Aluminum Window Profiles - Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

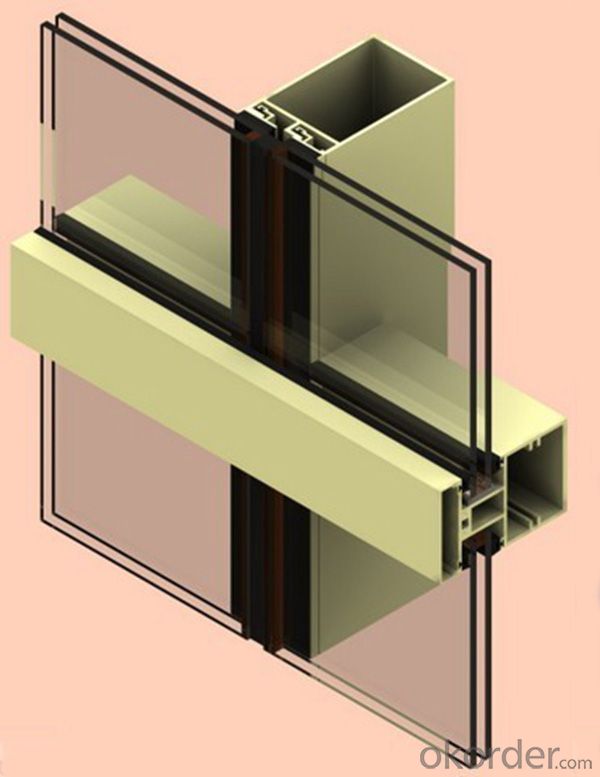

5. Image of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

6. Package and shipping of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: What is the aluminum section table?

- Table characteristics: working table, using aluminum material customized special products and durable, the breakage rate of the lowest! For quality of aluminum profiles, I strongly recommend item aluminum, aluminum fortunately which do not know, do not know how the quality of aluminum is our common problem. Here is a little experience for me to share with you.

- Q: Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can definitely be used for modular storage systems. Aluminum is a lightweight yet sturdy material that is commonly used in various industries for its durability and versatility. It is particularly well-suited for modular storage systems due to its ability to be easily cut, shaped, and joined together. Aluminum profiles provide a great solution for creating customized storage units that can be easily adjusted or expanded as needed. They can be used to build shelving systems, cabinets, drawers, and other storage components. The modular design allows for easy assembly and disassembly, making it convenient to rearrange or reconfigure the storage system whenever required. Furthermore, aluminum profiles offer excellent corrosion resistance, ensuring that the storage system will remain in good condition even in harsh environments. They are also available in a variety of finishes, allowing for customization to match the desired aesthetic or design requirements. Overall, aluminum profiles provide a cost-effective and durable solution for modular storage systems, offering flexibility, ease of use, and long-lasting performance.

- Q: Are aluminum profiles suitable for roofing systems that need to withstand strong wind loads?

- <p>Yes, aluminum profiles can be used for roofing systems that require high levels of wind load resistance. Aluminum is a lightweight yet strong material with excellent resistance to corrosion and weathering. It can be engineered into profiles that provide the necessary structural integrity to withstand high wind loads. The flexibility of aluminum allows for the creation of various shapes and designs that can be tailored to meet specific wind resistance requirements. Additionally, aluminum's durability and low maintenance make it a popular choice for roofing systems in areas prone to high winds.</p>

- Q: What are the ten brands of aluminum alloy profiles?

- Top ten list of Chinese aluminum profiles Enterprises1 、 aluminum material(China Aluminum Group, China's top ten aluminum enterprises, central management of large state-owned enterprises)2 - Asia - South Asia(China famous trademark, China famous brand, China aluminum profile enterprise ten, Guangdong Asia Aluminum Factory Co., Ltd.)3, the United States and aluminum(A Well-Known Trademark in China, China brand, China aluminum enterprise ten, Guangdong Jianmei Aluminum Profile Factory Co., Ltd.)4, South South aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong south south Aluminum Industry Co., Ltd.)5, Zhong Wang aluminum(China famous brand, China famous brand, Liaoning famous brand product, China Zhong Wang Holdings Limited)6, Hing Fat aluminum(China brand, A Well-Known Trademark in China, China aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7, pillars of aluminum(listed companies, Chinese famous brands, China's well-known trademarks, China's aluminum enterprises ten, Zhejiang pillars, new materials, Limited by Share Ltd)8 、 Nanshan aluminum material(China famous brand, China well-known trademark, ten aluminum profile enterprises in China, Shandong Nanshan aluminum & Limited by Share Ltd)9, the court aluminum profiles(China's well known trademark, China's top ten aluminum enterprises, Polytron Technologies Inc, Shanghai aluminum Fair)10, Albert aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong Weiye aluminium factory Co., Ltd.)

- Q: This question asks for an overview of the various types of fasteners that can be used in conjunction with aluminum profiles.

- <p>Aluminum profiles are commonly used in construction and manufacturing, and they require fasteners for assembly. The different types of fasteners include: 1. T-nuts and T-bolts: These are used for creating strong connections within the profile. 2. Clamping blocks: These are used to secure profiles together without the need for drilling. 3. Corner brackets: These are used to create 90-degree connections between profiles. 4. Angle brackets: Similar to corner brackets but for creating angled connections. 5. End caps: These are used to cover the ends of profiles for a finished look. 6. Dowels: These are used for aligning and joining profiles together. 7. Screws and bolts: These are used for securing components to the profiles. Each type of fastener serves a specific purpose and is chosen based on the particular application and design requirements.</p>

- Q: Can aluminum profiles be used in railway and transportation infrastructure?

- Yes, aluminum profiles can be used in railway and transportation infrastructure. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and easy fabrication. It can be used in the construction of train bodies, windows, doors, and various structural components. Additionally, aluminum profiles are recyclable, making them environmentally friendly and cost-effective for transportation projects.

- Q: What are the potential effects on the environment when aluminum profiles are used in the construction of buildings?

- <p>The use of aluminum profiles in building construction has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, which reduces the energy required for transportation and can contribute to a building's energy efficiency. It is also recyclable, with a high recycling rate, which helps to conserve resources and reduce waste. However, the production of aluminum is energy-intensive and generates greenhouse gas emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The environmental impact of using aluminum profiles in construction must therefore be balanced against these factors.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are frequently utilized in the field of commercial construction.

- <p>Commonly used aluminum profiles in commercial construction include: 1. Extruded aluminum profiles, which are versatile and can be customized for various applications. 2. Structural aluminum framing, used for building structures and curtain walls. 3. Aluminum window and door frames, known for their durability and energy efficiency. 4. Aluminum handrails and railings, important for safety in commercial buildings. 5. Aluminum trusses, used for roof structures and large spans. 6. Aluminum angles and channels, used for support and framing. 7. Aluminum tubes, used in various structural and decorative applications. These profiles are chosen for their strength, lightweight, corrosion resistance, and ease of maintenance.</p>

- Q: This question asks about the typical applications of aluminum profiles within the field of architectural design.

- <p>Aluminum profiles are commonly used in building design for various structural and aesthetic purposes. They are utilized in curtain walls, window frames, and door systems for their strength and lightweight properties. Additionally, aluminum profiles are employed in the construction of balconies, handrails, and sunshades due to their durability and resistance to corrosion. They are also used in interior design for creating partition walls, ceiling systems, and decorative elements. The versatility of aluminum profiles allows them to be easily adapted to different architectural styles and requirements, making them a popular choice in modern construction.</p>

- Q: Can aluminum profiles be used in the production of medical devices?

- Yes, aluminum profiles can be used in the production of medical devices. Aluminum is a lightweight and corrosion-resistant material that offers several advantages for medical applications. It can be easily machined, formed, and welded into various shapes and sizes, making it suitable for creating precise and complex components required in medical devices. Aluminum profiles also have excellent conductivity properties, which is essential for devices that require electrical connections. Additionally, aluminum is non-toxic, non-magnetic, and does not release harmful substances, making it safe for use in medical settings. It is widely used in the production of medical devices such as surgical instruments, hospital bed frames, wheelchair components, IV stands, and many others.

Send your message to us

Aluminum Window Profiles - Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords