Structure of Seamless A192-02 Standard Steel Pipe ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless A192-02 Standard Steel Pipe ASTM :

Seamless A192-02 Standard Steel Pipe ASTM is to be used for conveying gas, water, and petroleum foroil and natural gas industries. And used for structural steel pies purpose . It can meet the requirements of high and low pressure, the transport in the world with pipe sector accounted for a pivotal position.As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Seamless A192-02 Standard Steel Pipe ASTM :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless A192-02 Standard Steel Pipe ASTM ,Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM SPEC 5CT-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless A192-02 Standard Steel Pipe ASTM :

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

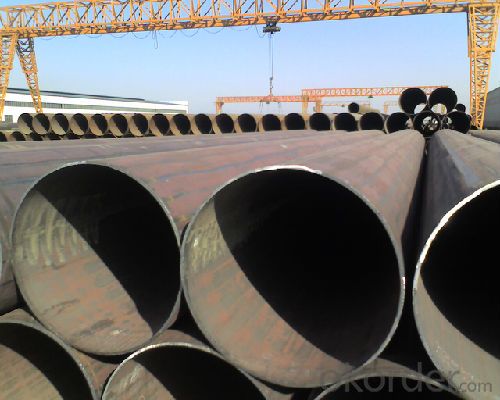

6、 Seamless A192-02 Standard Steel Pipe ASTM : Images:

- Q: Can steel pipes be used for underground cable conduits?

- Yes, steel pipes can be used for underground cable conduits.

- Q: How do you repair damaged steel pipes?

- To repair damaged steel pipes, the first step is to assess the extent of the damage. If it's a small crack or hole, it can be fixed using a steel-filled epoxy or a pipe repair clamp. However, for more significant damage, such as extensive corrosion or a large rupture, cutting out the damaged section and replacing it with a new pipe is usually necessary. In some cases, professional welding or soldering may be required to ensure a secure and leak-proof repair.

- Q: How are steel pipes protected against chemical corrosion?

- Steel pipes are protected against chemical corrosion through various methods such as applying protective coatings like epoxy or polyethylene, using sacrificial anodes, cathodic protection systems, or employing corrosion inhibitors in the pipeline system.

- Q: What is the outer diameter of the steel tube?

- The outer diameter refers to the maximum diameter including the thickness of the steel tube, the inner diameter is the length of the hollow part inside, and the outer diameter minus the inside diameter is the thickness of the steel pipe

- Q: How are steel pipes protected from corrosion?

- Steel pipes are protected from corrosion through various methods such as applying protective coatings like paint or epoxy, galvanization, and cathodic protection. These measures create a barrier between the steel surface and corrosive elements to prevent the pipes from rusting and deteriorating.

- Q: What is the difference between hot-dipped galvanized and electro-galvanized steel pipes?

- Hot-dipped galvanized steel pipes are coated with a thick layer of zinc by immersing them in a bath of molten zinc, creating a durable and corrosion-resistant coating. On the other hand, electro-galvanized steel pipes are coated with a thinner layer of zinc through an electroplating process, offering a more economical and aesthetically pleasing option.

- Q: What are the different grades of steel used in pipe manufacturing?

- The different grades of steel used in pipe manufacturing vary depending on the intended use and specific requirements. Some common grades include carbon steel (such as ASTM A106 or API 5L), alloy steel (such as ASTM A335), stainless steel (such as ASTM A312), and duplex steel (such as ASTM A790). These grades have different chemical compositions and mechanical properties to suit various applications in industries like oil and gas, construction, and plumbing.

- Q: How are steel pipes protected against fire?

- Steel pipes are typically protected against fire through the application of fire-resistant coatings or by encasing them in fire-rated materials, such as concrete or gypsum board. Additionally, fire sprinkler systems or fire-resistant insulation may be installed around the pipes to provide an added layer of protection.

- Q: Are steel pipes suitable for high-pressure applications?

- Yes, steel pipes are suitable for high-pressure applications. Steel pipes are known for their strength and durability, making them ideal for handling high-pressure applications. They can withstand the internal pressure exerted by fluids or gases under high pressure without deforming or bursting. The high tensile strength of steel allows it to resist the forces that occur in high-pressure environments, ensuring the safety and reliability of the piping system. Additionally, steel pipes can be manufactured with thicker walls to further enhance their ability to withstand high pressures. Steel pipes are widely used in industries such as oil and gas, petrochemical, power generation, and water distribution, where high-pressure applications are common.

- Q: Can steel pipes be used for transporting chemicals?

- Yes, steel pipes can be used for transporting chemicals. Steel pipes are known for their high strength and durability, making them suitable for handling various chemicals, including corrosive substances. Additionally, steel pipes can withstand high pressure and temperature conditions, ensuring the safe transportation of chemicals. However, it is essential to select the appropriate grade of steel and implement proper coating or lining to prevent chemical reactions or corrosion that may compromise the integrity of the pipes.

Send your message to us

Structure of Seamless A192-02 Standard Steel Pipe ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords