America Welded Black ERW Steel Tube A500 ASTM A53

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

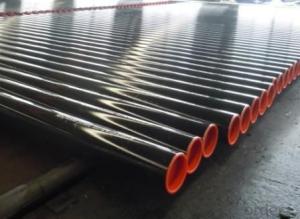

1、Structure of America Welded Black ERW Steel Tube A500 ASTM A53 :

America Welded Black ERW Steel Tube A500 ASTM A53 is electric resistance welding, the abbreviation for ERW for transporting oil and natural gas vapor liquid objects, can meet the requirements of high and low pressure, the transport in the world with pipe sector accounted for a pivotal position.With sound reputation and high quality , we will offer clients a wonderful business experience.

2、Main Features of America Welded Black ERW Steel Tube A500 ASTM A53 :

• High manufacturing accuracy

• High strength

• Good visual effect

• Good view and appearance

• Good shape

• Reasonable price

• Small inertia resistance

• Strong heat dissipation ability

3、America Welded Black ERW Steel Tube A500 ASTM A53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of America Welded Black ERW Steel Tube A500 ASTM A53 :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、 America Welded Black ERW Steel Tube A500 ASTM A53 Images:

- Q: Can steel pipes be used for cooling systems?

- Yes, steel pipes can be used for cooling systems. Steel pipes are commonly used in various industrial cooling applications due to their durability, high strength, resistance to corrosion, and ability to withstand high pressure and temperature conditions.

- Q: Is steel pipe made of profiles?

- Large steel: large steel, I-beam, channel steel, angle steel and flat steel are hot rolled, round bar, Fang Gang, six angle iron in addition to hot rolling, there are forging, cold drawn and so on.

- Q: Are steel pipes resistant to UV radiation?

- Yes, steel pipes are generally resistant to UV radiation. UV radiation is known to cause damage to materials over time, such as fading, discoloration, and degradation. However, steel pipes are typically coated with protective layers, such as paint or galvanization, which help to shield them from UV radiation. These coatings act as a barrier, preventing the direct exposure of steel to UV rays and minimizing the potential for damage. Additionally, the inherent properties of steel, including its strength and durability, make it less susceptible to the effects of UV radiation compared to other materials like plastics or rubber. However, it is important to note that prolonged exposure to intense UV radiation can still have some impact on steel pipes, such as slight discoloration or surface degradation. Regular maintenance and inspection are recommended to ensure the continued performance and longevity of steel pipes in outdoor or UV-exposed environments.

- Q: Can steel pipes be used for conveying sewage sludge?

- Indeed, sewage sludge can be conveyed using steel pipes. Steel pipes possess several properties that render them suitable for this purpose. Firstly, their strength and durability enable them to endure the pressure and weight of sewage sludge without collapsing or fracturing. This is of utmost importance as sewage sludge can be quite heavy and may contain solids that could exert stress on the pipes. Secondly, steel pipes exhibit resistance to corrosion, which is crucial when conveying sewage sludge that frequently contains corrosive components. By utilizing corrosion-resistant steel pipes, one can ensure a prolonged lifespan and minimize the risk of leaks or damage. Moreover, steel pipes can be manufactured in various sizes and diameters, granting flexibility in the design of sewage systems to meet specific requirements. Nonetheless, it is vital to emphasize the necessity of proper maintenance and regular cleaning to prevent sludge buildup and maintain the pipes' efficiency.

- Q: What are the different methods of cleaning steel pipes?

- There are several methods of cleaning steel pipes, including mechanical cleaning, chemical cleaning, and high-pressure water jetting. Mechanical cleaning involves the use of brushes, scrapers, or other abrasive tools to remove dirt and debris from the pipe's surface. Chemical cleaning involves the application of solvents or acids to dissolve tough stains or residues. High-pressure water jetting uses a powerful stream of water to dislodge and remove contaminants from the pipe. These methods can be used individually or in combination depending on the specific cleaning requirements.

- Q: Can steel pipes be bent?

- Yes, steel pipes can be bent using specialized tools and techniques such as pipe bending machines or hydraulic benders.

- Q: What is the abrasion resistance of steel pipes?

- Steel pipes have a relatively high resistance to abrasion. They possess exceptional strength and durability, rendering them resilient against the detrimental effects of friction and impact. This quality positions steel pipes as a prime option for various industries and applications that frequently encounter abrasion, such as mining, oil and gas, and the transportation of abrasive substances. Furthermore, steel pipes can be fortified with coatings or linings to enhance their resistance against abrasion, tailored to meet the unique demands of each application. In conclusion, steel pipes present a dependable and enduring solution for effectively managing abrasive materials and environments.

- Q: Can steel pipes be painted?

- Yes, steel pipes can be painted. The process typically involves cleaning and preparing the surface, applying a primer, and then using a suitable paint or coating to achieve the desired finish.

- Q: What are the different grades of steel used in pipe manufacturing?

- There are various grades of steel used in pipe manufacturing, including carbon steel, alloy steel, stainless steel, and duplex steel.

- Q: How are steel pipes classified based on their wall thickness?

- Steel pipes are classified based on their wall thickness into three categories: standard, extra strong, and double extra strong.

Send your message to us

America Welded Black ERW Steel Tube A500 ASTM A53

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords