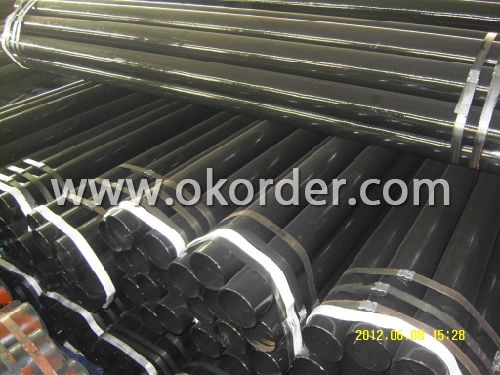

Seamless Steel Pipe For Low Pressure Boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Seamless steel tubes and pipes for low and medium pressure boiler |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: How are steel pipes used in the infrastructure development?

- Steel pipes are widely used in infrastructure development for various purposes. They are commonly used for transporting water, oil, and gas, as well as for drainage systems and sewage networks. Steel pipes are also used in the construction of bridges, buildings, and highways, providing structural support and stability. Additionally, steel pipes are utilized in underground utilities, such as telecommunications and electrical systems. Their durability, strength, and resistance to corrosion make steel pipes a crucial component in infrastructure development.

- Q: What is the maximum length of steel pipes available?

- The maximum length of steel pipes available can vary depending on the specific manufacturer and supplier. However, in general, steel pipes can be found in lengths ranging from 18 feet to 40 feet or even longer.

- Q: How do you calculate the pipe deflection for steel pipes?

- To determine the pipe deflection of steel pipes, various factors must be taken into account. Pipe deflection refers to the bending or displacement that occurs when a load is applied. The following steps outline the process for calculating pipe deflection: 1. Obtain the steel pipe properties: Familiarize yourself with the material properties of the steel pipe, including its Young's modulus (E) and moment of inertia (I). Young's modulus denotes the material's stiffness, while the moment of inertia measures its resistance to bending. 2. Identify the applied load: Determine the nature and magnitude of the load that will be exerted on the pipe. This may encompass internal pressure, external loads, or thermal expansion. 3. Utilize the appropriate formula: Depending on the load type and pipe support conditions, the suitable formula must be employed to calculate the deflection. For instance, if the pipe is simply supported (fixed at both ends), the formula δ = (5 * w * L^4) / (384 * E * I) can be used. Here, δ represents the deflection, w signifies the load per unit length, L denotes the pipe length, and E and I refer to the previously mentioned material properties. 4. Input values and compute: Insert the load, pipe length, and material properties into the formula. By doing so, the deflection of the steel pipe can be determined. It is crucial to note that calculating pipe deflection is a complex procedure that necessitates expertise in structural engineering. Therefore, it is advisable to consult a professional engineer or employ specialized software for accurate and reliable results.

- Q: Will the steel tube dance?

- The steel tube dance tube has a rotating steel tube and a fixed steel tube, so that different types of steel pipe can be chosen according to the type of pipe dance performed by the dancer.

- Q: Can steel pipes be used for water distribution networks?

- Yes, steel pipes can be used for water distribution networks. Steel pipes are commonly used for water distribution due to their durability, strength, and resistance to corrosion. They can efficiently handle high water pressure and are suitable for both underground and above-ground installations. However, proper protective coatings are necessary to prevent rusting and maintain water quality.

- Q: What are the dimensions of a standard steel pipe?

- The dimensions of a standard steel pipe can vary depending on its intended use, but common dimensions include a nominal size (such as 1/2 inch, 1 inch, 2 inches, etc.) and a schedule number indicating its wall thickness (such as Schedule 40 or Schedule 80). The outside diameter of the pipe can range from small sizes of less than half an inch to large sizes of several feet. The length of a standard steel pipe is typically 21 feet, although shorter lengths are also available.

- Q: What is the difference between steel pipe and HDPE pipe?

- Steel pipe and HDPE pipe are two different types of pipes that are used for various applications. The main difference between steel pipe and HDPE pipe lies in their composition and characteristics. Steel pipe, as the name suggests, is made of steel and is a strong and durable pipe material. It is commonly used in industrial applications and infrastructure projects where high strength and reliability are required. Steel pipes are known for their ability to withstand high pressure, temperature, and heavy loads. They are also resistant to corrosion, making them suitable for both above-ground and underground installations. On the other hand, HDPE (high-density polyethylene) pipe is made of a plastic polymer called polyethylene. HDPE pipes are lightweight, flexible, and easy to install, making them ideal for various applications such as water supply, drainage systems, and agricultural irrigation. They are resistant to chemicals, abrasion, and UV rays, making them suitable for both indoor and outdoor use. HDPE pipes are also known for their long service life and low maintenance requirements. In terms of cost, steel pipes are generally more expensive than HDPE pipes due to the raw material cost and manufacturing process involved. However, steel pipes are often chosen for their superior strength and durability, especially in applications where high pressure or extreme conditions are involved. HDPE pipes, on the other hand, offer a cost-effective solution for applications that do not require the same level of strength and durability as steel pipes. In summary, the main differences between steel pipe and HDPE pipe lie in their composition, strength, durability, and cost. Steel pipe is known for its strength and reliability, while HDPE pipe offers flexibility, ease of installation, and resistance to chemicals and UV rays. The choice between the two depends on the specific application and requirements of the project.

- Q: How are steel pipes used in high-rise buildings?

- Steel pipes are commonly used in high-rise buildings for various purposes. They are primarily used for structural support as they provide strength and durability, allowing the building to withstand the vertical loads and forces that occur due to its height. Steel pipes are also used for plumbing systems, carrying water and other fluids throughout the building. Additionally, they can be used for HVAC systems, providing ventilation and air conditioning to each floor. Overall, steel pipes are integral components in high-rise buildings, ensuring the safety, functionality, and comfort of the occupants.

- Q: What is the hardness of steel pipes?

- The specific grade and manufacturing process can cause the hardness of steel pipes to vary. Generally, alloys are used to make steel pipes, which offer a combination of strength and toughness. To determine the hardness of steel pipes, different methods like Rockwell or Brinell hardness tests can be carried out. These tests gauge the steel's resistance to indentation or penetration using a standardized indenter. The hardness of steel pipes is usually represented as a numerical value on a scale, like the Rockwell hardness scale (e.g., HRC or HRB) or the Brinell hardness scale (e.g., HB). The hardness of steel pipes is significant as it indicates their capacity to endure physical stresses, such as pressure, impact, or wear, in various applications such as construction, oil and gas transportation, and manufacturing.

- Q: How do steel pipes handle abrasive materials?

- Steel pipes are highly resistant to abrasion and can effectively handle abrasive materials. The durable nature of steel allows it to withstand the erosive forces caused by abrasive particles, preventing damage and maintaining structural integrity. Additionally, steel pipes can be further protected by applying coatings or linings, enhancing their ability to handle even the most abrasive substances.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1992 |

| Annual Output Value | 60,000Tons |

| Main Markets | Europe and the United States;Canada; India;Bulgaria; South Korea;etc. |

| Company Certifications | API 5L;API 5CT;GB/T19001-2008 idt ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Yan Cheng |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 400-500 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 110,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Seamless Steel Pipe For Low Pressure Boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords