Silica Brick for Hot Blast Stove/Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

Modern hot stoves hot blast average temperature is up to 1,250 ℃- 1,300 ℃, so there are higher requirements on refractories quality, like checker chamber upper area, combustion chamber where are key areas for stoves campaign life. Therefore, some clients and experts have proposed the goal that campaign life of hot stoves should be twice as much as the life of blast furnace. Obviously, this is a challenge to refractories quality. It has become an important task for the refractory industry to select one kind of refractory with good thermal stability, high resistance to high temperature compression creep, high refractoriness under load and reasonable price to use in the hot stove with high blast temperature. The excellent performance silica brick has the following characteristics. The low creep, high refractories under load and low residual quartz contents, silicon bricks for hot stove of our company has been successfully applied to various types of hot stoves of major steel companies at home and abroad and the quality has been recognized by the clients.

Feature

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Technical Data

| Brand Item | CGZ-95 | CRG-95 | CJG-94 | ||

| Dome & Wall brick | Checker | Sole & wall brick | Others | ||

| Refractoriness º C ≥ | 1710 | ||||

| Permanent liner change 1450 º C × 2h % | +0.2 0 | ||||

| Apparent Porosity (%) ≤ | 22 | 22 | 23 | 22 | 24 |

| True Density (g/cm3) ≤ | 2.37 | 2.35 | 2.35 | 2.34 | 2.35 |

| Cold Crush Strength (MPa) ≥ | 29.4 | 35 | 30 | 30 | 25 |

| Thermal Expansion(1000 º C ) % | 1.26 | 1.26 | 1.28 | 1.30 | |

| Refractoriness under Load 0.2MPa Ta( º C ) ≥ | 1650 | 1650 | 1650 | ||

| Chemical analysis SiO 2 % ≥ | 95 | 95 | 95 | 94 | 94 |

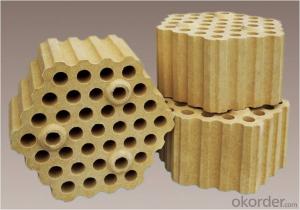

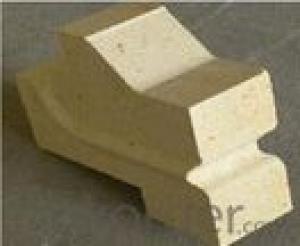

Photos for Applications

- Q: The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- The ability of alkali resistance is poor, the thermal shock stability is the worst, and it is scrapped at one time. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick products according to the standard JC/T615-1996, the single brick is divided into 3 grades: XBG-96, ZBG-96, DBG-96.

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: What role does silica play in refractories?

- The natural mineral of silica is called quartz. In refractories, silica and siliceous refractory materials contain more silica. Silica is acidic at high temperature, and siliceous refractory can resist acid slag corrosion

- Q: What is the silica refractory products?

- Refractory brick with silica content greater than 90%.

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

- Q: Physical solid waste disposal

- Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products when firing, reduce cracks, improve the rate of finished products.

Send your message to us

Silica Brick for Hot Blast Stove/Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords