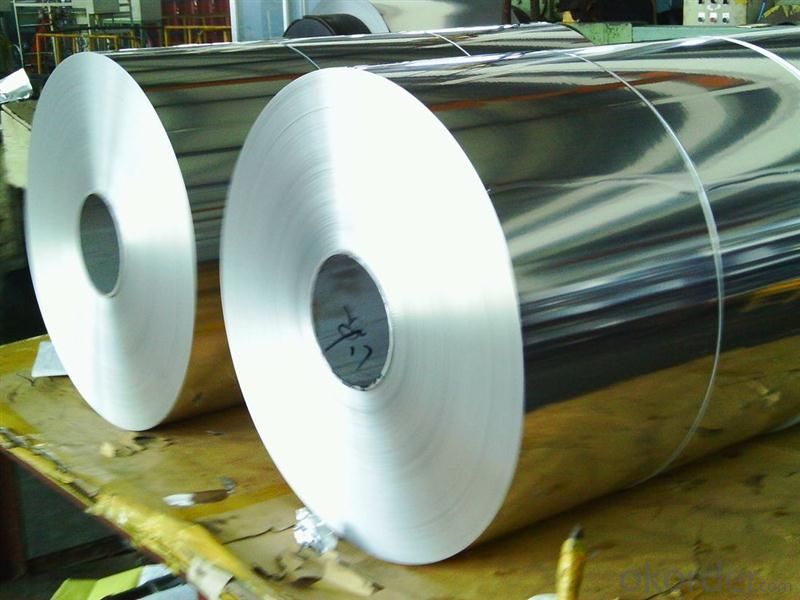

Custom Painted Aluminum Coil - 1100 Temper Ho 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 Temper Ho 0.5mm 0.8m 1mm Thickness Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: How do aluminum coils compare to other types of coils (e.g., copper)?

- The usage of aluminum coils and copper coils is prevalent in multiple industries. While each type has its own pros and cons, it is crucial to understand their relative comparisons. An important distinction between aluminum and copper coils is their conductivity. Copper is renowned for its exceptional electrical and thermal conductivity, making it the preferred choice for applications that necessitate efficient heat transfer. Conversely, aluminum possesses lower conductivity than copper, yet it still conducts electricity and heat effectively. Another factor to consider is cost. Copper is more expensive than aluminum due to its higher demand and limited availability. Consequently, aluminum coils are often chosen as a cost-effective alternative, particularly in applications where the high conductivity of copper is not necessary. In terms of weight, aluminum coils are significantly lighter than copper coils. This attribute facilitates easier handling and installation, leading to reduced transportation and labor costs. The lightweight nature of aluminum coils also renders them suitable for weight-sensitive applications, such as automotive and aerospace industries. In terms of corrosion resistance, copper coils outperform aluminum coils. Copper exhibits high resistance to corrosion, ensuring a longer lifespan and reduced maintenance requirements. Conversely, aluminum is more prone to corrosion, especially in environments with high humidity or exposure to specific chemicals. However, through proper coatings and treatments, aluminum coils can be effectively protected against corrosion. Durability is another crucial aspect to consider. Copper coils are known for their durability and ability to withstand extreme conditions, making them suitable for applications requiring longevity. While aluminum coils may not be as durable as copper, they can still offer satisfactory performance in many applications, particularly when designed and maintained appropriately. In conclusion, aluminum coils and copper coils possess distinct characteristics and advantages. Copper coils offer superior conductivity, corrosion resistance, and durability, albeit at a higher cost. On the other hand, aluminum coils are lighter, more cost-effective, and suitable for various applications. Ultimately, the choice between the two types of coils depends on specific requirements, budget constraints, and environmental factors of the given application.

- Q: What is the electrical conductivity of aluminum coils?

- The electrical conductivity of aluminum coils is very high, making aluminum an excellent choice for conducting electricity efficiently.

- Q: How are aluminum coils used in the production of signage and displays?

- Due to their versatility, durability, and cost-effectiveness, aluminum coils find extensive use in the manufacturing of signage and displays. These coils are typically composed of high-quality aluminum alloy, which provides excellent strength and resistance against corrosion. To achieve the desired thickness and shape, the production process starts by unwinding the aluminum coils and passing them through a series of rollers. This process, known as coil coating or pre-painting, allows for the application of various finishes and coatings onto the aluminum's surface. The type of coating used, such as polyester, polyurethane, fluorocarbon, or acrylic, depends on the specific requirements of the signage or display. After the coating process, the aluminum coils can be further processed into different forms, including flat sheets, strips, or custom shapes based on the design specifications. Aluminum's versatility enables easy fabrication and customization, which makes it a popular choice among signage and display manufacturers. Aluminum coils are widely employed in various signage applications, such as billboards, outdoor advertising panels, trade show displays, store signage, and architectural signage. The lightweight nature of aluminum simplifies transportation and installation, reducing production and installation costs. Furthermore, the durability of aluminum ensures that signage and displays made from aluminum coils can withstand harsh weather conditions, UV radiation, and other environmental factors, making them suitable for both indoor and outdoor applications. Aluminum's resistance to corrosion also contributes to the long-lasting quality of the signage, allowing it to maintain its appearance and functionality over time. Apart from its physical properties, the aesthetic appeal of aluminum is another reason for its extensive use in signage and displays. The smooth and reflective surface of the metal provides an attractive finish that enhances the visual impact of the signage, effectively capturing attention and conveying messages. In conclusion, aluminum coils are essential in the production of signage and displays due to their versatility, durability, cost-effectiveness, and aesthetic appeal. The ease of customization, combined with the resistance to corrosion and harsh environmental conditions, makes aluminum an ideal material for creating visually striking and long-lasting signage and display solutions.

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils are widely acknowledged for being remarkably high. Aluminum, as a material, possesses a remarkable strength-to-weight ratio, which renders it suitable for diverse applications that necessitate both strength and lightweight characteristics. The specific tensile strength of aluminum coils can vary based on the alloy and temper employed. In general, aluminum coils exhibit a tensile strength ranging from 110-310 MPa (megapascals), or approximately 16,000-45,000 psi (pounds per square inch). These figures denote the maximum tensile stress that the aluminum coil can endure before it fractures or permanently distorts. It should be emphasized that the tensile strength can be further improved through heat treatment procedures like cold rolling or annealing. On the whole, aluminum coils are renowned for their impressive tensile strength properties, which contribute to their extensive utilization in industries such as aerospace, automotive, construction, and manufacturing.

- Q: Is it possible to use an aluminum coil for cooking rice?

- <p>While it is technically possible to use an aluminum coil to cook rice, it is not recommended due to potential health risks. Aluminum can leach into food, especially when heated, and long-term exposure to aluminum may have adverse effects on health. Instead, use materials like stainless steel, cast iron, or non-stick cookware specifically designed for cooking rice to ensure safety and better results.</p>

- Q: Are aluminum coils suitable for marine applications?

- Indeed, aluminum coils prove to be fitting for marine applications. As a material resistant to corrosion, aluminum becomes an ideal option for deployment in marine settings that often encounter saltwater and other forms of corrosive elements. Lightweight, long-lasting, and boasting a high strength-to-weight ratio, aluminum coils hold significance in marine applications where weight reduction is sought after. Moreover, aluminum coils exhibit resilience in the face of extreme temperatures and possess commendable thermal conductivity, rendering them suitable for diverse marine heating and cooling systems. In summary, aluminum coils enjoy popularity in marine applications owing to their corrosion resistance, durability, and lightweight attributes.

- Q: Are aluminum coils fire-resistant?

- Aluminum coils possess fire-resistant qualities due to their high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and their inability to burn, rendering them non-combustible. This specific characteristic allows for the utilization of aluminum coils in various applications, particularly in sectors where fire resistance is of utmost importance, such as building construction, electrical wiring, and HVAC systems. Moreover, the remarkable heat conductivity of aluminum facilitates rapid heat dissipation, thereby minimizing the risk of fire incidents. Nevertheless, it is crucial to acknowledge that although aluminum coils themselves exhibit fire-resistant properties, they may be incorporated into systems alongside other components that might not share the same level of fire resistance. Consequently, it is essential to consider the entirety of the system and adhere to proper fire safety regulations and guidelines to ensure comprehensive fire safety precautions.

- Q: Can aluminum coils be used for heat sinks?

- Indeed, the utilization of aluminum coils as heat sinks is possible. Aluminum stands out as a favored option for heat sinks, thanks to its remarkable thermal conductivity attributes. These heat sinks are specifically engineered to disperse the heat generated by electronic parts, such as processors or power transistors, in order to avert overheating and guarantee optimum performance. By utilizing aluminum coils, heat can be effectively redirected away from the heat source and spread across a broader surface, resulting in efficient heat dissipation. Furthermore, aluminum possesses the advantages of being lightweight, resistant to corrosion, and cost-effective, rendering it an ideal material for heat sink applications.

- Q: What are the different surface finishes for pre-painted aluminum coils?

- The different surface finishes for pre-painted aluminum coils include smooth, textured, embossed, brushed, and metallic finishes.

- Q: I have a edelbrock aluminum intake that was sitting around for a year and it has some fading with a little corrosion. What's a good cleaner or chemical I can use to clean it up?

- I use Mother aluminum polish. It'll take a lot of patience and elbow grease but it works.

Send your message to us

Custom Painted Aluminum Coil - 1100 Temper Ho 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords