Schedule 40 Seamless Carbon Steel Pipe 12Cr1MoVG CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

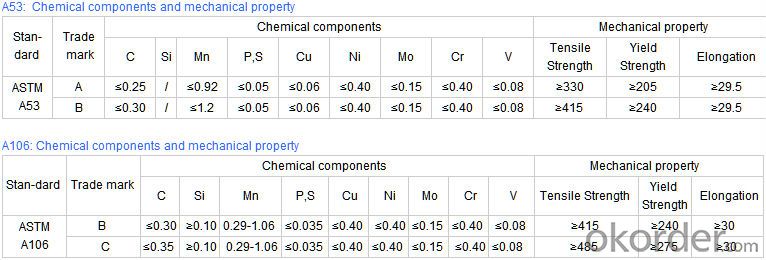

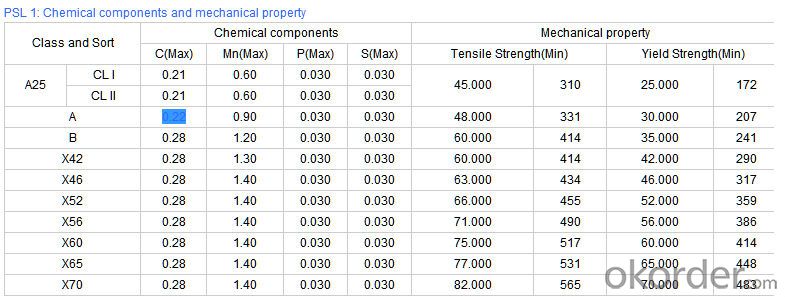

Technical Parameters of Seamless Steel Pipe

- Q: Are steel pipes affected by UV rays?

- Yes, steel pipes can be affected by UV rays. Over time, exposure to UV radiation can cause the steel to degrade and weaken. It can lead to surface oxidation, discoloration, and in extreme cases, structural damage. To prevent this, protective coatings or paint can be applied to shield the steel pipes from UV rays.

- Q: How are steel pipes tested for mechanical strength?

- Steel pipes are tested for mechanical strength through various methods such as tensile testing, hydrostatic testing, and non-destructive testing. Tensile testing involves pulling the pipe until it breaks to measure its ultimate tensile strength. Hydrostatic testing involves pressurizing the pipe with water to check its ability to withstand high internal pressures. Non-destructive testing methods like ultrasonic testing or magnetic particle inspection are also used to detect any defects or weaknesses in the pipe without causing damage. These tests ensure that steel pipes are strong enough to withstand the required mechanical stresses.

- Q: Can steel pipes be used for hydronic heating systems?

- Yes, steel pipes can be used for hydronic heating systems. Steel pipes are commonly used in hydronic heating systems due to their durability, strength, and ability to withstand high temperatures and pressure. They are also resistant to corrosion, which is important for maintaining the efficiency and longevity of the heating system. However, it is essential to ensure proper insulation and protection against potential expansion and contraction issues that steel pipes may face when exposed to high temperatures.

- Q: How are steel pipes inspected for defects?

- Steel pipes are inspected for defects using various methods, including visual inspection, ultrasonic testing, magnetic particle inspection, dye penetrant testing, and radiographic examination. These techniques help identify any cracks, corrosion, or other defects in the pipes to ensure their structural integrity and prevent any potential hazards or failures.

- Q: How are steel pipes used in the manufacturing of marine applications?

- Steel pipes are commonly used in the manufacturing of marine applications due to their durability, strength, and resistance to corrosion. They play a crucial role in various applications such as shipbuilding, offshore platforms, and underwater pipelines. Steel pipes are used to transport fluids, gases, and oils, as well as for structural support and protection against harsh marine environments. Additionally, steel pipes are also utilized in the construction of marine heat exchangers and cooling systems.

- Q: Can steel pipes be used for scaffolding and support structures?

- Indeed, scaffolding and support structures can make use of steel pipes. Due to their robustness, longevity, and ability to bear substantial loads, steel pipes are commonly employed in the construction industry. They establish a steady and secure framework for scaffolding and support structures, guaranteeing the safety of workers and the stability of the construction undertaking. Moreover, steel pipes possess versatility, enabling convenient assembly and disassembly, rendering them a superb option for temporary structures such as scaffolding. Furthermore, steel pipes exhibit resistance to corrosion, rendering them appropriate for outdoor applications and ensuring the enduring existence of the scaffolding and support structures.

- Q: What are the common applications of steel pipes?

- Steel pipes have a wide range of common applications, including plumbing systems, transportation of liquids and gases, construction projects, oil and gas exploration, as well as in industrial processes such as manufacturing and power generation.

- Q: Galvanized steel pipe in addition to good rust resistance, what are the advantages?

- Because the zinc has been plated outside the steel tube, the time for oiling or painting outside is omitted, and the construction is more convenient;

- Q: How are steel pipes protected against corrosion in marine environments?

- Steel pipes are protected against corrosion in marine environments through various methods, including the use of protective coatings, cathodic protection systems, and selecting corrosion-resistant materials.

- Q: What is the difference between internal threading and external threading of steel pipes?

- Internal threading and external threading are two different methods used to create threads on steel pipes. The main difference between them lies in the location of the threads. Internal threading refers to the process of cutting threads on the inside surface of a steel pipe. This method involves using a tool or a die to remove material from the inner diameter of the pipe, creating a helical groove. The resulting threads can be used to connect the pipe to other components, such as fittings or valves. On the other hand, external threading involves cutting threads on the outside surface of a steel pipe. This process usually requires the use of a threading die or a lathe to remove material from the outer diameter of the pipe, leaving behind a helical groove. The external threads allow the pipe to be connected to other components or fittings that have corresponding internal threads. The choice between internal and external threading depends on the specific application and the requirements of the project. Internal threading is often preferred when the pipe needs to be connected to components that have external threads, such as fittings or valves. External threading, on the other hand, is typically used when the pipe needs to be connected to components with internal threads, or when the pipe is intended to be screwed into a threaded hole or coupling. In summary, the main difference between internal threading and external threading of steel pipes is the location of the threads – internal threads are cut on the inside surface of the pipe, while external threads are cut on the outside surface. The choice between these methods depends on the specific application and the type of connections required.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 12Cr1MoVG CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords