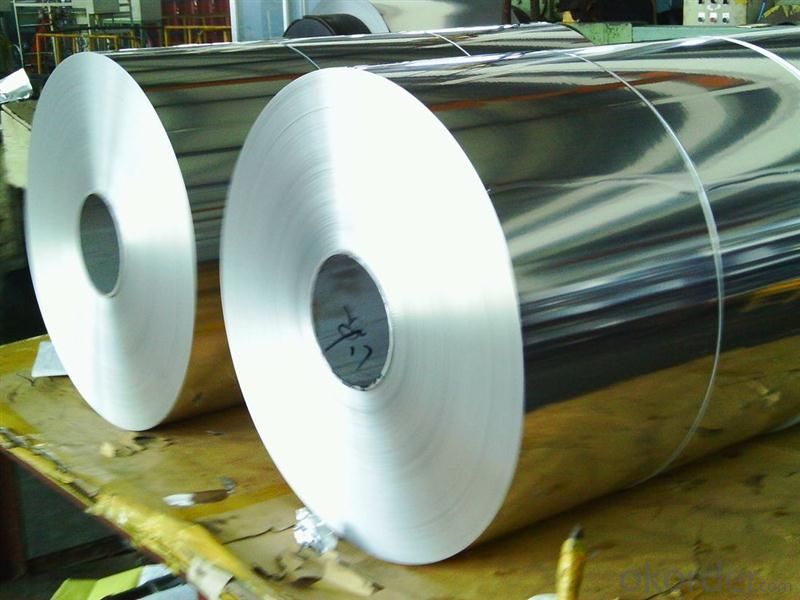

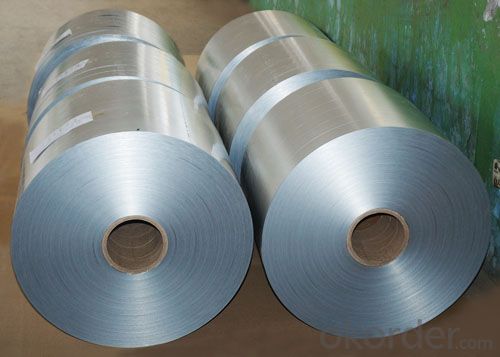

Sheet Aluminum Coil 1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: when ferrous sulfate is poured into an aluminium can, holes appear in the can. Why?

- aluminum reacts via a redox reaction with iron(II): 3 Fe2+(aq) + 2 Al(s) --- 3 Fe(s) + 2 Al3+(aq)

- Q: I take an extracurricular aircraft class, and I got the okay to take some old painted sheet aluminum for another project I'm working on. The problem is, what I'm using it for I need bare aluminum. I heard around that air crafts are painted with something that regular (store-bought) paint stripper can't remove. Is this true? I am aware of the fact that stripping something like that will result in a toxic paint sludge, so I've taken precautions for that. I just need to know if heavy-duty paint stripper from Home Depot will do the job. Thanks :)

- It depends on how old the paint is. If your panel was painted before the 1970's, then pretty much any chemical paint stripper will work. After the 70's, they started using epoxy based primers and paints and those are more resistant to chemical strippers. In any case, wear rubber gloves and breathing protection while using chemical paint strippers. They can burn your skin and create toxic fumes when in use.

- Q: What are the different types of aluminum coils available?

- There are several types of aluminum coils available, including painted coils, embossed coils, brushed coils, anodized coils, and perforated coils. Each type offers unique characteristics and applications, catering to various industries and aesthetic preferences.

- Q: How are aluminum coils tested for flatness?

- Various methods are employed to test the flatness of aluminum coils, guaranteeing their compliance with the necessary standards. One commonly used approach involves the utilization of a straight edge. In this method, a lengthy and meticulously precise straight edge is placed on the coil's surface. Technicians then visually inspect for any discrepancies or gaps between the straight edge and the coil. The presence of such gaps indicates that the coil is not flat, necessitating further examination. Another technique utilized is the straight edge ruler method. Here, a ruler with a thin and flexible edge is applied to the surface of the coil. By applying gentle pressure, technicians can identify any areas where the ruler fails to fully make contact with the coil, indicating irregularities in its flatness. Advanced methods, including laser or optical techniques, are also employed to assess the flatness of aluminum coils. These methods employ laser beams or optical sensors to measure the surface profile of the coil. The collected data is then analyzed to determine if there are any deviations from the desired flatness. These sophisticated techniques provide precise and accurate results, enabling a more comprehensive evaluation of the coil's flatness. In conclusion, the testing of aluminum coils for flatness is of utmost importance in ensuring that they meet the required standards for a variety of applications. By utilizing a combination of visual inspection, straight edge techniques, and advanced laser or optical methods, manufacturers can guarantee that the coils are flat and devoid of any irregularities that could impact their performance.

- Q: Why the aluminum sheet crack after?

- It is either because of wrong filling material for welding or bad welding quality. It doesn’t crack after welding, but cracks when the increasing tension in circling process exceeds the internal stress of the weld.

- Q: What are the different joining methods for aluminum coils?

- There are several different joining methods for aluminum coils, depending on the specific application and desired strength of the bond. Some of the common joining methods for aluminum coils include: 1. Welding: Aluminum can be welded using different techniques such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or laser welding. Welding provides a strong and durable bond between the coils, ensuring structural integrity. 2. Brazing: Brazing involves melting a filler material, usually a copper-based alloy, to join two aluminum coils. This method is suitable for joining thin aluminum coils and provides a strong and leak-proof bond. 3. Adhesive bonding: Adhesive bonding is a non-destructive joining method that involves using a high-strength adhesive to bond the aluminum coils together. This method is often used when aesthetics and surface finish are crucial, as it does not require any visible welding or brazing marks. 4. Mechanical joining: Mechanical joining methods include techniques like riveting, clinching, and using fasteners like screws or bolts. These methods provide a reliable and easily reversible bond, making them suitable for applications where disassembly may be required. 5. Roll bonding: Roll bonding is a process where two or more aluminum coils are passed through a rolling mill under high pressure, resulting in the creation of a single composite coil. This method is commonly used for joining dissimilar metals or creating laminated structures with different alloy combinations. Each joining method has its advantages and limitations, and the choice of method depends on factors such as the desired strength, cost, production volume, and specific application requirements. It is important to consider these factors carefully to ensure the most suitable joining method is selected for aluminum coil applications.

- Q: What are the different packaging options available for aluminum coils?

- Customers have several packaging options to choose from for aluminum coils, depending on their specific needs and requirements. Some commonly used packaging options include: 1. Wooden crates: Sturdy wooden crates offer maximum protection for aluminum coils during transportation and storage. These crates are made of high-quality wood and designed to withstand rough handling, preventing coil damage. 2. Cardboard boxes: Smaller aluminum coils can be packaged in lightweight and cost-effective cardboard boxes. These boxes provide adequate protection against minor impacts and environmental factors. 3. Steel or aluminum skids: Aluminum coils can be placed on steel or aluminum skids for packaging. Skids provide a stable base and allow for easy handling using forklifts or pallet jacks. They are commonly used for larger coils or when transporting multiple coils together. 4. Stretch wrap: Stretch wrap is a popular choice for packaging aluminum coils. It offers excellent protection against dust, moisture, and scratches. The coils are tightly wrapped in plastic film, ensuring secure transportation. 5. Custom packaging: In certain cases, customers may require customized packaging solutions to meet specific requirements. This can include using protective covers, foam padding, or additional reinforcements to ensure safe handling and delivery of the aluminum coils. It is important to consider factors such as coil size, weight, transportation method, and intended use when choosing a packaging option. Working with a reputable packaging provider can help determine the most suitable packaging option for aluminum coils.

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a non-toxic and non-reactive metal that is safe for storing food. It is lightweight, durable, and has excellent temperature retention properties, making it a popular choice for food storage containers.

- Q: I heared the aluminum weakens or melts.

- Mercury readily combines with aluminium to form a mercury-aluminum amalgam when the two pure metals come into contact. However, when the amalgam is exposed to air, the aluminium oxidizes, leaving behind mercury. The oxide flakes away, exposing more mercury amalgam, which repeats the process. This process continues until the supply of amalgam is exhausted, and since it releases mercury, a small amount of mercury can “eat through” a large amount of aluminium over time, by progressively forming amalgam and relinquishing the aluminium as oxide. Aluminium in air is normally protected by a thin layer of its own oxide, which is not porous to mercury. Mercury coming into contact with this oxide does no harm. However, if any elemental aluminium is exposed (even by a recent scratch), the mercury may combine with it, starting the process described above, and potentially damaging a large part of the aluminium before it finally ends.

- Q: Can aluminum coils be used in signage applications?

- Yes, aluminum coils can be used in signage applications. Aluminum is a popular material for signage due to its durability, corrosion resistance, and lightweight nature. It can be easily formed into various shapes and sizes, making it suitable for different types of signage such as outdoor signs, billboards, trade show displays, and more. Additionally, aluminum coils offer excellent weather resistance, ensuring that the signage remains intact and vibrant even in harsh environmental conditions. The versatility and longevity of aluminum make it a preferred choice for signage applications in various industries.

Send your message to us

Sheet Aluminum Coil 1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords