Schedule 40 Seamless Carbon Steel Pipe 15CrMoG CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

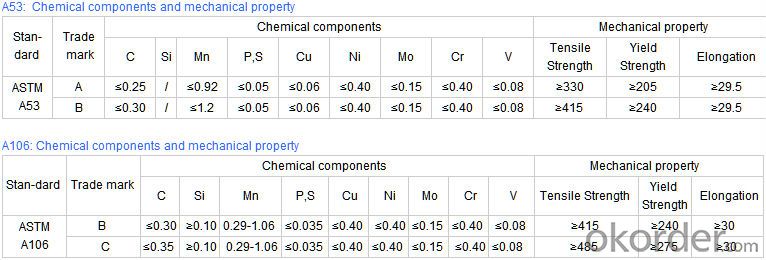

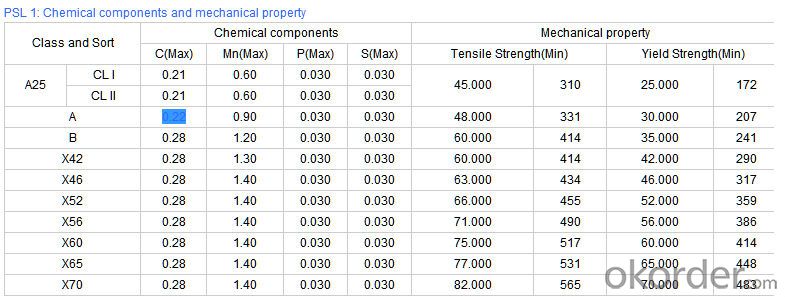

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: How are steel pipes used in the manufacturing of chemical processing plants?

- Steel pipes are commonly used in chemical processing plants for various purposes such as transporting fluids, gases, and chemicals within the facility. They are utilized for the safe and efficient transfer of raw materials, intermediate products, and final products throughout different stages of the manufacturing process. Steel pipes provide excellent strength, durability, and resistance to corrosion, making them suitable for handling corrosive materials and operating under high pressure and temperature conditions. Additionally, steel pipes can be welded and connected easily, allowing for customized configurations and efficient installation in chemical processing plants.

- Q: What type of steel pipe for security windows?

- Stainless steel security window generally use 25 square tubes and 19 round tubes! 25/38 tubes and 22 round tubes are also available!

- Q: Are steel pipes suitable for use in hydropower plants?

- Yes, steel pipes are suitable for use in hydropower plants. Steel pipes offer several advantages such as high strength, durability, and corrosion resistance, making them ideal for transporting water or fluids in hydropower plants. Additionally, steel pipes can withstand high pressure and temperature conditions, ensuring smooth and efficient operation of the hydropower plant.

- Q: What's the difference between steel pipe and pipe fittings?

- Steel: steel pipe is a hollow steel strip, used as pipe conveying fluid, such as oil, gas, water, gas, steam, in addition, the bending and torsional strength of the same, the weight is light, so it is widely used in the manufacture of machinery parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: How are steel pipes used in seaport infrastructure?

- Steel pipes are extensively used in seaport infrastructure for various purposes such as constructing piers, offshore platforms, and docking facilities. They are commonly used for building underwater foundations, pilings, and support structures that provide stability and strength to the port infrastructure. Steel pipes are also used in the construction of pipelines, drainage systems, and water supply networks within the seaport, ensuring efficient transportation of goods and materials. Overall, steel pipes play a crucial role in maintaining the structural integrity and functionality of seaport infrastructure.

- Q: How are steel pipes used in structural applications?

- Steel pipes are commonly used in structural applications due to their strength, durability, and versatility. They are often used as columns, beams, and braces in buildings, bridges, and other structures. Steel pipes provide excellent load-bearing capacity and can withstand high levels of stress and pressure, making them ideal for supporting heavy loads. Additionally, their hollow cylindrical shape allows for easy installation and provides space for utilities such as electrical wiring or plumbing. Overall, steel pipes contribute to the stability and integrity of structures, ensuring their safety and longevity.

- Q: Are steel pipes resistant to chemicals and corrosion?

- Yes, steel pipes are generally resistant to chemicals and corrosion.

- Q: Are steel pipes suitable for conveying fluids?

- Yes, steel pipes are suitable for conveying fluids. Steel pipes have been widely used in various industries for many years due to their durability, strength, and resistance to corrosion. These qualities make steel pipes an ideal choice for conveying fluids such as water, oil, gas, and even hazardous chemicals. The smooth interior surface of steel pipes also allows for efficient flow and prevents clogging, making them suitable for applications that require a continuous and smooth flow of fluids. Furthermore, steel pipes can withstand high pressure and temperature conditions, making them suitable for both high and low-pressure fluid transmission systems. Overall, steel pipes are a reliable and efficient option for conveying fluids in a wide range of industries, including oil and gas, water treatment, chemical processing, and many more.

- Q: How are steel pipes used in oil refineries?

- Steel pipes are extensively used in oil refineries for various purposes such as transporting crude oil, refined products, and gases throughout the facility. They are used in the construction of pipelines, process equipment, and storage tanks, providing a reliable and durable solution for handling the vast quantities of liquids and gases involved in the refining process.

- Q: What is the difference between steel pipes and fiberglass-reinforced pipes?

- The main difference between steel pipes and fiberglass-reinforced pipes lies in their composition and structural characteristics. Steel pipes are made of a durable metal alloy, typically carbon steel, which provides strength and resistance to high pressure and temperature. On the other hand, fiberglass-reinforced pipes are composed of a plastic matrix reinforced with glass fibers, making them lightweight, corrosion-resistant, and suitable for various applications. While steel pipes are commonly used in industrial settings, fiberglass-reinforced pipes are often utilized in sectors requiring corrosion resistance, such as chemical processing, wastewater treatment, and oil and gas industries.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 15CrMoG CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords