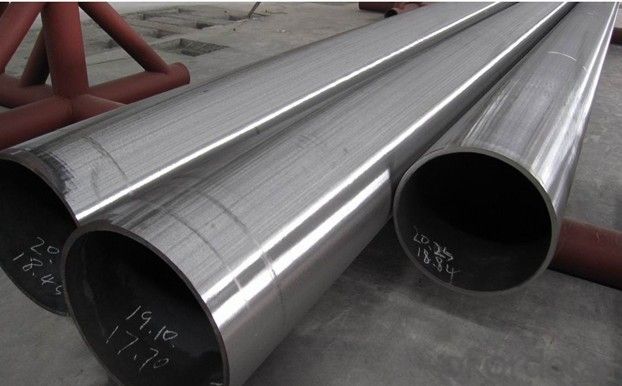

Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product name

ASTM A335 alloy steel pipe

2/ Standard

ASTM SA213, SA335, A369, A209, A250, G3462, G3467, DIN17175, BS3059-2

3/ Material

A213: T2, T5, T9, T11, T12, T22, T91, T92

A335: P1, P2, P5, P9, P11, P12, P21, P22, P91, P92

DIN17175: 15Mo3, 13CrMo44, 10CrMo910, 12CrMo195

BS3059: 360, 440, 460, 620

JIS G3458: STPA12, STPA20, STPA22, STPA23, STPA24, STPA25, STPA26

JIS G3462: STPA12, STBA13, STBA20, STBA22, STBA23, STBA24, STBA25, STBA26

4/ Outside diameter: 141.3mm~720mm

5/ Wall Thickness: 25mm~100mm

6/ Length: 6m-12m, also can be manufactured by customers' requirements

7/ Type: Seamless

8/ Type of ends: Plain ends or bevel ends

9/ Coating for protection: Can be required according to customers' requirement

10/ Application: Widely used in oil, chemical industry, electricity, boiler industry of high-temperature resistance, low temperature resistance, corrosion resistance in pilie lines, etc.

ASTM A335 Seamless Alloy-Steel Pipe

Standard: BS 1139, BS 3059-2, JIS G3454-2007

Grade: 10#-45#, 15NiCuMoNb5, 10Cr9Mo1VNb

Detailed introduction to ASTM A335 seamless alloy steel pipe:

ASTM A335 seamless alloy steel pipe

Packaging Detail: | Bundle or Container or as per customers requirement. |

Delivery Detail: | within 25 days after we receive an irrevocable L/Cor 30% deposit |

ASTM A335 Seamless Alloy-Steel Pipe

Standard: BS 1139, BS 3059-2, JIS G3454-2007

Grade: 10#-45#, 15NiCuMoNb5, 10Cr9Mo1VNb

Detailed introduction to ASTM A335 seamless alloy steel pipe:

ASTM A335 seamless alloy steel pipe

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

- Q: What is the thermal conductivity of steel pipes?

- The thermal conductivity of steel pipes can vary depending on the specific type of steel and its composition, but generally, steel has a relatively high thermal conductivity compared to other materials. It is typically around 50-60 W/m·K.

- Q: How are steel pipes protected against underground corrosion?

- Steel pipes are typically protected against underground corrosion through various methods such as coating the pipes with corrosion-resistant materials like epoxy or polyethylene, cathodic protection using sacrificial anodes or impressed current systems, and regular inspection and maintenance to detect and address any signs of corrosion.

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel pipes are known for their strength and durability, making them suitable for various applications. They are capable of withstanding high pressures without deformation or leakage, while also being reliable for low-pressure systems.

- Q: Can steel pipes be used for gas lines?

- Yes, steel pipes can be used for gas lines. Steel pipes are commonly used for gas lines due to their high strength and durability, making them suitable for transporting natural gas or propane safely and efficiently.

- Q: What are the different methods of welding steel pipes?

- There are several different methods of welding steel pipes, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW). Each method has its own advantages and is used depending on factors such as the thickness of the pipes, the type of steel being welded, and the desired outcome.

- Q: What are the typical lengths of steel pipes?

- The typical lengths of steel pipes can vary depending on their purpose and application. However, common lengths range from 20 feet (6 meters) to 40 feet (12 meters) in commercial and industrial settings.

- Q: Can steel pipes be used for underground water supply networks?

- Yes, steel pipes can be used for underground water supply networks. Steel pipes are commonly used for underground water supply networks due to their durability, strength, and resistance to corrosion. They can withstand high pressure and are able to handle the weight of the soil and other external forces. Additionally, steel pipes are available in various sizes and can be easily welded, making them suitable for different water supply system requirements. However, it is important to take into consideration factors such as the quality of the soil, the presence of chemicals or corrosive substances, and the need for regular maintenance to ensure the longevity and efficiency of the steel pipes in underground water supply networks.

- Q: What's the use of steel pipe?

- No other type of steel can replace the steel tube entirely, but the steel tube can take the place of some sections and bars. Steel pipe is very important to the development of national economy and the improvement of human life quality, much better than other steel products. From the people's daily utensils, furniture, water supply and drainage, gas supply, ventilation and heating facilities to all kinds of agricultural machinery equipment manufacturing, underground resources development, national defense and space use guns, bullets, missiles, rockets and so cannot do without steel.

- Q: What are the common challenges faced during steel pipe installation?

- Some common challenges faced during steel pipe installation include obtaining accurate measurements and ensuring proper alignment, dealing with obstructions or difficult terrain, managing the weight and size of the pipes, ensuring proper sealing and connections, and adhering to safety regulations and protocols.

- Q: Are steel pipes suitable for food processing facilities?

- Yes, steel pipes are suitable for food processing facilities. Steel is a durable and hygienic material that is resistant to corrosion, making it ideal for transporting food products and maintaining their quality and safety. Additionally, steel pipes are easy to clean and disinfect, further ensuring sanitation standards in food processing facilities.

Send your message to us

Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords