Self Adhesive Fiberglass Mesh Fabric with High Silica Texturized Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

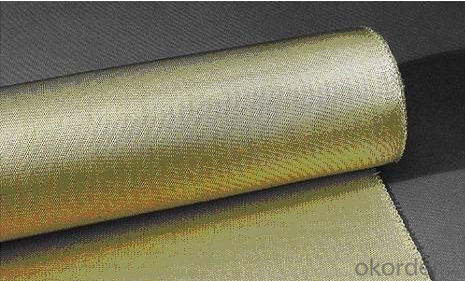

Our Silica Fibre fire Sleeve is an extreme high temperature, heat and flame resistant silica tape, and is an excellent alternative to asbestos and ceramic based textiles. The Silica Fibre Sleeve are primarily used as the thermal protection of circular items, the sleeves can be applied in aerospace (gas turbin and rocket engines), metallurgical, nuclear power, electricity generation, petrochemical industries, etc. for example, tube seals, high temperature gaskets, heaters,reformers,turbine exhaust,boilers, thermocouple wire,etc.

Applifications:

High silica texturized tapes can be used for a long period of time without changing its properties at the temperature of 1000℃,as it contains more than 96% silica.The performance of thermal insulation is excellent because of its texturized structure..

Application:Industrial wires,cables and pipes as thermal insulation material,heat gasket and seal material.

Specification:

| Product Code | SiO2 % | Working Temperature ℃ | Width mm | Thickness | Packing M/Roll |

| TSIP-32-0.8 | ≥94% | 1000 | 32-100 | 0.8 | 10,15,20 |

| TSIP-32-1.0 | ≥94% | 1000 | 32-100 | 1 | 10,15,20 |

| TSIP-32-1.5 | ≥94% | 1000 | 32-100 | 1.5 | 10,15 |

| TSIP-32-2.0 | ≥94% | 1000 | 32-100 | 2 | 10,15 |

| TSIP-32-2.5 | ≥94% | 1000 | 32-100 | 2.5 | 10,15 |

Package and delivery time

Package:Each roll in a polybag,then several rolls in one standard export carton box.

Delivery time:Within 7-15days

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Is fiberglass fabric resistant to chemical degradation?

- The excellent resistance to chemical degradation exhibited by fiberglass fabric is well-known. Its composition of glass fibers, which are impervious to most chemicals, allows it to withstand the effects of various corrosive substances with high resistance. Fiberglass fabric can endure exposure to acids, alkalis, solvents, oils, and other chemicals commonly present in industrial environments without experiencing significant degradation. This quality makes it the preferred choice for applications where chemical resistance is of utmost importance, such as in the manufacturing of chemical storage tanks, pipes, and linings. Furthermore, the durability and longevity of fiberglass fabric are also enhanced by its resistance to chemical degradation, making it a dependable material for a wide range of industrial and commercial uses.

- Q: Can fiberglass fabric be used for geotextiles?

- Certainly! Geotextiles can indeed utilize fiberglass fabric. This material is incredibly versatile and possesses exceptional strength, durability, and resistance against harsh environmental conditions. It finds widespread use in numerous applications, including geotextiles. Geotextiles, in turn, refer to synthetic materials employed in civil engineering and construction projects to reinforce soil, segregate different soil layers, and combat erosion. The fiberglass fabric employed for geotextiles is specially engineered to possess high tensile strength, enabling it to withstand soil-induced forces. It effectively reinforces feeble soils, stabilizes slopes, and prevents soil erosion. Moreover, fiberglass fabric geotextiles exhibit resistance to chemicals, UV radiation, and biological degradation, ensuring prolonged performance under challenging environmental circumstances. There are several advantages to employing fiberglass fabric geotextiles. Firstly, they exhibit excellent filtration properties, permitting water passage while retaining soil particles. This aids in maintaining soil structure stability and drainage. Secondly, fiberglass fabric geotextiles are lightweight and easy to install, reducing labor and time expenses. Lastly, they boast a lengthy service life and require minimal maintenance, thereby proving a cost-effective solution for geotechnical applications. On the whole, fiberglass fabric can be reliably and durably employed for geotextiles, providing robust reinforcement for diverse civil engineering and construction projects.

- Q: Can fiberglass fabric be used for air ducts?

- Indeed, air ducts can make effective use of fiberglass fabric. Given its exceptional thermal and acoustic insulation attributes, fiberglass fabric has become a favored option for insulating air ducts. Its lightweight composition, flexibility, and resistance to fire, moisture, and mold growth make it an ideal material for incorporation into air duct systems. Moreover, the installation of fiberglass fabric is simple, and it aids in enhancing energy efficiency by minimizing heat loss or gain through the ductwork. Nevertheless, it is crucial to verify that the fiberglass fabric utilized in air ducts adheres to industry standards and regulations to guarantee optimal performance and safety.

- Q: How is fiberglass fabric used in the automotive industry?

- Due to its unique properties, fiberglass fabric finds extensive use in the automotive industry for a variety of purposes. One of the primary applications of fiberglass fabric in this sector involves the production of car parts such as body panels, hoods, and spoilers. The choice of fiberglass fabric for these purposes is driven by its lightweight, strong, and durable nature. This material boasts an impressive strength-to-weight ratio, enabling it to provide robustness to car parts without adding unnecessary weight. This aspect is crucial in enhancing fuel efficiency and overall vehicle performance. Furthermore, fiberglass fabric is also employed in the automotive industry for insulation purposes. It is commonly utilized to insulate engine components, including exhaust systems and heat shields, safeguarding surrounding parts against excessive heat. The remarkable temperature resistance of fiberglass fabric renders it an ideal option for these applications. Moreover, fiberglass fabric contributes significantly to the manufacturing of automotive interiors. It is frequently utilized in upholstery, door panels, headliners, and trunk liners. The fabric's exceptional flexibility allows it to conform effortlessly to various shapes and contours of the car interior. Additionally, it exhibits resistance to stains, chemicals, and fading, ensuring a long-lasting and visually appealing interior finish. Additionally, fiberglass fabric serves as a reinforcement material in the automotive industry. It is often incorporated as a layer in the production of composite materials used for manufacturing car parts. By combining fiberglass fabric with resins or other materials, manufacturers can create robust and rigid components capable of withstanding impacts, vibrations, and other external forces. Overall, fiberglass fabric plays a crucial role in the automotive industry, offering lightweight, durable, and heat-resistant solutions for diverse applications. Its versatility and exceptional properties make it an ideal material for manufacturing car parts, insulation, interiors, and reinforcement, thereby contributing to the efficiency, safety, and overall quality of vehicles.

- Q: What are the different fiberglass fabric coatings for oil resistance?

- Multiple options for fiberglass fabric coatings with oil resistance are available. Some commonly used coatings are as follows: 1. Neoprene: With high resistance to oil and excellent durability, neoprene coatings create a strong barrier against oil penetration. They are frequently employed in situations where oil resistance is crucial. 2. Nitrile: Nitrile coatings are also highly resistant to oil and known for their resistance to chemicals and abrasion. They reliably protect against oil and are commonly used in industrial settings where oil exposure is frequent. 3. PVC: PVC coatings offer oil resistance and good durability. They provide a moderate level of oil resistance and are often chosen when a balance of oil resistance and flexibility is required. 4. Polyurethane: Offering good oil resistance, polyurethane coatings are flexible and highly resistant to abrasion. They establish a strong barrier against oil penetration and are frequently used in applications where both oil resistance and flexibility are essential. It is important to note that the effectiveness of these coatings may vary depending on the specific application and the type of oil or chemical being used. It is always advisable to consult with the manufacturer or supplier to determine the most suitable coating for your specific requirements.

- Q: Does fiberglass fabric provide UV protection?

- Yes, fiberglass fabric provides UV protection.

- Q: What are the different thicknesses of fiberglass fabric used in insulation?

- The different thicknesses of fiberglass fabric used in insulation can vary depending on the specific application and desired level of thermal resistance. Generally, fiberglass fabric for insulation purposes is available in a range of thicknesses, typically starting from 1 inch (25mm) and going up to 4 inches (100mm) or more. However, it's important to note that the specific thicknesses available may vary among manufacturers and regions. The chosen thickness is determined by factors such as the desired insulation R-value, the space available for insulation installation, and the specific requirements of the building or project. Thicker fiberglass fabric generally provides higher thermal resistance, which results in better insulation performance, effectively reducing heat transfer and energy loss. However, thicker insulation also requires more space for installation and may be costlier. Therefore, it's crucial to consider the specific needs and constraints of the project to determine the appropriate thickness of fiberglass fabric for insulation.

- Q: What is the material of the computer mainboard PCB?

- The six panel adds the auxiliary power layer and the signal layer. The six layer PCB board has stronger electromagnetic interference resistance, and the mainboard is more stable.

- Q: What are the different weaves available for fiberglass fabric?

- There are several different weaves available for fiberglass fabric, each with its own unique characteristics and uses. Some of the most common weaves include plain weave, twill weave, satin weave, and leno weave. Plain weave is the simplest and most common weave used for fiberglass fabric. It is characterized by an equal number of warp and weft yarns crossing over and under each other in a simple over-under pattern. This weave creates a strong and balanced fabric with good stability and durability. Twill weave is another popular option for fiberglass fabric. In this weave, the warp and weft yarns cross over and under each other in a diagonal pattern, creating a distinctive diagonal ribbing effect. Twill weave provides better drapability and flexibility compared to plain weave, making it suitable for applications that require greater conformability. Satin weave is a more complex weave that produces a smooth and shiny surface on the fabric. It is characterized by long floats of the warp or weft yarns, which means that fewer yarns are interlaced, resulting in a more flexible and lightweight fabric. Satin weave is often used in applications where a high-quality appearance and a soft feel are desired, such as in the production of clothing or decorative fabrics. Leno weave is a unique weave that involves twisting adjacent warp yarns around each other to create a stable and open mesh structure. This weave is commonly used for fiberglass fabrics that require high transparency and breathability, as well as for applications that involve filtration or reinforcement purposes. Overall, the choice of weave for fiberglass fabric depends on the specific requirements of the application. By considering factors such as strength, flexibility, appearance, and breathability, one can select the most suitable weave to achieve optimal performance in their desired application.

- Q: Can fiberglass fabric be used for car covers?

- Yes, fiberglass fabric can be used for car covers. Fiberglass fabric is known for its durability and resistance to tearing, making it a suitable material for protecting cars from various external elements such as dust, dirt, and UV rays. It is also lightweight, easy to handle, and can be easily customized to fit different car sizes and shapes. Additionally, fiberglass fabric has excellent heat insulation properties, which can help protect the car's interior from extreme temperatures. However, it is important to note that fiberglass fabric on its own may not be waterproof, so it is recommended to use a waterproof coating or layer underneath the fabric for added protection against rain and moisture.

Send your message to us

Self Adhesive Fiberglass Mesh Fabric with High Silica Texturized Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords