Silica Brick for High Duty Ceramic Firing Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

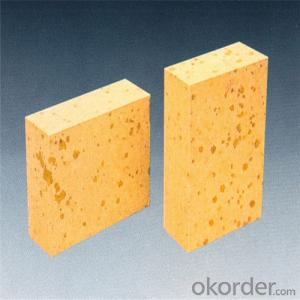

Ceramic firing kiln refractory Silica Brick Description:

Refractory Silica Brick is mainly made of top class silica, via shaping and burning under the high temperature,

Possesses high temperature resistant, high strength and low impurities, etc.

It is mainly used for blast furnaces and hot blast stove.

Features

Ceramic firing kiln refractory Silica Brick Advantage:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point

Applications:

Light weight silica bricks are primarily used for furnaces and kilns in metallurgy, steel, power, chemical industry, and electric power and machine building etc areas

Ceramic firing kiln refractory Silica Brick specifications:

Product | AZM-1550 | AZM-1650 | AZM-1680 | |

Index | Index | Index | Index | |

chemical composition | SiC+SiO2 | ≥35 | ≥30 | ≥32 |

Al2O3 | ≥60 | ≥65 | ≥65 | |

Bulk Density(g/cm3) | ≥2.55 | ≥2.65 | ≥2.70 | |

Apparent Porosity (%) | ≤20 | ≤19 | ≤19 | |

Cold Crushing Strength(Mpa) | ≥80 | ≥90 | ≥100 | |

Refractoriness Under Load | ≥1550 | ≥1650 | ≥1680 | |

Thermal Shock Resistance | ≥10 | ≥15 | ≥20 | |

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Classification of chemical components of refractory materialsAccording to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: How much is the highest melting point of silicon?

- . True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. The total volume of heating to 1450 DEG about 1.5~2.2% expansion, the residual expansion will make cutting seam sealing, ensure masonry tightness and good structure strength, so that the brick load softening temperature will reach 1750 degrees Celsius above 1620 degrees in the case of the highest melting point.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: The brick is mainly used in the place?

- Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use, but the anti alkali erosion ability, thermal shock stability is the worst, a scrap. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick for High Duty Ceramic Firing Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords