Rv Aluminum Siding Sheets - Aluminium Circles Stocks and Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

aluminium circles include aluminium hot rolled and colod rolled, etc. they are totaly differetn from each other . we have a good reputation in the field of aluminium material, etc.

The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

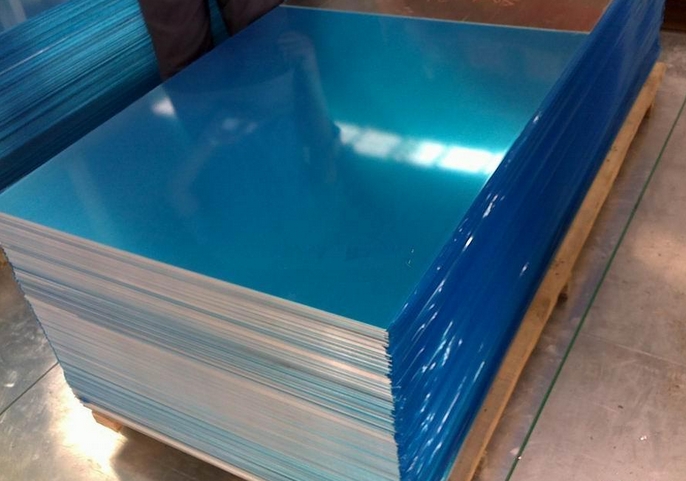

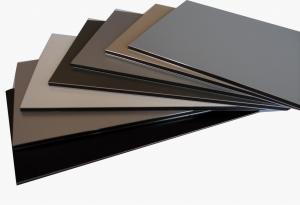

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Is it possible to utilize aluminum sheets for crafting distinctive architectural structures?

- <p>Yes, aluminum sheets can be used to create unique architectural designs. Known for their strength, durability, and lightweight properties, aluminum sheets are ideal for various architectural applications. They can be easily shaped and cut to fit specific design requirements, offering flexibility in design and construction. Additionally, aluminum's resistance to corrosion and weathering makes it a sustainable choice for long-lasting structures. Architects often use aluminum for facades, roofing, and other exterior elements due to its modern aesthetic and low maintenance needs.</p>

- Q: What are the different methods of surface printing aluminum sheets?

- There are several different methods of surface printing aluminum sheets, each with its own advantages and applications. Some of the common methods include: 1. Screen Printing: This is a popular technique where a mesh screen with a stencil of the desired design is used. Ink is then forced through the open areas of the stencil onto the aluminum sheet. Screen printing allows for high precision and vibrant colors, making it suitable for various applications such as signage, labels, and decorative purposes. 2. Digital Printing: With advancements in technology, digital printing has become a popular method for printing on aluminum sheets. This method uses inkjet technology to directly print the design onto the surface of the sheet. Digital printing offers high detail and a wide range of colors, making it suitable for customized and complex designs. 3. Offset Printing: Offset printing is a versatile method often used for high-volume production. It involves transferring the design from a plate onto a rubber blanket, which is then pressed onto the aluminum sheet. This technique provides consistent and accurate printing results and is commonly used for packaging, labels, and large-scale printing. 4. Flexographic Printing: Flexographic printing is a cost-effective method commonly used for printing on flexible materials, including aluminum sheets. It involves using flexible relief plates with the desired design, which are then pressed onto the sheet. Flexographic printing is suitable for large-scale production and is often used for packaging materials and labels. 5. Gravure Printing: Gravure printing, also known as rotogravure printing, is a method that uses engraved cylinders to transfer ink onto the aluminum sheet. This technique is known for its high quality and ability to reproduce fine details. Gravure printing is commonly used for high-end packaging, decorative items, and high-resolution images. 6. Embossing: While not technically a printing method, embossing is a popular technique used to create raised designs or patterns on aluminum sheets. This can be done through mechanical or heat processes, creating a three-dimensional effect. Embossed aluminum sheets are often used for decorative purposes, architectural applications, or to enhance the grip on surfaces. These are just some of the methods used for surface printing aluminum sheets. The choice of method depends on factors such as the desired design, level of detail, quantity, budget, and intended application.

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping. Aluminum is generally not recommended for handling certain chemicals due to its reactivity and potential for corrosion. It is more commonly used in industries that require lightweight materials and good thermal conductivity, such as aerospace or construction. For chemical transfer piping, it is advisable to use materials that are resistant to corrosion and can withstand the specific chemicals being transported, such as stainless steel, PVC, or high-density polyethylene (HDPE).

- Q: Can aluminum sheets be used for decorative ceiling panels?

- Yes, aluminum sheets can be used for decorative ceiling panels. Aluminum is a versatile material that can be easily shaped, colored, and textured, making it ideal for creating visually appealing and modern ceiling designs. Additionally, aluminum is lightweight, durable, and resistant to corrosion, making it a practical choice for long-lasting decorative ceiling panels.

- Q: Are aluminum sheets suitable for food processing applications?

- Aluminum sheets are indeed suitable for food processing applications. The reason behind their popularity in the food processing field lies in their outstanding properties, which include corrosion resistance, thermal conductivity, and low reactivity with food substances. These sheets find widespread use in a variety of food processing equipment, such as storage containers, cooking utensils, and packaging materials. Moreover, aluminum sheets are lightweight and easy to clean, while also possessing excellent heat distribution properties. This makes them ideal for applications that necessitate precise temperature control during food processing. Furthermore, the use of aluminum ensures food safety and prevents any potential contamination, as it is a non-toxic material. All in all, aluminum sheets are a dependable and extensively employed material within the food processing industry.

- Q: What are the safety standards for aluminum sheets utilized in construction?

- <p>Yes, there are safety standards for aluminum sheets used in construction. These standards ensure the material's quality, strength, and suitability for various applications. They include specifications for thickness, alloy type, and surface treatment. International standards such as ASTM B209 (for aluminum sheet and plate) and EN 485 (for aluminum and aluminum alloy sheets) govern the production and use of aluminum sheets in construction. Compliance with these standards is crucial for safety, durability, and to meet regulatory requirements in different regions.</p>

- Q: I am looking at buying a used 1983-84 Eldorado but have read some things about the reliability of the aluminum engine. Any thoughts? Thanks.

- 1984 Cadillac

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- Funny you should ask...I was reading the labels just yesterday on my deods also! Old Spice has Alum Hydroxide...Brut has Popylene Glycol and Old Spice High Endurance has Dipropylene Glycol. Ususally the 1st ingredient that you read on the label tells what it is the main ingredient. I prefer Brut!

- Q: Where is a good website to get a brand new sealed in box Aluminum macbook.

- there are none, i know i sucked it up and went to apple, worth every penny. good luck!

Send your message to us

Rv Aluminum Siding Sheets - Aluminium Circles Stocks and Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords