SBS Elastomeric Bitumen Waterproof Roofing Membrane Adhensive

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

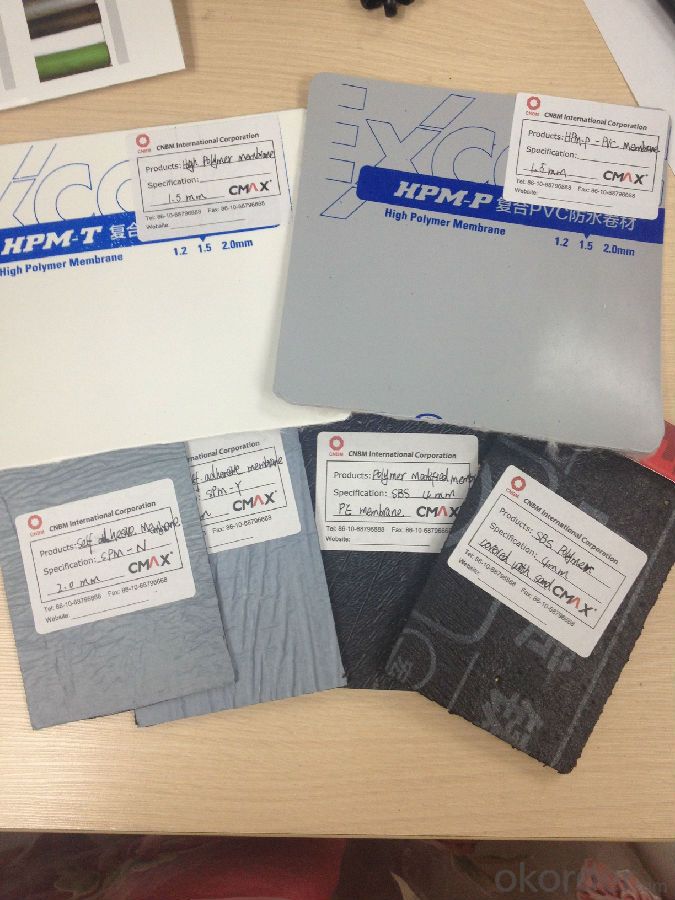

Quick DetailsType:

Waterproof Membrane, Waterproof membrane Place of Origin: China (Mainland)

Surface film: PE, SAND, SCHIST,aluminum Thickness: 2.0mm~5.0mm Length: 10.0m

Width: 1.0m Usage: waterproofing for roof, understand,etc

Packaging & DeliveryPackaging Details: 10 sq.m./roll export package or as requirment

Delivery Detail: 15 days after receipt of deposit.

Specifications3mm SBS modified bitumen waterproof membrane

1) 2--5mm

2) Base:PY/G

3) Surface:PE / S / M / Al

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. start application till it is dry.< span="">

2. Application Method:

Heating the bottom surface of membrane and the roof deck surface by flam spray gun or other suitable appliances till the asphalt start to melt(not flowing), then spread. Using roller to compact the membrane so that it can firmly adhere to the base surface. The overlap on the long side should be 100mm and the short side should be 150mm.

3. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

Package

Attentions for Construction

·

SBS / APP asphalt waterproof membrane, bituminous waterproof membrane

1. Membranes should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away

from sunshine and rainwater.

Installation Sketch point

Clean the substrate using broom or high pressure dusty cleaner.

Apply primer

Heat the membrane bottom using a high temperature flame gun.

Push forward while the primer and membrane oil melted

Use a roller to push hard the membrane surface to ensure it stick firmly

Application is named as "Torched on application".

1.Base processing: the base surface musts be clean,solid,level,dry;no grit,rift and loosing dust. For a large recess, fill it with cement mortar and then level it. Remove the protrusion and clean dust If working on base slab or lateral face,water lowering should be done.

2.Painting primer before laying the membrane, clean the dust on the surface of concrete base with dust catcher or dust-blower; then paint entirely with treatment agent of DY primer for waterproofing(for purpose of dust consolidation and high adhesive effect).

3.Heat to melt: place membrane correctly, fire torch, heat the membrane with base entirely, when the surface of the membrane is black and bright with a fusion layer, apply the membrane and press it into a solid and flat state.Before the membrane is cool, seal the edge of joint by float.

4.Requirements for lapping: There should be less than 3 layers of lapping, with the joint seams appearing as"T" type,avoid 4 layers of lapping.The width of longitudinal lapping is between 50 and 80mm,and of end-lap joint 100mm

- Q: What are the benefits of using a waterproofing membrane?

- The benefits of using a waterproofing membrane include protecting the structure from water damage, preventing leaks and seepage, extending the lifespan of the building, reducing maintenance and repair costs, and creating a healthier and more comfortable environment by preventing mold and mildew growth.

- Q: Can a waterproofing membrane be applied over cracks or joints in a surface?

- Yes, a waterproofing membrane can be applied over cracks or joints in a surface. In fact, it is often recommended to do so in order to ensure a complete and effective waterproofing system. The membrane acts as a barrier that prevents water from seeping through the cracks or joints and causing damage to the underlying structure. However, it is important to note that the cracks or joints should be properly repaired and prepared before applying the waterproofing membrane. This may involve cleaning, filling, and sealing the cracks or joints to ensure that the membrane adheres properly and provides a continuous and watertight seal. Additionally, the type of waterproofing membrane used should be selected based on the specific requirements and conditions of the surface being treated.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Indeed, wastewater treatment plants and sewage facilities require protection against water infiltration and leakage due to the abundance of water and potentially corrosive substances. To address this issue, a versatile solution in the form of a waterproofing membrane can be utilized. This membrane acts as a barrier, preventing water penetration and safeguarding the structure from damage while ensuring the facility's proper functioning. Its application extends to various areas such as walls, floors, roofs, and tanks, effectively maintaining a watertight environment and prolonging the facility's lifespan. Moreover, certain waterproofing membranes are specifically engineered to withstand harsh chemicals, making them ideal for wastewater treatment plants and sewage facilities where corrosive substances may be present.

- Q: Can a waterproofing membrane be used on brick walls?

- Brick walls, being porous, can absorb water and moisture, leading to damage and deterioration. To combat this, a waterproofing membrane can be applied. This membrane acts as a barrier, preventing water from entering the bricks while still allowing moisture to evaporate. By keeping the bricks dry, it reduces the risk of issues like efflorescence, mold, and mildew. Additionally, it improves the thermal insulation of the walls, reducing heat loss and enhancing energy efficiency. It is crucial to select a waterproofing membrane specifically made for masonry surfaces to ensure proper adhesion and long-lasting protection.

- Q: Can a waterproofing membrane be used for water fountains or decorative features?

- Water fountains and decorative features can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a protective barrier against water penetration and can be applied to various surfaces, including those found in water fountains and decorative features. The materials used to make these membranes, such as rubber, bitumen, or liquid-applied coatings, possess excellent waterproofing properties. By applying a waterproofing membrane, you can effectively prevent water from infiltrating the underlying structure and causing damage. This is particularly crucial for water fountains and decorative features, as they are constantly exposed to water. Moreover, waterproofing membranes can also play a role in averting leaks, cracks, and other potential issues that may arise from water exposure, thereby extending the lifespan of the fountain or decorative feature.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic or vehicle loadings?

- In high-traffic or heavy loading areas, it is possible to utilize a waterproofing membrane. Nevertheless, it is crucial to select a membrane specifically designed for such purposes in order to guarantee durability and longevity. These specialized membranes are typically thicker and more resistant to wear and tear. Furthermore, it is important to consider the type of traffic or loading that the area will endure. For instance, areas with vehicular traffic may necessitate a membrane with higher compressive strength to endure the weight of vehicles. In conclusion, the selection of the appropriate type of membrane that satisfies the specific demands of the application is of utmost importance when using waterproofing membranes in high-traffic or heavy loading areas.

- Q: Can a waterproofing membrane be used on drywall surfaces?

- Indeed, it is possible to utilize a waterproofing membrane on surfaces composed of drywall. Drywall, being a material with porosity, is prone to damage caused by moisture, particularly in areas that are inclined to high levels of humidity or exposure to water, such as bathrooms or basements. The application of a waterproofing membrane on drywall aids in the creation of a protective barrier against moisture, thereby preventing the infiltration of water and potential harm. This membrane can be implemented either as a liquid coating or as a sheet membrane directly applied onto the drywall surface. It is of utmost importance to adhere to the instructions provided by the manufacturer and guarantee a proper installation, as this will result in effective waterproofing and safeguard the drywall from issues associated with moisture, such as the growth of mold, mildew, and rot.

- Q: Can a waterproofing membrane withstand heavy rain or water pressure?

- Yes, a waterproofing membrane is designed to withstand heavy rain and high water pressure. It is specifically engineered to create a barrier that prevents water from penetrating through, ensuring the protection and integrity of the underlying structure.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- When installing a waterproofing membrane, there are various safety precautions to consider. To begin with, it is crucial to ensure that the installation team uses all necessary personal protective equipment (PPE). This may incorporate gloves, safety glasses, and appropriate footwear to prevent injuries or exposure to dangerous substances. Moreover, it is essential to work in a well-ventilated area to avoid inhaling fumes or vapors emitted during the installation process. If working in a confined space, it is necessary to take proper measures to guarantee sufficient ventilation and use suitable respiratory protection if needed. Furthermore, it is vital to adhere to the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This involves understanding any potential hazards linked with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to make sure that the installation area is appropriately prepared before commencing the process. This might entail clearing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and easily accessible first aid kits in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to promptly identify and address any potential safety risks. By adhering to these safety precautions, the installation of a waterproofing membrane can be carried out securely and effectively, minimizing the risk of accidents or injuries.

- Q: Can waterproofing membranes be used on roofs?

- Yes, waterproofing membranes can be used on roofs. These membranes are designed to provide a barrier against water infiltration, protecting the roof structure and preventing leaks. They are commonly used in various types of roofs, including flat roofs, low-slope roofs, and even sloped roofs in certain cases. Waterproofing membranes offer excellent durability and flexibility, making them an effective solution for roof waterproofing.

Send your message to us

SBS Elastomeric Bitumen Waterproof Roofing Membrane Adhensive

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords