Bring up the sides of the foil and fold them over the food, sealing the edges tightly to prevent air and moisture from entering. For more secure wrapping, double fold the edges or use a crimping technique. For items like fish or meat, you can also create a sealed pouch by folding the foil over the food, then folding the edges inward and crimping to close. Always handle food with clean hands or utensils to maintain hygiene.</p>

- Q: What are the safety regulations or guidelines that aluminum foil facing must adhere to?

- <p>Safety standards for aluminum foil facing are crucial to ensure the product's safety and effectiveness. These standards typically include requirements for material composition, thickness, and bonding strength to ensure the foil's durability and resistance to tearing. Additionally, there are guidelines for the foil's reflectivity and heat resistance, which are important for its performance in various applications. Compliance with these standards is often verified through testing and certification processes, ensuring that aluminum foil facing products meet the necessary quality and safety benchmarks before they reach the market.</p>

- Q: What are the unique considerations or guidelines for storing food using food wrap materials?

- <p>When storing food wrapped in food wrap materials, it's crucial to ensure that the food is properly sealed to maintain freshness and prevent contamination. Always wash your hands and the food items before wrapping. Keep perishable foods refrigerated, ideally below 40掳F (4掳C), and use the food within the recommended time frame to avoid spoilage. Avoid wrapping hot foods directly as it can damage the wrap and potentially contaminate the food. Store wrapped foods in a clean environment and away from direct sunlight or heat sources to prevent the wrap from melting or the food from spoiling.</p>

- Q: Is it possible to use aluminum foil with a shiny side as a non-stick surface for cooking purposes?

- <p>Yes, you can use aluminum foil facing as a non-stick surface for cooking. The shiny side of aluminum foil is often used to create a non-stick surface, which can be helpful when grilling or baking to prevent food from sticking to the pan or grill. However, it's important to use it properly to avoid any potential health risks. Ensure that the foil doesn't touch the heat source directly for extended periods, as this can cause the foil to break down and release aluminum into the food. It's also recommended to use heavy-duty aluminum foil for cooking to ensure it can withstand higher temperatures without puncturing or melting.</p>

- Q: This question asks for the method to wrap a hot pan using aluminum foil, with specific instructions on how the foil should face.

- <p>To wrap a hot pan with aluminum foil, first ensure the pan is stable and on a heat-resistant surface. Take a large piece of aluminum foil, about twice the size of the pan. Hold one corner of the foil and drape it over the pan, allowing the shiny side to face the pan. Gently press the foil against the pan, working your way around the edges to cover the entire surface. Ensure the foil is snug but not too tight to avoid tearing. The shiny side facing the pan will help reflect heat and protect the pan's surface. Be cautious while handling the hot pan and aluminum foil to avoid burns.</p>

- Q: This question asks about the various types of aluminum foil facing that can be found in the market.

- <p>Aluminum foil facing is commonly used in construction for insulation and moisture protection. The different types available on the market include: 1) Plain Foil Facing, which is a simple, smooth aluminum surface; 2) Embossed Foil Facing, featuring a textured pattern for added strength; 3) Reinforced Foil Facing, which incorporates additional materials for enhanced durability; 4) Coated Foil Facing, where the aluminum is coated with other substances to improve performance; and 5) Laminated Foil Facing, which combines aluminum with other materials for specific applications. Each type serves different purposes and has unique properties that cater to various construction and industrial needs.</p>

- Q: Describe the most effective method for cleaning aluminum foil facing surfaces after they have been used.

- <p>The best way to clean aluminum foil facing after use is to gently wipe it with a soft, damp cloth to remove any residue or food particles. Avoid using abrasive materials or harsh chemicals, as they can scratch the surface. If there is stubborn residue, a mild dish soap can be used with warm water. After cleaning, dry the surface thoroughly to prevent water spots and potential damage. Regular cleaning helps maintain the appearance and functionality of the aluminum foil facing.</p>

- Q: Is it possible to use aluminum foil facing in the creation of desserts?

- <p>Yes, aluminum foil facing can be used for making desserts, particularly for baking purposes. It is often used to line baking sheets or molds to prevent desserts from sticking, making them easier to remove after baking. It also helps in maintaining the shape and presentation of the dessert. However, it's important to ensure that the foil does not come into direct contact with the dessert if it's not oven-safe, as this could lead to contamination or uneven cooking. Always follow the manufacturer's guidelines for the specific type of aluminum foil you are using.</p>

Send your message to us

Aluminum Foil Facing Foil Scrim Kraft Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords