Silica Silicate Mullite Bricks for Induction Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

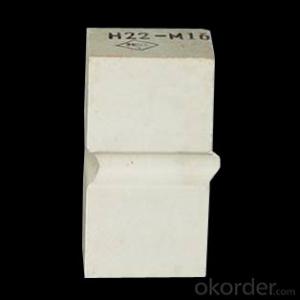

Silicate Mullite Bricks for Induction Furnace

Brief discription for Silicate Mullite Bricks

CMAX Silicate Mullite Bricks are classified according to alumina content ranging from 48% to 90%.

CMAX Silicate Mullite Bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Silicate Mullite Bricks for Induction Furnace

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Acidic materialMainly siliceous materials, such as quartz, tridymite and cristobalite, chalcedony, flint, opal, white quartzite, silica sand, diatomaceous earth, silicon oxide contained in these siliceous materials (SiO2) at least 90%, pure raw materials are silicon oxide as high as 99% or more. Siliceous materials at high temperature is the acidic nature of chemical dynamics, when the presence of metal oxide, or when in contact with the chemical reaction, and combined with a fusible silicate. Therefore, if there is a small amount of metal oxide in siliceous material, it will seriously affect its thermal resistance.

- Q: What role does silica play in refractories?

- The production of clay brick refractory clay raw material is natural, its main mineral is kaolinite (formula Al2O3 - 2SiO2 - 2H2O), clay brick containing SiO2 in 45% ~ 65%, belongs to the weak acid refractory materials, have a certain ability to resist acid slag, but easy to be alkaline slag erosion.

- Q: The brick is mainly used in the place?

- Open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts.

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: The chemical composition of silica brick and its physicochemical index?

- Brick refers to the refractory products in more than 93% of the content of SiO2

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: The formula in the refractory brick, and firing curve, who knows?

- By silica powder, 81-85%, perlite 15-19%, plus the total weight of the main raw materials of the following accessories

Send your message to us

Silica Silicate Mullite Bricks for Induction Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches