Silica Mullite Wear Resistant Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

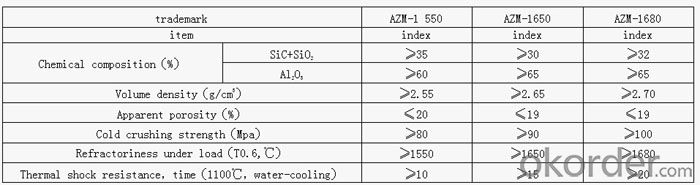

Features: High crushing strength, high hot strength, good thermal shock resistance, continuously forming protective layer during service, good wear resistance, strong anti-stripping resistance.

Applications: transitional zone, kiln mouth, tertiary air duct, decomposing furnace of cement kiln.

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: The chemical composition of silica brick and its physicochemical index?

- Brick refers to the refractory products in more than 93% of the content of SiO2

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Iron scale powder 0.45-0.55%, cement 0.9-1.1%, lime milk 6.5-7.5%, pulp 1.95-2.2%, the silica powder, perlite will be added to the wet mill in proportion, and then add iron scale powder, cement, dry roller 1-2 minutes later

Send your message to us

Silica Mullite Wear Resistant Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords