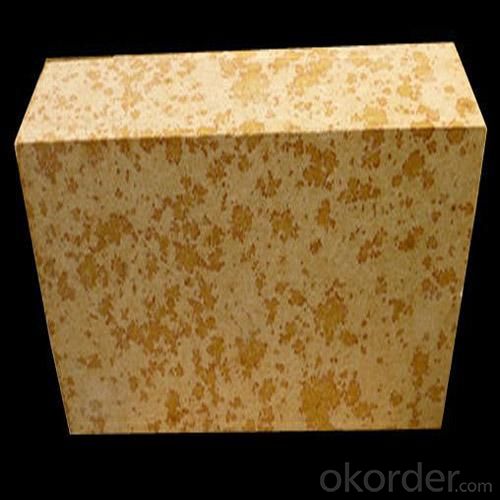

Silica Brick S95B for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t.

- Supply Capability:

- 1000 Tons Per Mon m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Silica Brick For Hot Blast Stove---S95B

Our corporation produces a comprehensive range of silica bricks, with high silica content, all of these bricks exhibit excellent performance.

Our Silica bricks are the final result of blending excellent tridymite and cristobalite, as the main raw materials with cutting-edge technology, after mixing, drying, forming, in the high temperature shuttle kiln. There are also little quartz and vitreous within. We ensure you that the silica bricks made by us possess high quality standard and have gone through all the complicated quality control parameters. Their durability and strength adds life to the structure and they have the capacity of bearing high temperature.

Silica Brick For Hot Blast Stove---S95B | ||

Physical Properties: |

|

|

Permanent Linear Change(1500℃×4h)% | % | ±0.2 |

Apparent Porosity, % | % | ≤23 |

Cold Crushing Strength | Mpa | 29.4 |

Refractoriness Under Load (T0.6) | ℃ | ≥1600 |

Thermal Expansion | % | ≤1.3 |

Density | g/cm3 | ≥2.35 |

Chemical Analysis: |

|

|

SiO2 | % | ≥95 |

Fe2O3 | % | ≤0.5 |

Al2O3 | % | ≤0.8 |

Residual Quartz | % | ≤1 |

Note: | ||

Feature of Silica Brick For Hot Blast Stove---S95B

Resistant to thermal shock, abrasion, chemical attack

High ability for anti-abrasion during work

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Applications of Silica Brick For Hot Blast Stove---S95B

Silica brick for Hot Blast Stove is mainly used in hot-Blast Stove.

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on. The properties and process of silica crystal with SiO2 transformation is closely related, therefore, the proportion of it is one of the important quality indexes of silica brick. General requirements below 2.38, high quality silica brick should be less than 2.35. The true density is small, reflecting a large number of scale quartz and square quartz in the brick, the residual quartz is small, so the residual line expansion is small, and the strength is decreased in useThe raw materials for the manufacture of silica brick. The higher the SiO2 content of silica raw material, the higher the refractoriness. The most harmful impurities are Al2O3, K2O, Na2O and so on. They seriously reduce the refractoriness of refractory products. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer (e.g. millscale, lime) and binder (such as molasses, sulfite pulp waste liquid), after mixing, molding, drying, sintering and other processes in the system.

- Q: How much is the highest melting point of silicon?

- Acidic silica brick refractories, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. More than 94% silica content.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: The formula in the refractory brick, and firing curve, who knows?

- By silica powder, 81-85%, perlite 15-19%, plus the total weight of the main raw materials of the following accessories

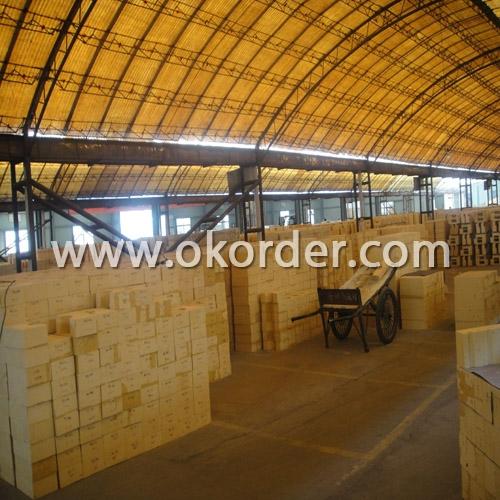

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Silica Brick S95B for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t.

- Supply Capability:

- 1000 Tons Per Mon m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords