Schedule 40 Seamless Carbon Steel Pipe API P110 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

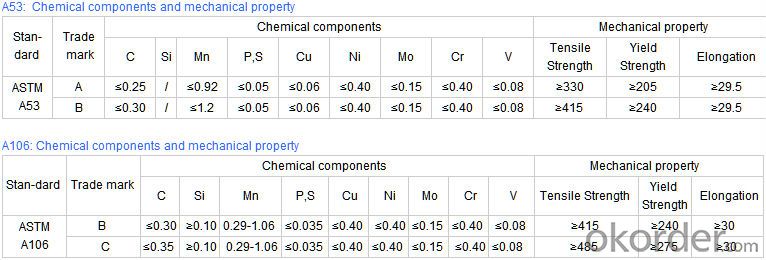

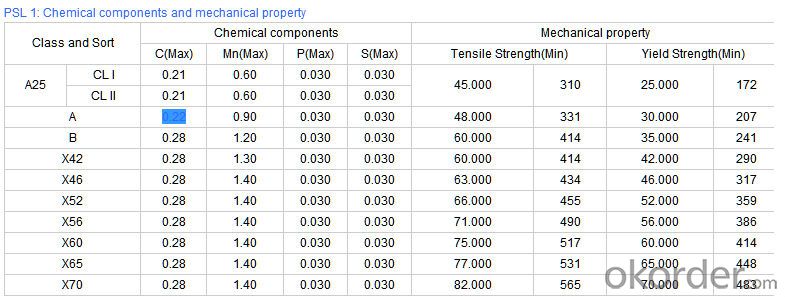

Technical Parameters of Seamless Steel Pipe

- Q: Can steel pipes be used for oil drilling operations?

- Yes, steel pipes are commonly used for oil drilling operations due to their strength, durability, and ability to withstand high pressure and corrosive environments.

- Q: How are steel pipes used in hydroelectric power plants?

- Steel pipes are used in hydroelectric power plants to transport water from the reservoir to the turbines. These pipes are able to withstand high pressure and ensure a reliable flow of water, which is crucial for the efficient operation of the turbines. Additionally, steel pipes are also used for the construction of penstocks, which control the flow of water and direct it towards the turbines.

- Q: What is the difference between steel pipe and copper pipe?

- The main difference between steel pipe and copper pipe lies in their material composition. Steel pipe is made of steel, while copper pipe is made of copper. Steel pipe is stronger and more durable, making it suitable for high-pressure and heavy-duty applications. On the other hand, copper pipe is more malleable and corrosion-resistant, making it ideal for plumbing and water supply systems. Additionally, copper pipe is more expensive than steel pipe but offers better heat conductivity, making it suitable for heating and cooling applications.

- Q: Can steel pipes be used for desalination plants?

- Yes, steel pipes can be used for desalination plants. Steel is often chosen for its high strength, durability, and resistance to corrosion, making it suitable for carrying and transporting the highly saline water used in desalination processes. Additionally, steel pipes can handle high pressure, ensuring efficient water flow throughout the plant.

- Q: Can steel pipes withstand high temperatures?

- Yes, steel pipes can withstand high temperatures. Steel is a strong and durable material that has high heat resistance. It can retain its strength and structural integrity even when exposed to extreme heat, making it suitable for various high-temperature applications such as industrial furnaces, power plants, and steam pipelines.

- Q: How are steel pipes used in the wastewater treatment industry?

- Steel pipes are commonly used in the wastewater treatment industry for various purposes such as carrying and distributing wastewater, transporting chemicals, and constructing infrastructure like tanks, pumps, and treatment units. The strength, durability, and corrosion resistance of steel pipes make them ideal for handling the harsh and corrosive nature of wastewater, ensuring efficient and reliable operation of the treatment processes.

- Q: Are steel pipes resistant to earthquakes?

- Compared to other materials like concrete or PVC pipes, steel pipes are commonly regarded as more resistant to earthquakes. This is because steel possesses inherent properties such as high tensile strength and flexibility. These properties enable steel pipes to effectively absorb and distribute seismic energy during an earthquake, enabling them to endure shaking and ground movements more effectively. Moreover, steel pipes have the capability to deform without rupturing or collapsing, reducing the risk of structural failure. However, it is crucial to note that the earthquake resistance of steel pipes ultimately relies on various factors including the design, installation, and overall structural integrity of the piping system. To ensure the highest level of earthquake resistance for steel pipes, it is imperative to adhere to proper engineering and construction practices.

- Q: How do you repair a damaged steel pipe?

- To repair a damaged steel pipe, you can follow a few steps. First, identify the extent of the damage, such as cracks or holes. Next, clean the damaged area using a wire brush or sandpaper to remove any rust, debris, or old paint. Then, apply a suitable epoxy or sealing compound to seal the crack or hole. For larger damages, welding or brazing may be necessary. Finally, ensure the repaired area is dry and properly cured before testing the pipe for leaks or further issues.

- Q: How do you remove rust from steel pipes?

- To remove rust from steel pipes, there are several methods you can try: 1. Use a wire brush or steel wool: Start by scrubbing the rusted areas with a wire brush or steel wool. This will help remove loose rust and flakes from the surface of the pipes. 2. Apply vinegar or lemon juice: Soak a cloth or sponge in white vinegar or lemon juice and apply it to the rusted areas. Let it sit for a few hours or overnight. The acidic properties of these substances can help dissolve the rust. 3. Use a rust remover or converter: There are various rust remover products available in the market. Follow the instructions on the product and apply it to the rusted areas. These solutions typically convert rust into a water-soluble compound that can be easily rinsed off. 4. Apply a paste of baking soda and water: Mix baking soda with water to create a thick paste. Apply the paste to the rusted areas and let it sit for a few hours. Scrub the area using a brush or steel wool, and then rinse it off. 5. Try using a commercial rust dissolver: If the above methods don't yield satisfactory results, you can consider using a commercial rust dissolver. These products are specifically designed to remove rust from various surfaces, including steel pipes. Follow the instructions provided by the manufacturer. Remember to wear protective gloves, goggles, and a mask when working with rust removal products, as they can be corrosive or release toxic fumes. Additionally, after removing rust, it is advisable to apply a rust-inhibiting primer or paint to prevent future rusting.

- Q: Are steel pipes suitable for use in mining applications?

- Yes, steel pipes are suitable for use in mining applications. Steel pipes are known for their high durability, strength, and resistance to corrosion, making them ideal for mining operations where they may be exposed to harsh conditions such as abrasive materials, high pressure, and extreme temperatures. Additionally, steel pipes can be easily welded and customized to meet specific mining requirements, making them a reliable choice for transporting fluids, gases, and materials in mining operations.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe API P110 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords