Welded and seamless 201 202 304 304L 316 316L stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Welded and seamless 201 202 304 304L 316 316L stainless steel pipe

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 59, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.24-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe) |

Chemical Composition | |||||||

Material | C | Si | Mn | P | S | Cr | Ni |

201 | ≤0.12 | ≤0.75 | 9.5-12.5 | ≤0.045 | ≤0.03 | 13-16 | 0.8-1.5 |

304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18-19 | 8-10 |

316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.035 | ≤0.03 | 10-14 | 16.0-18.5 |

430 | ≤0.12 | ≤0.75 | ≤2.0 | ≤0.04 | ≤0.03 | 16-18 | ≤0.6 |

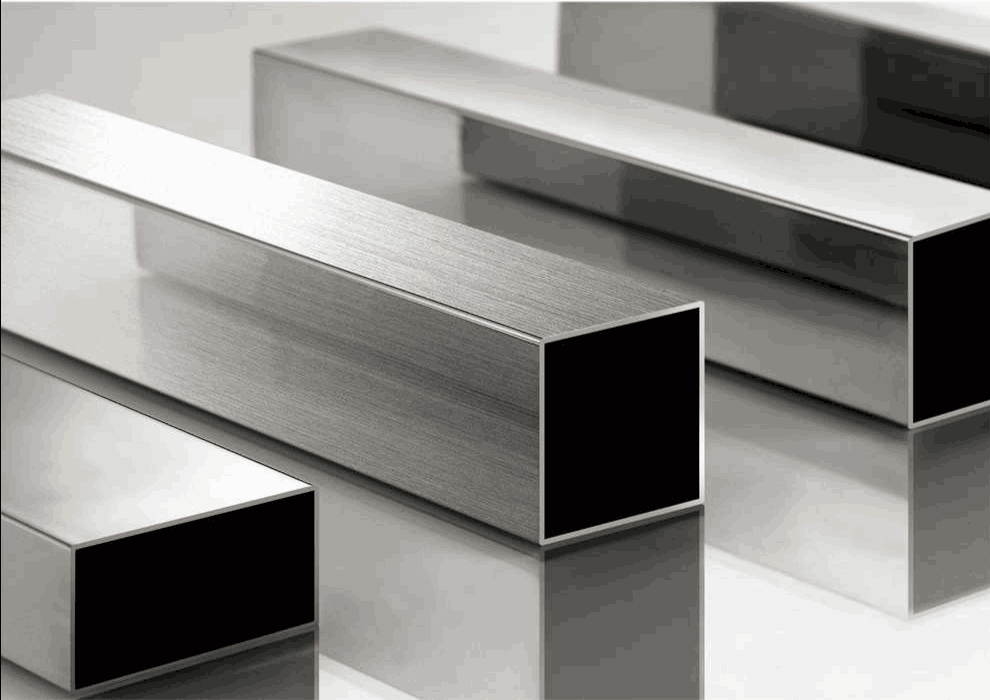

Square pipe and rectangle pipe

round pipe

PACK & DELIVERY

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

COMPANY INFORMATION

Company Information

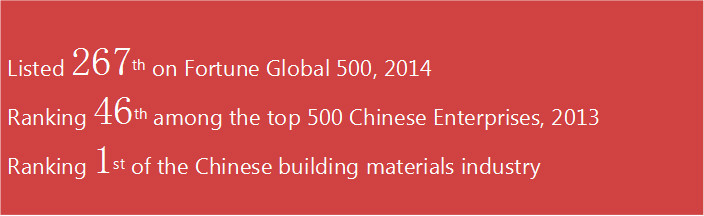

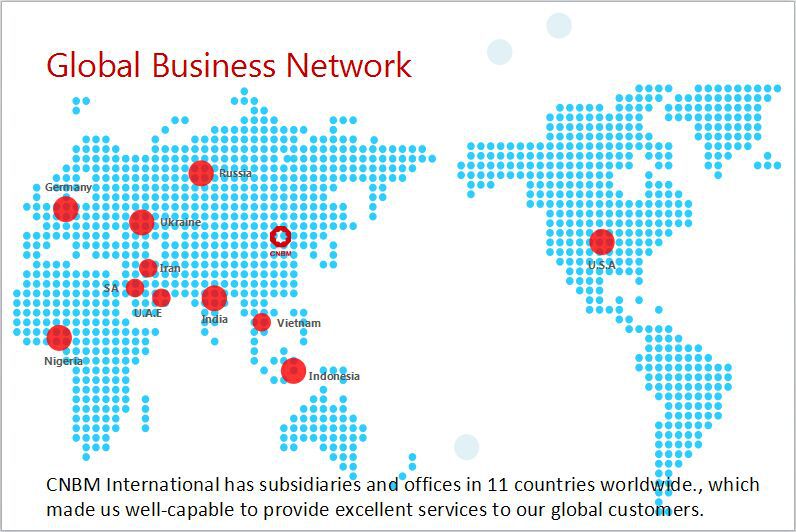

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

WORK SHOP

Client

Export Markets Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

- Q: Can stainless steel pipes be used in power plants?

- Yes, stainless steel pipes can be used in power plants. Stainless steel has excellent corrosion resistance, high-temperature strength, and durability, making it suitable for various applications in power plants, including transporting fluids and gases, supporting structural components, and handling high-pressure environments.

- Q: Can stainless steel pipes be used for both high and low-pressure applications?

- Yes, stainless steel pipes can be used for both high and low-pressure applications. Stainless steel pipes are known for their excellent strength, durability, and corrosion resistance, making them suitable for various pressure conditions. They are commonly used in industries such as oil and gas, chemical processing, and power generation, where both high and low-pressure applications are encountered.

- Q: Are stainless steel pipes suitable for geothermal applications?

- Yes, stainless steel pipes are suitable for geothermal applications. Geothermal systems involve the extraction of heat from the earth's natural geothermal energy, which often requires the transportation of hot fluids such as water or steam. Stainless steel pipes are an excellent choice for this purpose due to their high strength, corrosion resistance, and ability to withstand high temperatures. They are able to withstand the harsh conditions of geothermal environments, including the presence of acidic or corrosive fluids, and are less likely to degrade over time compared to other materials. Additionally, stainless steel pipes offer excellent thermal conductivity, ensuring efficient heat transfer in geothermal applications. Overall, stainless steel pipes are a reliable and durable option for geothermal systems.

- Q: What is the difference between 321 and 321H stainless steel pipes?

- The main difference between 321 and 321H stainless steel pipes lies in their carbon content. 321H contains a higher amount of carbon, which improves its high-temperature strength and resistance to sensitization during welding. This makes 321H more suitable for applications requiring elevated temperatures, while 321 is typically used in lower temperature environments.

- Q: What is the difference between 347 and 347H stainless steel pipes?

- The main difference between 347 and 347H stainless steel pipes lies in their carbon content. 347 stainless steel pipes have a maximum carbon content of 0.08%, while 347H stainless steel pipes have a higher carbon content range of 0.04-0.10%. This higher carbon content in 347H pipes provides improved high-temperature strength and greater resistance to sensitization, which is the formation of chromium carbides at grain boundaries that can lead to intergranular corrosion. Due to its higher carbon content, 347H stainless steel pipes are typically recommended for applications involving elevated temperatures and thermal cycling. They offer enhanced creep resistance and can withstand higher stress levels than 347 stainless steel pipes. 347H pipes are commonly used in industries such as chemical processing, petrochemical, and power generation, where they are exposed to high temperatures and corrosive environments. In summary, the difference between 347 and 347H stainless steel pipes lies in their carbon content, with 347H pipes offering improved high-temperature strength and resistance to sensitization. The choice between the two depends on the specific application requirements and operating conditions.

- Q: Are stainless steel pipes resistant to scaling and oxidation?

- Yes, stainless steel pipes are highly resistant to scaling and oxidation due to the presence of chromium in their composition, which forms a protective oxide layer on the surface, preventing corrosion and scaling.

- Q: Can stainless steel pipes be insulated with foam?

- Yes, stainless steel pipes can be insulated with foam. Foam insulation is commonly used to improve energy efficiency and reduce heat or cold loss in various types of pipes, including stainless steel ones. The foam insulation helps to prevent condensation and provides thermal protection, making it an effective solution for insulating stainless steel pipes.

- Q: Can stainless steel pipes be used for petrochemical plants?

- Yes, stainless steel pipes can be used for petrochemical plants. Stainless steel is highly resistant to corrosion, making it an ideal choice for petrochemical plants where corrosive substances are handled. These pipes are capable of withstanding high temperatures and pressures, making them suitable for the harsh operating conditions of petrochemical plants. Additionally, stainless steel pipes have excellent mechanical properties, which ensure their durability and reliability in such industrial environments. Moreover, stainless steel pipes are easy to clean and maintain, reducing the risk of contamination and facilitating efficient operations in petrochemical plants.

- Q: What is the maximum temperature that stainless steel pipes can handle?

- The maximum temperature that stainless steel pipes can handle depends on the specific grade of stainless steel being used. Generally, stainless steel pipes are known for their high temperature resistance, which makes them suitable for a variety of applications in industries such as petrochemical, oil and gas, and power generation. The most common grades of stainless steel used in pipes, such as 304 and 316, have a maximum operating temperature of around 870°C (1600°F). These grades have excellent corrosion resistance and can withstand high temperatures, making them suitable for a wide range of industrial processes. However, there are some specialized stainless steel grades, such as 310 and 321, which can handle even higher temperatures. These grades have higher chromium and nickel content, providing enhanced resistance to oxidation and scaling at temperatures up to 1150°C (2100°F). It is important to note that the maximum temperature that stainless steel pipes can handle also depends on other factors such as the duration of exposure, the presence of corrosive environments, and the specific application requirements. Therefore, it is always recommended to consult with a materials engineer or a manufacturer to determine the appropriate grade and maximum temperature limits for a specific stainless steel pipe application.

- Q: What is stainless steel pipe made of?

- Stainless steel pipes are made primarily from a corrosion-resistant alloy composed of iron, chromium, and varying amounts of other elements such as nickel, manganese, and molybdenum.

Send your message to us

Welded and seamless 201 202 304 304L 316 316L stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords