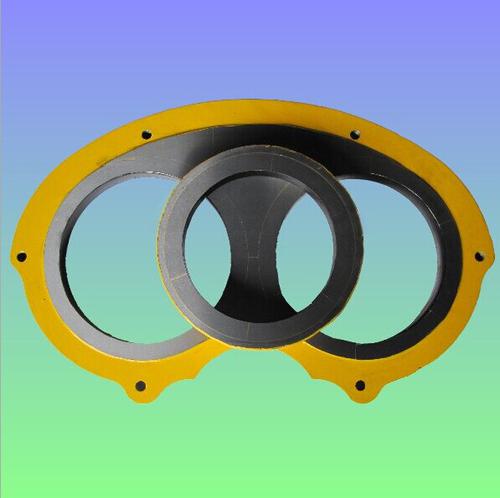

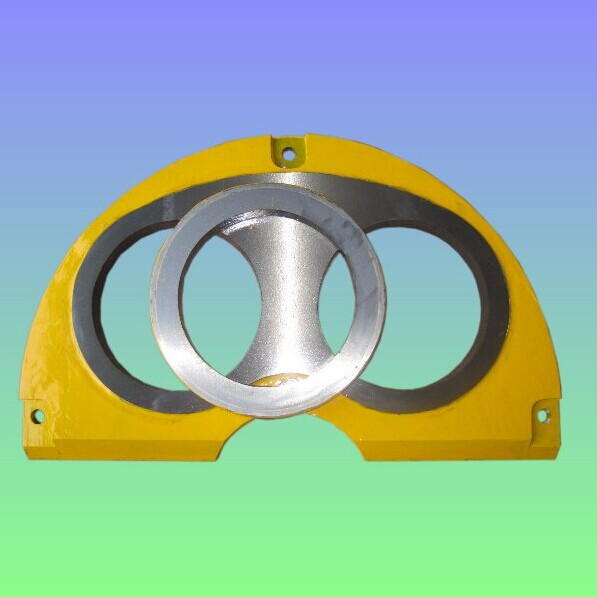

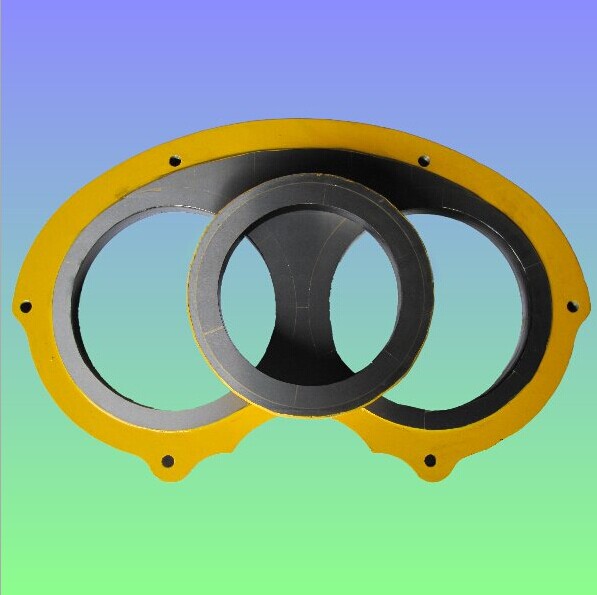

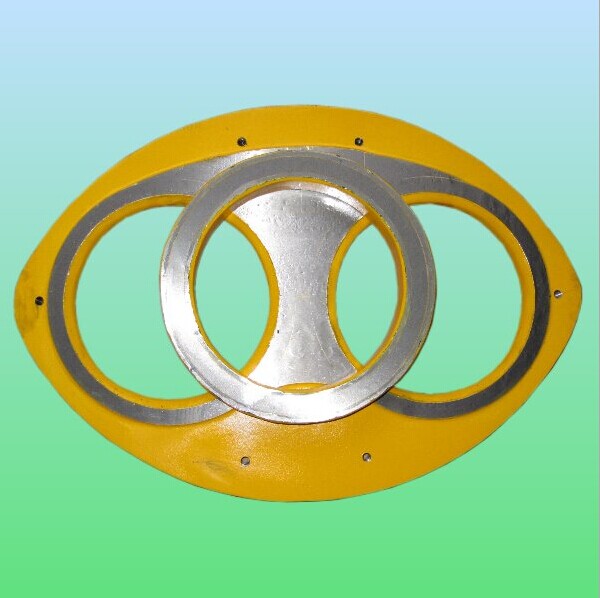

SANY Spectacle Plate and Wear Ring DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: SANY Spectacle Plate and Wear Ring DN230

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Sany concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our SANY Spectacle Plate and Wear Ring DN230 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs SANY Spectacle Plate and Wear Ring DN230 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some SANY Spectacle Plate and Wear Ring DN230 according to customers request?

A4: Yes, we can produce SANY Spectacle Plate and Wear Ring DN230 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: What are the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts?

- Using non-standard or modified hydraulic components in concrete pump spare parts can pose several potential risks. Firstly, non-standard components may not have undergone the same rigorous testing and quality control as the original equipment manufacturer (OEM) parts. This means that their performance and durability may be compromised, leading to potential failures or malfunctions. Such failures can result in accidents, injuries, or damage to the equipment or surrounding structures. Secondly, using non-standard or modified components may void the warranty of the concrete pump and its spare parts. Manufacturers typically offer warranties to ensure the reliability and safety of their products. By using non-standard components, the warranty may become null and void, leaving the user responsible for any repairs or replacements needed due to issues arising from these non-standard parts. Another risk is the potential compatibility issues that may arise when using non-standard or modified components. Hydraulic systems rely on precise engineering and compatibility between various components to function optimally. Non-standard or modified parts may not fit properly or may have different specifications, leading to leaks, pressure imbalances, or reduced overall performance. Furthermore, the use of non-standard or modified components may also impact the overall efficiency and productivity of the concrete pump. OEM parts are designed to work seamlessly with the rest of the system, ensuring smooth operation and maximum output. By using non-standard parts, the performance of the pump may be compromised, resulting in increased downtime, decreased productivity, and higher maintenance costs. Lastly, the use of non-standard or modified components may also have legal and regulatory implications. In some jurisdictions, there may be regulations or standards in place that require the use of OEM or certified parts for certain equipment, including concrete pumps. Failure to comply with these regulations can result in fines, penalties, or legal liabilities in case of accidents or failures. In conclusion, the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts include compromised performance and durability, warranty voidance, compatibility issues, reduced efficiency, and legal and regulatory implications. It is always advisable to use OEM or certified spare parts to ensure the safety, reliability, and optimal performance of the equipment.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts can vary depending on the specific part in question. However, there are some general signs that can indicate when a concrete pump spare part is experiencing wear and tear. One common sign is visible damage or deterioration on the surface of the part. This can include cracks, chips, or dents on the outer layer of the spare part. These damages can occur due to regular use, exposure to harsh environmental conditions, or accidental impact during operation. Another sign is increased vibration or noise during operation. If a concrete pump spare part is experiencing wear and tear, it may start to produce unusual vibrations or noises that were not present when it was in good condition. This can be an indicator of internal damage or misalignment of the part, which can affect its overall performance and efficiency. Reduced performance or efficiency is also a common sign of wear and tear on concrete pump spare parts. If a part is experiencing wear and tear, it may not function as effectively as before, resulting in decreased pumping capacity, reduced flow rate, or inefficient operation. This can lead to delays in construction projects and increased maintenance costs. Additionally, increased maintenance and repair requirements can indicate wear and tear on concrete pump spare parts. If a part needs to be repaired or replaced more frequently than usual, it could be a sign that it is experiencing wear and tear. Regular inspections and maintenance can help identify potential issues early on and prevent further damage to the spare parts. In conclusion, signs of wear and tear on concrete pump spare parts can include visible damage, increased vibration or noise during operation, reduced performance or efficiency, and increased maintenance requirements. It is important to regularly inspect and maintain these spare parts to ensure their optimal performance and prolong their lifespan.

- Q: Can I get spare parts for both concrete pumps with and without boom control systems?

- Yes, you can get spare parts for both concrete pumps with and without boom control systems.

- Q: How often should control system sensors be calibrated or replaced?

- The calibration or replacement frequency of control system sensors varies depending on several factors, including the type of sensor, its application, environmental conditions, and the manufacturer's recommendations. Typically, it is advisable to calibrate control system sensors at least once a year. Nevertheless, certain sensors may necessitate more frequent calibration due to their sensitivity or importance in the system. For instance, sensors used in safety-critical applications or those exposed to harsh environmental conditions may require calibration every six months or even quarterly. Furthermore, it is vital to regularly monitor the performance of control system sensors to ensure accurate readings and dependable operation. This can be accomplished through routine maintenance and periodic checks. If any indications of sensor drift, inconsistency, or failure are observed during these checks, immediate calibration or replacement may be required. Additionally, the manufacturer's recommendations play a significant role in determining the intervals at which calibration or replacement should occur. Each sensor comes with its own specifications and guidelines provided by the manufacturer. It is crucial to adhere to these recommendations to maintain optimal performance and prolong the lifespan of the sensor. In conclusion, the calibration or replacement frequency of control system sensors should be determined by considering a combination of factors, including industry standards, application requirements, environmental conditions, and manufacturer's guidelines. Regular monitoring, routine maintenance, and adherence to these factors will ensure that control system sensors operate accurately and reliably.

- Q: What are the indications of a faulty concrete pump seal?

- There are several indications that can suggest a faulty concrete pump seal. Some of the common signs include: 1. Leakage: One of the most obvious signs of a faulty seal is leakage. If you notice any leaks around the seal area, it is a clear indication that the seal is not working properly and needs to be replaced. 2. Reduced pumping efficiency: A faulty seal can lead to reduced pumping efficiency. If you notice that the concrete pump is not able to deliver the same amount of concrete as it used to, or if it takes longer to complete a job, it could be due to a faulty seal. 3. Increased noise levels: Another indication of a faulty seal is an increase in noise levels during operation. If you notice any unusual or louder noises coming from the concrete pump, it could be a sign that the seal is not sealing properly and needs to be checked. 4. Vibration or movement: Faulty seals can also lead to excessive vibration or movement in the pump. If you notice that the pump is vibrating more than usual or if it is moving around during operation, it could indicate a problem with the seal. 5. Contamination: A faulty seal can allow contaminants such as dirt, dust, or water to enter the pump. If you notice any signs of contamination in the pump, it is important to inspect the seal and replace it if necessary. It is important to address any indications of a faulty concrete pump seal promptly to avoid further damage to the pump and ensure safe and efficient operation. Regular maintenance and inspection of the seal can help prevent potential issues and extend the life of the concrete pump.

- Q: How can a faulty concrete pump cylinder affect the pumping process?

- A faulty concrete pump cylinder can have a significant impact on the pumping process. The cylinder plays a crucial role in the concrete pumping system as it is responsible for generating the necessary pressure to push the concrete through the pipes and hoses. One of the main issues caused by a faulty cylinder is a decrease in pumping efficiency. If the cylinder is worn out or damaged, it may not be able to generate sufficient pressure to push the concrete effectively. This can lead to a decrease in the pumping rate and overall productivity of the concrete pumping operation. Furthermore, a faulty cylinder can result in irregular and inconsistent flow of concrete. This can cause blockages or clogs in the pipes, leading to disruptions in the pumping process. These blockages can be time-consuming and costly to remove, as they may require the disassembly of the pumping system to access and clear the blocked area. In addition, a faulty cylinder can cause leaks in the pumping system. These leaks not only waste concrete but also reduce the overall pressure in the system, affecting the ability to pump the concrete to the desired location. Leaks can also lead to a messy worksite, posing safety risks for workers and potentially damaging surrounding structures. Moreover, a faulty cylinder can increase the risk of equipment failure. If the cylinder malfunctions or fails completely, it can cause the entire pumping system to shut down. This can result in significant downtime and delays in the concrete pouring process, leading to additional costs and potential penalties. Overall, a faulty concrete pump cylinder can greatly affect the pumping process by decreasing pumping efficiency, causing irregular flow, promoting leaks, and increasing the risk of equipment failure. Regular maintenance, inspection, and timely replacement of the cylinder are essential to ensure smooth and efficient concrete pumping operations.

- Q: How does a concrete pump piston work?

- By creating a back-and-forth movement, the concrete pump piston propels the concrete through the pump and into the desired location. The piston is a cylindrical part that fits snugly inside a cylinder and is connected to a rod, which is linked to a hydraulic system. When the hydraulic system is activated, it propels the rod forward, thereby causing the piston to move in the same direction. As the piston advances, it creates a vacuum behind it, which draws the concrete into the cylinder through an inlet valve. Once the piston reaches the end of its forward stroke, the hydraulic system changes its direction, retracting the rod and causing the piston to move backward. Consequently, this action closes the inlet valve and opens an outlet valve, enabling the concrete to be forced out of the cylinder and into the delivery line. The reciprocating motion of the piston, combined with the alternating opening and closing of the inlet and outlet valves, facilitates a continuous flow of concrete through the pump. This process is rapidly repeated, ensuring efficient and consistent pumping of concrete to the desired location.

- Q: How does a hopper agitator blade ensure smooth concrete flow?

- To guarantee a seamless flow of concrete, a hopper agitator blade is employed to mix and disintegrate any clumps or air pockets in the concrete mixture. Specifically designed to be positioned inside the hopper, the blade rotates and agitates the concrete, ensuring a homogeneous and steady state. While in rotation, the blade disperses any settled aggregates at the hopper's base, preventing blockages or uneven distribution during the pouring procedure. This uninterrupted mixing action guarantees that the concrete remains well-blended and effortlessly pours out of the hopper. Furthermore, the agitator blade aids in breaking up any air bubbles that may have formed within the concrete mixture. These air bubbles can compromise the structural integrity of the concrete and lead to an uneven final appearance. By agitating the concrete, the blade effectively releases trapped air, promoting a consistently dense mixture. In essence, a hopper agitator blade guarantees a seamless flow of concrete by effectively blending the mixture, breaking apart any clumps or air pockets, and fostering a uniform composition. This ensures that the concrete pours smoothly and evenly during the pouring process, resulting in a top-notch end product.

- Q: How often should hopper grate levers be inspected or replaced in a concrete pump?

- To ensure the proper functioning and prevent potential issues, it is necessary to regularly inspect the hopper grate levers in a concrete pump. The frequency of inspections may vary based on factors such as usage intensity, material being pumped, and operating conditions. However, a general recommendation is to conduct inspections at least once every six months or after every 500 hours of operation. During the inspection, carefully examine the hopper grate levers for signs of wear, damage, or misalignment. If any issues are identified, it is crucial to promptly replace the levers to prevent further damage to the hopper grate system or potential safety hazards. To ensure optimal performance and durability, it is essential to utilize high-quality replacement parts specifically designed for the concrete pump model. By conducting regular inspections and timely replacements of hopper grate levers, the efficiency and reliability of the concrete pump can be maintained, minimizing downtime and expensive repairs.

- Q: How long do concrete pump rubber hoses typically last?

- Concrete pump rubber hoses typically last around 1 to 5 years, depending on various factors such as usage, maintenance, and environmental conditions.

Send your message to us

SANY Spectacle Plate and Wear Ring DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords