Carbon Steel Pipes For High Temperature ServiceE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

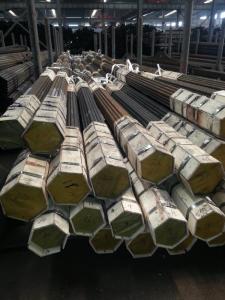

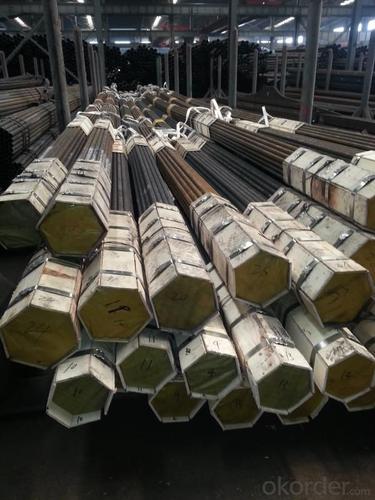

Specification of Carbon Steel Pipes For High Temperature ServiceE

Standard: JIS G3456

Grade: STS 38, STS 42, STS 49.

OD: 10.5-660.4 mm.

Thickness: 1.7-64.2mm

Length:39.34'/12M.max...

Standard: JIS G3456

Grade: STS 38, STS 42, STS 49.

OD: 10.5-660.4 mm.

Thickness: 1.7-64.2mm

Length:39.34'/12M.max...

Standard of Carbon Steel Pipes For High Temperature Service E

JIS G3444,ASTM A53/ASTM A36

BS1387/BS1139/EN39/EN10219/EN10217/EN10297/EN10296/EN10025

DIN EN10216,DIN EN10208,DIN EN10217, DIN28180,DIN17175, DIN EN10305, DINEN 10025

Q195/215/235/345,SS330/SS400/SS500,S235JR/S235J0/S235J2,STK290,STK400,STK490,STK500,STK540 | |||

O.D | O.D tolerance | W.T | Thickness Tolerance |

48.3MM/11/2'' | ±0.5mm | 2.0-4.0MM | ±1% |

Length |

5.8-6.4M as per customers' requirements | ||

Certificate |

ISO9001-2008,EN10210,API,Raw material cert,Mill cert,Reap on site inspection report,SGS,BV | ||

Standard |

JIS G3444

ASTM A53/ASTM A36

BS1387/BS1139/EN39/EN10219/EN10217/EN10297/EN10296/EN10025

DIN EN10216,DIN EN10208,DIN EN10217, DIN28180,DIN17175, DIN EN10305, DINEN 10025 | ||

Material |

Q195/215/235/345,

SS330/400/500,

S235JR/S235J0/S235J2,

STK290,STK400,STK490,STK500,STK540 | ||

Inspection : |

With Hydraulic Testing, Eddy Current , Infrared Test | ||

Technique: |

Welded:Cold drawn,Hot rolled,heat extrusion | ||

Packing |

In bundles or according to customers' requirements | ||

Usage |

construction | ||

Main market: |

USA,Middle east,North and South America, Europe, South and southeast Asia,Australia,Africa, | ||

Origin place |

Hebei,China | ||

HS code: |

73063090 | ||

Productivity |

20000Ton/Month | ||

Processing |

galvanzied,Bared,painting,embossing,oiled,greeve,print etc | ||

Remarks |

1)Payment term : T/T,L/C,DP

2)Trade Terms : FOB / CFR /CIF

3)Minimum quantity of order:15 MT

4)Delivery period :15 to 30 Days . | ||

- Q: What is the difference between steel pipe and fiberglass pipe?

- Steel pipe and fiberglass pipe differ in terms of material composition, durability, flexibility, and cost. Steel pipe is made of steel, which provides strength and resilience, making it ideal for high-pressure applications and underground installations. Fiberglass pipe, on the other hand, is composed of reinforced plastic fibers, resulting in a lightweight and corrosion-resistant material suitable for above-ground and corrosive environments. While steel pipe offers higher tensile strength, fiberglass pipe excels in its flexibility, allowing for easier installation and reduced maintenance. Additionally, steel pipe is typically more expensive due to the cost of materials and manufacturing processes, while fiberglass pipe is more cost-effective in terms of initial installation and long-term maintenance.

- Q: Are steel pipes suitable for nuclear power plants?

- Yes, steel pipes are suitable for nuclear power plants. Steel is a commonly used material in the construction of nuclear power plants due to its excellent mechanical properties, high strength, and durability. Steel pipes are used in various applications within these plants, including the transportation of cooling water, hot gases, and steam. The steel used in nuclear power plants is carefully selected and tested to meet stringent safety regulations and quality standards. It is crucial for these pipes to have excellent resistance to corrosion and high-temperature environments, as they are exposed to harsh conditions such as high pressure, high temperatures, and radioactive materials. Furthermore, steel pipes have a long service life and require minimal maintenance, making them a cost-effective choice for nuclear power plants. They can withstand extreme conditions, ensuring the safe and reliable operation of the plant. Additionally, steel pipes can be easily fabricated, installed, and repaired, which is essential for the efficient functioning of a nuclear power plant. Overall, steel pipes are highly suitable for nuclear power plants due to their strength, durability, resistance to corrosion, and ability to withstand extreme conditions.

- Q: Can steel pipes be used for underground electrical conduits?

- Yes, steel pipes can be used for underground electrical conduits. Steel pipes are durable, strong, and resistant to external forces, making them suitable for protecting electrical wiring in underground installations. Additionally, steel pipes offer excellent corrosion resistance, ensuring the longevity and safety of the electrical system.

- Q: What is the role of steel pipes in sewage systems?

- Steel pipes play a crucial role in sewage systems as they are used to transport wastewater and sewage from various sources to treatment plants or disposal areas. Their strength, durability, and resistance to corrosion make them ideal for handling the often harsh and corrosive nature of sewage. Additionally, steel pipes can withstand high pressures and provide a reliable and long-lasting solution for sewage transportation, ensuring the efficient and safe functioning of sewage systems.

- Q: How are steel pipes used in the telecommunications infrastructure?

- Steel pipes are commonly used in telecommunications infrastructure for the installation of underground cables. These pipes provide protection and support to the cables, ensuring their longevity and efficient functioning. Additionally, steel pipes are used for the construction of telecommunication towers, providing a sturdy framework for antennas and other equipment.

- Q: What is the buckling type thin-wall steel pipe? What is a tight set of thin-walled steel tubes? What's the difference between the two?

- The nut body and the junction box are connected at one end by adopting metric fine tooth thread, and the pipe is connected with the pipe, and one end is the same as the straight pipe joint (direct). Withhold the box joint points inside and outside teeth two. The diameter of straight pipe joint is divided into 16mm, 20mm, 25mm, 32mm, 40mm, 50mm.

- Q: How does galvanization protect steel pipes from corrosion?

- Galvanization protects steel pipes from corrosion by applying a protective zinc coating on the surface of the pipes. This zinc coating acts as a sacrificial anode, meaning it corrodes first before the steel, effectively preventing rust and corrosion from reaching the underlying steel.

- Q: How are steel pipes used in the construction of biomass power plants?

- Steel pipes are used in biomass power plants for various applications such as transporting biomass fuel, carrying water for steam generation, and distributing hot water or steam throughout the plant. They provide a sturdy and reliable infrastructure for the efficient functioning of the plant, ensuring the safe and effective operation of the biomass power generation process.

- Q: What are the common welding techniques used for steel pipes?

- The common welding techniques used for steel pipes include shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). These techniques are widely used in various industries for joining steel pipes due to their efficiency, reliability, and ability to produce strong and durable welds.

- Q: What are the standard dimensions and weight of steel pipes?

- The specific type and grade of steel pipes determine the variation in standard dimensions and weight. Nonetheless, the industry widely accepts some common standard dimensions and weight ranges. Seamless steel pipes typically have standard dimensions ranging from 1/8 inch to 60 inches in outer diameter (OD) and from 10.3 mm to 914.4 mm in wall thickness. The weight of seamless steel pipes varies depending on the size and length, ranging from a few kilograms to several metric tons. Similarly, welded steel pipes have standard dimensions ranging from 1/2 inch to 80 inches in OD and from 3.2 mm to 25.4 mm in wall thickness. The weight of welded steel pipes can also greatly vary, ranging from a few kilograms to several metric tons. It is worth noting that the dimensions and weight of steel pipes can be customized according to specific project requirements. Moreover, different countries or regions may have their own standards and specifications for steel pipes. Therefore, it is always advisable to consult the relevant standards and guidelines when determining the dimensions and weight of steel pipes for a particular application.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2005 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 390People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM not offered |

| Product Price Range | Average |

Send your message to us

Carbon Steel Pipes For High Temperature ServiceE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords