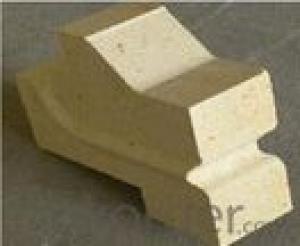

Silica Fire Bricks for Hot Blast Stove

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.High refractoriness under load.

2.High heat conductivity.

3.Good thermal shock resistance.

4.Solidity stable of capacity

Typical Features:

1.High refractoriness under load.

2.High heat conductivity.

3.Good thermal shock resistance.

4.Solidity stable of capacity

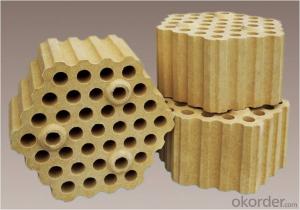

Applications:

1.Silica brick is the main refractory bricks used in glass melting furnace;It has high refractoriness

2.Silica brick for glass melting furnace is used in building checker chamber, chute, combustion chamber,coking 3.chamber,and furnace arch etc.

4.Silica bricks and fireclay bricks are all acid-resistant bricks.They can be used for glass furnace and other acid

industrial furnace.

Specification:

Item /Specification | High quality silica brick |

SiO2 % ≥ | 94 |

Fe2O3% ≤ | 1.0 |

Meltability Index% ≤ | 1.0 |

True Density g/cm3 ≤ | 2.36 |

Refractoriness°C≥ | 1730 |

refractoriness under load ≥°C | 1650 |

Apparent Porosity%≤ | 25 |

Cold crushing strength ≥Mpa | 25 |

Reheating Linear Change1450°C×.2h ≤% | +0.2 |

Packaging & Delivery

| Packaging Detail: | in plastic sheets and then in wooden pallets |

| Delivery Detail: | about 30 days or as your requirement |

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Classification of chemical components of refractory materialsAccording to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Heating calcination is the best way to extend this sort of impurity removal. Remove impurities

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: The chemical composition of silica brick and its physicochemical index?

- Brick refers to the refractory products in more than 93% of the content of SiO2

- Q: Why in the production of the brick to detect the volume density

- Product quality control of silica brick.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

Send your message to us

Silica Fire Bricks for Hot Blast Stove

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords