Geotextil 2500 Short/Long Fiber Needle Punched Non Woven Geotextile (PP PET) for Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

Good tenacity, high density, loose structure, anti-corrosion, anti-aging, acid-and-alkali-resistance, good water absorption and permeability, high tensile strength, strong anti-deformation, filtering and isolation performance, operability for construction.

Main Features of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

1. Filtration:

Used as the reversed filter to both prevent sand particulate from passing through and to allow free-flow for water and air.

2.Isolation:

Serving as isolation between ballast and subgrade or subgrade and soft ground in railway, surface course and subgrade or between different dam material in the airport and parking area, to isolate sand, stone in various diameter size from subgrade or other buildings.

3.Reinforcing: Used in engineering of road, railway, earth-rock dam, breakwater, airport, revetment refilling soil, slope and etc, to distribute soil body stress, prevent lateral soil movement and increase stability of soil.

4.Protection:

Used to prevent from scour by wind, wave, tide and/or rain and to protect bank and bottom, to avoid loss of soil and water

Surface Effects of Short Fiber Needle Punched Non-woven Geotextile:

Needle-punched, hot rolled (on single or both sides), jenappe, gum dipping (single or both sides)

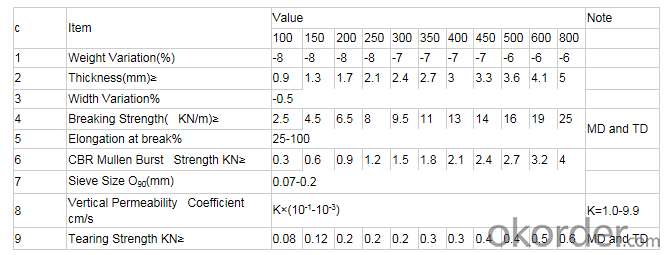

Specifications of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

Short fiber nonwoven geotextile technical data

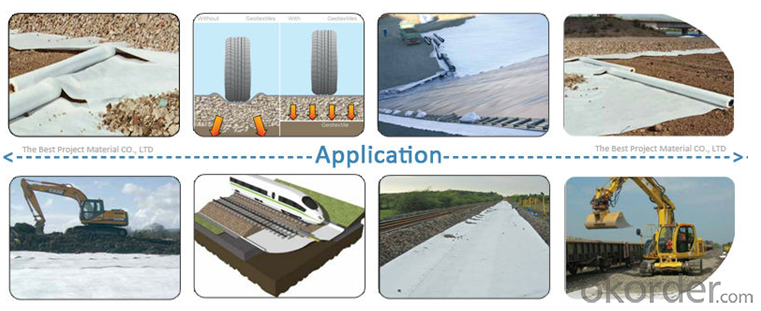

Applications of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

Used in many civil engineering and building applications. Designed to offer filtration, separation, and ersion control functions.

Application industry

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

IMages of Short/long Fiber Needle Punched Non Woven Geotextile (PP PET):

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can geotextiles be used in mining tailings management?

- Yes, geotextiles can be used in mining tailings management. Geotextiles are commonly used in mining operations to provide stability and containment for tailings, which are the waste materials left over after the desired minerals have been extracted. They can be used to line tailings storage facilities, prevent erosion, control water flow, and promote soil filtration, thus enhancing the overall management and mitigation of mining tailings.

- Q: What are the factors to consider when selecting geotextiles for landfill applications?

- When selecting geotextiles for landfill applications, there are several factors to consider. These include the type and strength of the geotextile, its permeability and filtration properties, its resistance to chemical and biological degradation, its durability and longevity, as well as its cost-effectiveness. It is important to choose a geotextile that can effectively separate different materials in the landfill, provide adequate drainage and filtration, withstand the harsh environmental conditions, and ultimately contribute to the overall stability and performance of the landfill system.

- Q: What are the key considerations for geotextile installation in high-altitude regions?

- The key considerations for geotextile installation in high-altitude regions include the selection of materials that can withstand extreme weather conditions, such as low temperatures and high winds. It is important to choose geotextiles with high tensile strength and durability to ensure they can withstand the harsh environment. Additionally, proper anchoring techniques and installation methods should be employed to ensure the geotextiles remain in place and perform their intended functions effectively.

- Q: Can geotextiles be used in the construction of artificial ponds?

- Yes, geotextiles can be used in the construction of artificial ponds. They are commonly used as a lining material to prevent soil erosion, filter water, and provide stability to the pond's structure. Geotextiles help to retain water and create a durable barrier that prevents leakage in the pond.

- Q: Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. They are commonly used in civil engineering projects to reinforce soils, prevent erosion, and improve the overall stability of the soil. Geotextiles can effectively distribute loads, control soil movement, and enhance the performance of the soil in various applications such as road construction, retaining walls, slopes, and landfills.

- Q: How do geotextiles help with load distribution in pavement systems?

- Geotextiles provide a reinforcing and stabilizing function in pavement systems by distributing applied loads more evenly across the underlying soil, reducing stress concentrations, and preventing the formation of cracks and deformations.

- Q: How do geotextiles help with vegetation establishment?

- Geotextiles help with vegetation establishment by providing a stable and favorable environment for plant growth. They prevent erosion by holding soil in place, allowing roots to establish and anchor the vegetation. Geotextiles also retain moisture and regulate soil temperature, promoting optimal conditions for seed germination and plant growth. Additionally, they protect young plants from weed competition, herbicide leaching, and wildlife damage, ultimately enhancing the success of vegetation establishment.

- Q: Composite geotextile plastic composite

- 1, plastic composite geotextile is woven with a woven fabric as the substrate, the extruded coated polyolefin resin film or polyolefin resin sandwich layer, the woven cloth and all kinds of Zhang made together. 2, the product made of bags with light weight, acid and alkali resistance, strength, moisture and other advantages. 3, widely used in chemical fertilizer, synthetic resin, coarse salt, ore and cement products such as packaging, is a good packaging of heavy packaging materials

- Q: Are geotextiles effective in preventing soil erosion?

- Yes, geotextiles are effective in preventing soil erosion. They act as a barrier that prevents soil particles from being carried away by water or wind, while still allowing water to pass through. This helps to stabilize the soil and reduce erosion, making geotextiles a valuable tool in erosion control measures.

- Q: How do geotextiles improve the performance of geomembranes?

- Geotextiles improve the performance of geomembranes by acting as a protective barrier that prevents direct contact with the underlying soil or other abrasive materials, thereby reducing the risk of punctures or damage. They also provide additional reinforcement and stability, distributing loads more evenly across the geomembrane. Additionally, geotextiles allow for better water drainage and filtration, preventing the accumulation of water pressure and enhancing the overall performance and longevity of the geomembrane system.

Send your message to us

Geotextil 2500 Short/Long Fiber Needle Punched Non Woven Geotextile (PP PET) for Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords