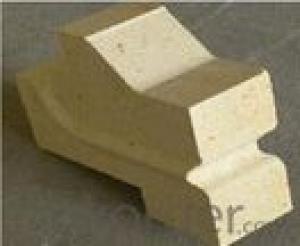

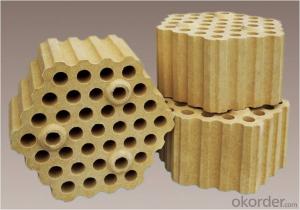

Silica Brick for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Characteristic:

1.High refractoriness under load

2.High temperature resistance

3.Corrosion resistance

Product Description

| Item | Coke Oven Silica Brick | Glass Furnace Silica Brick | Hot Blast Stove Silica Brick | |

| JJG-94 | JBG-95 | JBG-96 | JRG-95 | |

| SiO2 % | 94.5 | ≥95 | ≥96 | 95 |

| Fe2O3 % | 1.5 | ≤1.0 | ≤1.0 | 1.3 |

| CaO % | 2.5 | 2.2 | 2.2 | |

| Al2O3+Na2O+K2O % | ≤0.5 | ≤0.5 | 1 | |

| Refractoriness °C | 1710 | 1710 | 1710 | 1710 |

| Refractoriness under load T1,°C | 1650 | 1650 | 1660 | 1650 |

| Apparent porosity % | 22(24) | 22(24) | 22(24) | 22(24) |

| Cold crushing strength Mpa | 40(35) | 35(30) | 35(30) | 35(30) |

| True Density g/cm3 | 2.33 | 2.32 | 2.33 | 2.34 |

| Thermal Expansion % | 1000°C 1.28(1.30) | 1000°C ≤1.25 | 1000°C ≤1.25 | 1000°C 1.26 |

| Residual Quartz % | 1.0 | 1.0 | 1.0 | 1.0 |

| Creep rate % | 1550°C×50h(0.8) | |||

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: Semisilica brick interpretation

- High temperature volume stability. Volume change is small.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into phosphorus and quartz. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Which material is good for furnace refractory?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick with chromium oxide as its main component has good corrosion resistance, but its thermal shock resistance is poor, and its deformation temperature is lower at high temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, good thermal shock resistance, high strength, resistance to acid and salt corrosion, especially weak acid has good resistance, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Heating calcination is the best way to extend this sort of impurity removal. Remove impurities

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- The content of SiO2 is 98.23% crystalline silica as raw material, with sulfite pulp liquid as binder, millscale and lime as mineralizer, by Jin Hongshi (TiO2) as additive, can improve the rate of thermal conductivity of silica brick for coke oven. When the rutile content is 1.5%, the coefficient of thermal conductivity of silica brick for coke oven is 2.66W/ (m.k).

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Brick for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords