P5,Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging Detail: | Bundle or Container or as per customers requirement. |

Delivery Detail: | within 25 days after we receive an irrevocable L/Cor 30% deposit |

Specifications

1) ASTM A335 P11 Steel Pipe&Tube

2) Outer Diameter: 10-914mm

3) Wall thickness: 1-100mm

4) Length:3-16m

Cangzhou Qiancheng Steel-Pipe Group Co.(QCCO)

Our products and sizes scope is as following,

SEAMLESS PIPE OD: 3/8"-36"(17.1mm-914.4mm), WT: 2-100mm,

COLD DRAW TUBES OD: 3/8"-3-1/2" (17.1mm-88.9mm),

HOT ROLLES PIPES OD: 4"-8" (114mm-219.1mm),

HOT EXPANSION OD: 10"-36" (273mm-914mm),

LSAW SIZES SCOPE OD: 16” - 56”( 406.4mm-1422mm),WT 8mm-55mm,

OCTG:Seamless and ERW Casing and Tubing OD: 2-3/8" - 20", WT: 3mm-20mm,

Seamless Steel Tubes for Gas Cylinder GB18248

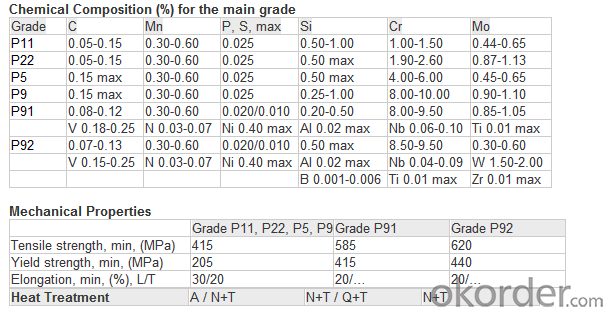

Detailed introduction to ASTM A335 seamless alloy steel pipe:

ASTM A335 seamless alloy steel pipe

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

- Q: What brand of stainless steel pipe cutting machine is good?

- Stainless steel cutting pipe should take into account the cutting speed, accuracy, cross section flatness, surface scratches, cutting tool loss and so on

- Q: Can stainless steel pipes be used for gas applications?

- Indeed, gas applications can utilize stainless steel pipes. Thanks to their remarkable resistance to corrosion and ability to endure elevated temperatures, stainless steel proves an ideal material for gas transportation. Moreover, these pipes boast exceptional strength and durability, instilling confidence in the safety and dependability of the gas system. Consequently, they find widespread use in industrial, commercial, and residential settings where gas transport is necessary. Nonetheless, it remains crucial to verify that the stainless steel pipes employed meet the precise criteria and standards for gas applications, guaranteeing optimal installation and performance.

- Q: What are the different types of stainless steel pipe unions?

- There are various types of stainless steel pipe unions, including threaded unions, socket weld unions, and butt weld unions. Threaded unions have female threads on both ends, allowing them to be easily screwed onto male threaded pipes. Socket weld unions have one socket end and one threaded end, allowing for easy welding onto pipes. Butt weld unions have two plain ends that are welded directly to pipes using the butt welding technique.

- Q: What is the maximum operating pressure for stainless steel pipes?

- The maximum operating pressure of stainless steel pipes is determined by several factors, including the grade of stainless steel, pipe diameter, and fluid temperature. In general, stainless steel pipes have higher pressure handling capabilities compared to other materials due to their inherent strength and resistance to corrosion. For instance, stainless steel pipes made from grade 304 or 316, which are commonly used across various industries, can withstand maximum operating pressures ranging from 1000 to 3000 psi or even higher, depending on the specific application and pipe size. However, it is essential to refer to the manufacturer's specifications and guidelines to ascertain the exact maximum operating pressure for a particular stainless steel pipe. It is important to consider that the maximum operating pressure can also be influenced by factors such as pipe wall thickness, pipe fittings, and joint connections. Hence, proper design, installation, and maintenance are crucial to ensure the safe and efficient operation of stainless steel pipes at their maximum operating pressure. Seeking guidance from a professional engineer or a specialist in stainless steel piping systems can provide accurate and specific information for a given application.

- Q: Can stainless steel pipes be used for pharmaceutical applications?

- Yes, stainless steel pipes can be used for pharmaceutical applications. Stainless steel is a preferred material in the pharmaceutical industry due to its high corrosion resistance, durability, and easy maintenance. It is used for transporting and storing various pharmaceutical products, as it ensures hygiene, does not react with drugs or chemicals, and can withstand high temperatures and pressure. Additionally, stainless steel pipes can be easily cleaned and sterilized, making them suitable for pharmaceutical applications.

- Q: What is the difference between 17-4 and 316 stainless steel pipes?

- The main difference between 17-4 and 316 stainless steel pipes lies in their composition and properties. 17-4 stainless steel is a precipitation-hardening stainless steel that contains 17% chromium, 4% nickel, and 4% copper. It is known for its high strength, excellent corrosion resistance, and good toughness. This type of stainless steel is commonly used in applications that require high strength and resistance to wear and corrosion, such as aerospace components, industrial equipment, and oil and gas applications. On the other hand, 316 stainless steel is an austenitic stainless steel that contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. It is highly corrosion-resistant and has good heat resistance. 316 stainless steel pipes are widely used in industries that require resistance to chemicals, saltwater, and various corrosive environments, such as marine applications, chemical processing, and pharmaceutical equipment. In summary, while both 17-4 and 316 stainless steel pipes offer corrosion resistance, 17-4 is known for its high strength and toughness, making it suitable for demanding applications, whereas 316 stainless steel is preferred for its exceptional corrosion resistance, particularly in harsh environments.

- Q: What is the difference between 304 and 304H stainless steel pipes?

- The carbon content is the main factor distinguishing 304 and 304H stainless steel pipes. Both materials consist of iron, chromium, and nickel, but 304H stainless steel has a higher carbon content compared to 304 stainless steel. This increased carbon content in 304H enhances its strength and resistance to deformation at high temperatures, making it more suitable for applications involving elevated temperatures. The higher carbon content in 304H stainless steel pipes also improves their ability to resist sensitization during welding. Sensitization refers to the formation of chromium carbides at the grain boundaries, which can lead to intergranular corrosion and reduced mechanical properties. By incorporating a higher carbon content, 304H stainless steel pipes can effectively resist this sensitization phenomenon and maintain their structural integrity even at high temperatures. Both 304 and 304H stainless steel pipes exhibit excellent corrosion resistance, good weldability, and high strength. They find extensive use in various industries, including oil and gas, chemical, food processing, and pharmaceuticals. However, it is worth noting that 304H stainless steel pipes are typically recommended for applications requiring high-temperature strength, while 304 stainless steel pipes are more commonly used for general-purpose applications. In conclusion, the carbon content distinguishes 304 and 304H stainless steel pipes. 304H stainless steel pipes have a higher carbon content, which enhances their high-temperature strength and resistance to sensitization during welding. These differences should be taken into account when selecting the appropriate stainless steel pipe for a specific application.

- Q: What are the dimensions and sizes of stainless steel pipes?

- The dimensions and sizes of stainless steel pipes can vary greatly depending on the specific application and industry requirements. Stainless steel pipes are available in various sizes, ranging from small diameter tubes of a few millimeters to larger pipes with diameters exceeding several feet. The dimensions of stainless steel pipes are typically specified by their outer diameter (OD), wall thickness, and length. The wall thickness can vary based on the intended use and pressure requirements of the pipe. Additionally, stainless steel pipes can be found in different shapes, such as round, square, or rectangular, to suit various installation needs.

- Q: What is the working temperature range for stainless steel pipes?

- The working temperature range for stainless steel pipes typically ranges from -150°C (-238°F) to 816°C (1500°F).

- Q: Can stainless steel pipes be coated?

- Stainless steel pipes have the capability to undergo coating procedures. Coating these pipes serves multiple purposes, such as bolstering their durability, preventing corrosion, providing insulation, and enhancing their aesthetics. There exist diverse options for coating stainless steel pipes, including epoxy coatings, polyurethane coatings, and fusion-bonded epoxy coatings. These coatings are applied to the surface of the stainless steel pipes using various techniques, such as spraying, dipping, or electrophoretic deposition. The selection of the appropriate coating relies on the specific requirements of the application and the environment in which the pipes will be utilized. By coating stainless steel pipes, their lifespan can be significantly extended and their performance can be improved, making them suitable for a wide range of industries including oil and gas, chemical, water treatment, and construction.

Send your message to us

P5,Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords